ASME B30.9-2018: Updates & Revisions to ASME’s B30.9 Slings Standard

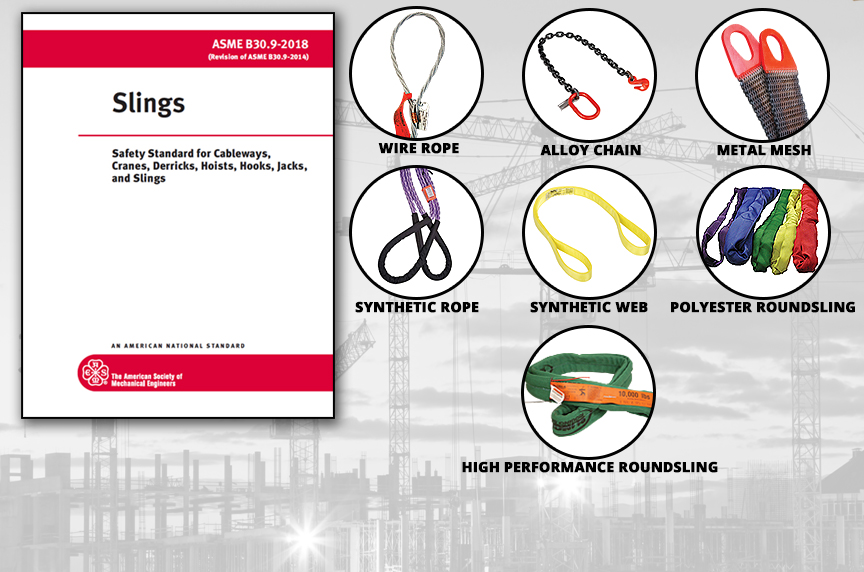

ASME B30.9 Slings is specific to load-handling lifting slings used to connect to and support a heavy load. The B30.9 standards address the specification, buying, maintenance, training and safe use of wire rope slings, alloy chain slings, metal mesh slings, synthetic rope slings, synthetic web slings, polyester roundslings, and high-performance roundslings.

The American Society of Mechanical Engineers (ASME) is a professional association and leading international developer of codes and standards associated with the art, science, and practice of mechanical engineering. ASME membership is comprised of engineers, scientists, government officials, and others who voluntarily contribute their technical expertise.

ASME standards and safety codes are intended to enhance public safety and offer best practices and applicable regulations within specific industries and jurisdictions. ASME standards are accredited as meeting the criteria of the American National Standards Institute (ANSI).

ASME B30 is identified as the “Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings.” Every couple of years, the B30 Committee reviews, revises, and amends their existing standards and releases a new edition. The Committee revises the standards based on numerous considerations, including:

- Technological advances

- New Data

- Changing environmental and industry needs

In this article, we’ll discuss the revisions, updates, and additions to the newly released ASME B30.9-2018 Slings standard, compared to the previously released 2014 edition.

What Is ASME B30.9-2018 Slings?

ASME B30.9 Slings is specific to load-handling lifting slings used to connect to and support a heavy load. The B30.9 standards are intended to be used by manufacturers, owners, employers, users, and others concerned with the specification, buying, maintenance, training and safe use of slings and hooks with B30 equipment, plus all potential governing entities.

In the lifting and rigging industries, ASME B30.9 is one of the most commonly-referenced standards that applies to the fabrication, attachment, use, inspection, testing, and maintenance of slings used for load-handling purposes. The variety of different lifting slings that this standard applies to are:

- Wire rope slings

- Alloy chain slings

- Synthetic rope slings

- Metal mesh slings

- Synthetic web slings

- Synthetic roundslings

The first ASME B30.9 standard was issued in 1971 and since then, new editions have been revised and published by the B30 Committee in 1984, 1990, 1996, 2003, 2006, 2010, and 2014.

The new ASME B30.9-2018 Slings revises and supersedes the previous 2014 edition of the same standard.

What’s New in ASME B30.9-2018 Slings?

The new 2018 revision now includes guidance concerning the inspection of stored slings, rigger responsibilities, and an entirely new chapter (Chapter 9-7 High Performance Roundslings)—which have never been included in the B30.9 standards prior to 2018. If you’re interested in purchasing ASME B30.9-2018 Slings, you can buy a physical book or download a digital copy in the ASME webstore.

ASME defines the fabrication method as: “high performance roundslings shall be fabricated from core yarns wound together with multiple turns and enclosed in a cover(s). Covers shall be made from synthetic material.”

ASME also provides further clarification on the differences between “shall” and “should”—clarifying that “shall” is a requirement and “should” is a recommendation.

Among these changes listed above, the following additions, revisions, or changes are also listed on the ANSI blog:

Additions:

- Chapter 9-7 High Performance Roundslings: Selection, Use, and Maintenance

- Definitions for the terms “denier,” “high tenacity fiber,” “original language(s),” “shall,” “should,” and “tenacity.”

- New section on “Rigger Responsibilities.”

- Guideline that slings in severe or special service should be inspected before each use.

- Guideline for maintaining a written record of the most recent periodic inspection of slings.

- Guidelines for finishing fitting surfaces to remove edges in clause on wire rope, synthetic rope, synthetic webbing, metal mesh slings, and polyester roundslings.

- New section on sling components that employ wire rope slings other than those listed in the standard.

- New section on methods of fabrication for wire rope slings.

Revisions

- Entire section on “Original and Translated Technical and Safety-Related Information” was revised.

Clarifications:

- A qualified person should, if necessary, determine additional steps that need to be taken after identifying a hazard during inspection.

- A polyester roundsling does not need to be removed due to knots in the roundsling when there are core yarn knots inside the cover installed by the manufacturer during the fabrication process.

Removals:

- Guideline prohibiting slings made with wire rope clips being used as a choker hitch.

Wrapping it Up

Prior to each use, all types of lifting slings need to be inspected for damage or irregularities to help avoid costly downtime and help to keep everybody on the job site safe. Routine inspection should be looked at as an investment that, over time, will help keep valuable equipment running and keep workers safe.

At Mazzella, we provide rigging equipment, rigging inspection services, and rigging/operator training to workers in all types of industries. We have locations scattered throughout the eastern half of the United States that provide specialized lifting and rigging services to industries like energy, construction, automotive, steel, naval and maritime, and mining.

If you have questions about the proper type of lifting sling you should be using for your application, or you want to get better service life out of the slings you’re currently using, contact a Lifting Specialist at a location nearest you.

Copyright 2018. Mazzella Companies.