Plasma Synthetic Rope: Versatility for Lifting, Winching, and Mooring

Plasma® rope can be used similar to wire rope as the primary medium used for overhead lifts, towing, mooring, and winching. The rope fibers can be designed and constructed in a variety of ways to provide mechanical advantages including strength, weight-savings, durability, and flexibility.

The world of high-performance synthetic rope is quickly evolving and becoming not only acceptable, but preferred in more and more lifting, rigging, and winching applications. As a manufacturer and distributor of a number of different lifting and rigging products, we’ve seen the benefits that synthetic rope can provide to customers in certain applications. When compared to wire rope and other steel lifting mediums, Plasma® Synthetic Rope offers:

- Equal or greater strength

- Significant weight-savings

- Greater flexibility

- Low risk of recoil

- Non-corrosive and safer to handle (no broken wires)

- Buoyant in water

In this article, we’ll provide you with a better understanding of what Plasma® Synthetic Rope is, the different types of applications it can be used for, and the advantages and disadvantages when compared to more traditional steel rope and lifting slings.

What Is Plasma Synthetic Rope?

Plasma® Synthetic Rope is manufactured from High Modulus Polyethylene (HMPE) that has been enhanced by a patented recrystallization process. This process draws the precisely twisted strand through a heated fluid-filled pressurized vessel—creating a constant heat profile throughout the strand’s cross-section. This process ensures that all filaments are effectively increasing fiber strength efficiency throughout the strand. Finally, a polyurethane finish is applied to the rope to improve snag resistance and sunlight resistance.

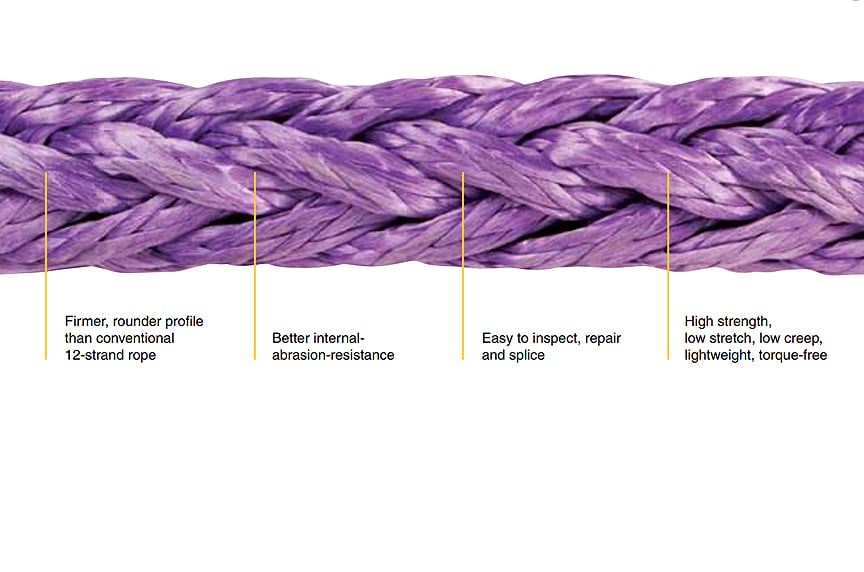

The patented Plasma® 12×12 ropes are constructed of a 12-strand braided rope in which each of the 12 strands is a 12-strand rope, or braided primary strand. This construction provides the user with the following benefits:

- Long lay lengths

- Flexible design for bending applications

- Easy to inspect

- Easy to splice and repair using standard 12 strand splicing techniques

- High-strength translation efficiency for medium to large diameter ropes

Plasma® rope can be used similar to wire rope as the primary lifting medium used for overhead lifts. The rope fibers can be designed and constructed in a variety of ways to provide different mechanical advantages for lifts—including creep and fatigue-resistance and ultimate flexibility for bending over sheaves and spooling around a drum or winch.

Synthetic rope slings can also be constructed from Plasma® 12×12 braided construction to create lifting slings that are extremely strong, durable, lightweight, and flexible. With synthetic rope slings, you get the strength and durability of wire rope slings, plus the weight-savings and load protection of synthetic roundslings—all in one product.

What Is Plasma Synthetic Rope Used For?

Plasma® Synthetic Rope has become more widely-accepted due to its versatility, strength, and flexibility. There are a number of different applications where synthetic ropes can be used for lifting, pulling, mooring, or winching—including those in the construction, shipyard, mining, and offshore and deepwater industries.

Let’s take a look at some of the most common applications for Plasma® Synthetic Rope:

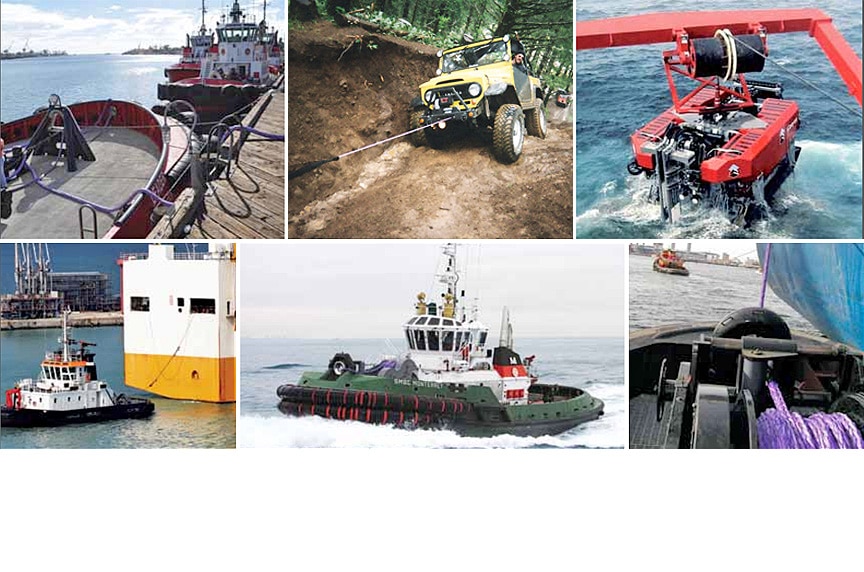

Offshore Working and Lifting Lines

Plasma® Rope can be used in a wide range of offshore working and lifting applications, including deepwater mooring lines, oceanographic lifting and coring ropes, seismic tow ropes, and salvage ropes.

Buoy Mooring Systems

Cables or lines can be configured with varying buoyancy, fatigue-resistance, and stretch properties for buoy mooring in marine geology, oceanography, and meteorology projects.

Tug and Salvage Lines

Synthetic ropes can be used for ship assist, towing, and escort jobs. Both the pendant line and the mainline can be comprised of synthetic rope fibers suitable for any tug or salvage application.

Inland River Lines

Wing wires and face wires are the lines that pushboats use to attach themselves to barges and maneuver them up or down a river system. Plasma® Synthetic Ropes can be used to replace wire rope used for wing wires or face wires.

Ship and Barge Mooring Lines

Synthetic rope lines can be used to moor a ship or barge alongside a berth, buoy, or floating platform. A wide range of mooring lines can be made-to-order based on strength, length of line, and expected load requirements.

Mining Tow Lines

Plasma® Synthetic Ropes can replace and outperform wire rope when recovering vehicles or heavy equipment that is stuck in the mud or lodged in a difficult or dangerous place.

Utility Pulling Lines and Cable Grips

Electrical utility companies or utility contractor companies use Plasma® Ropes to pull utility transmission wires through blocks and into place on transmission towers using large winches.

Utility and RV Winches

High-performance synthetic fiber ropes can be used for vehicle recovery winch lines, ATV winch lines, and tow ropes. Non-metallic, non-conductive fiber ropes can also be used for utility applications including pulling overhead power lines and setting poles for transformers.

Theatrical Rigging Lines

Synthetic ropes can be used in theatrical and performance productions for winch lines, reliable human flight, and everything in-between. They’re strong, yet soft on the hands and can be custom-built for any job or performance.

Commercial Fishing Lines

A wide range of synthetic fiber ropes can be used for commercial fishing lines including trawl ropes, gilsons, purse lines, and aquaculture.

Emergency Towing

Emergency tow packages are available with a rope assembly including a Plasma® tow line with thimble eyes, floating pickup line, and lighted buoy—all stored in a waterproof container.

What Are the Advantages of Plasma® Synthetic Rope?

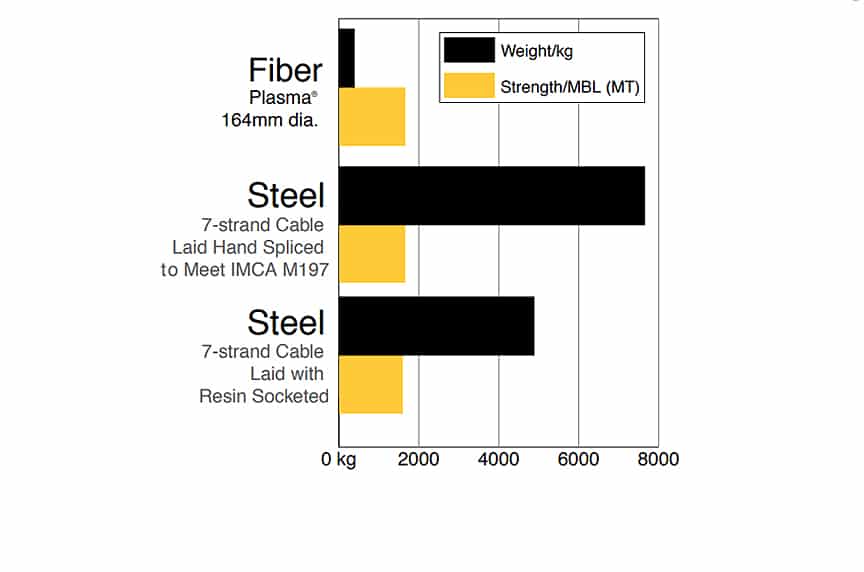

Plasma® Synthetic Rope offers all of the advantages of steel wire rope, without the inherent hazards, and is 1/7 the total weight of comparably specified wire rope. They can be more expensive than wire rope or conventional synthetic ropes, but can offer longer service life and safety due to their ease of handling, flexibility, and weight-savings.

Let’s take a look at some of these advantages and why a Plasma® Synthetic Rope might be the right choice for your next lifting, towing, or winching project.

Strength and Durability

In most cases, Plasma® Rope has equal or greater strength, size for size, when compared to wire rope. Because synthetic ropes are made of fibers and not metal, they’re resistant to corrosion and can tolerate almost any natural element, including UV rays, rain, snow, ice, and freezing or high temperatures. They’re also resistant to chemical exposure such as bleaches and some acids, and also perform well in fresh water or salt water applications due to their neutral buoyancy and resistance to liquid absorption.

When used for winching applications (and when following the manufacturer’s recommendations for proper installation, use, and care) Plasma® 12-strand ropes can provide longer service life and better performance than wire rope. Lighter than steel, and easier on the hands, Plasma® ropes spool up flat and pull off the drum easier than steel. Also, since Plasma® Rope doesn’t have a core, the bottom layer of rope on a drum won’t crush like wire rope can.

Lightweight and Flexible Design

Diameter for diameter, an HMPE synthetic rope is going to be about 1/7 the weight of a wire rope with comparable specifications. Plasma® Rope is braided in a torque-free construction, resulting in an ultra-flexible design that also has a low D:d ratio efficiency for smooth spooling and high fatigue-resistance when bending over sheaves.

When manufactured into a sling, it can be more ergonomic for the rigger due to the weight-savings when hauling and connecting rigging to the hook and to the load versus a comparable steel wire rope sling or alloy chain sling.

Safety

Another major benefit of Plasma® Synthetic Rope is the rope doesn’t store as much built-up energy as steel does. In the event that a break or failure occurs, there is no whipping or recoil motion of the rope, or projectiles that could injure nearby workers. When a steel rope or chain breaks, the reaction is often violent and explosive and can potentially injure workers or damage nearby equipment. When a Plasma® Rope breaks, the line simply falls to the ground.

Also, the fibers in a synthetic rope are soft and the user doesn’t have to worry about broken wires, metal burrs, or corrosion that could potentially injure or cut a worker while the rope is being handled.

Available Protection Options

Plasma® 12 and other synthetics ropes can be good for virtually any application, due to advancements in protections against chaffing, cutting, and abrasion. There are a variety of products on the market that offer different ranges of protection at different price points, so you can find the right protection for your specific lifting, towing, or mooring application.

Inspection and Repairs

Unlike wire rope and synthetic slings with outer jackets, synthetic ropes are easy to inspect. Splicing or repairs can be performed in the field with basic tools and minimal time—using a simple lockstitch type splice, 4-3-2, or 5-4-3 tuck splice.

What Are the Disadvantages of Plasma Synthetic Rope?

Plasma® Ropes may not be the best choice for every project—here are some reasons that Plasma® may not be the best choice for certain applications.

Price

HMPE synthetic slings are almost always going to be more expensive pound for pound vs. steel options. Whether you’re buying long lengths of rope for winching, lifting, and mooring or you’re using it to construct synthetic rope slings, high-performance Plasma® rope will cost you more—especially when you factor in the cost of adding abrasion and cutting protection to get similar protection and durability to that of which a steel product would offer.

Abrasion and Cutting

Like we mentioned earlier, there are a number of different protection options available for Plasma® and other synthetic ropes. These should be used when the possibility of cutting or abrasion exists, like when lifting heavy metal sheets or when lifting loads with sharp edges.

Also, when used on winches, you should make sure that winch surfaces—including flanges and barrels—are kept clean and are not rusted or corroded. Dirt, grit, or corrosion can cause abrasion to the rope when it is deployed or retrieved during winching and can cause premature wear to the individual strands of the rope.

You should also make sure that the rope is kept clean by periodically washing it with a low PH or mild detergent to remove sharp particulates and grit.

Durability

Steel wire rope will always be more durable than a synthetic fiber rope when push comes to shove. Lifting slings manufactured from alloy chain or wire rope will be able to better hold up to the rigors of heavy, bulky, and repetitive lifts in extreme and abusive operating environments.

Lower Heat-Resistance

Plasma® fibers have a relatively low softening and melting point and should not be used in applications in which high ambient, reflected, or friction-manufactured heat is anticipated or prevalent. High sustained loads on HMPE ropes under approximate temperatures of 65°C or 150°F may cause creep and strength loss.

Twist / Rotation-Resistance

Plasma® 12-strand ropes are braided from alternative left and right hand “twist” lays. Inducing twist into the braided rope lowers both the strength (reducing the balanced construction), and also makes the “opened” twist strands more susceptible to abrasion and cutting. The manufacturer recommends that end-users should attempt to remove any twist and rotation from a braided Plasma® rope or lifting sling before use.

Wrapping it Up

The strength, versatility, and lightweight properties of Plasma® Synthetic Rope allow it to be considered as a replacement for wire rope in a number of different applications. Since it can resist corrosion and can tolerate almost any natural element—including UV rays, rain, snow, ice, and freezing or high temperatures—it can be an excellent choice for certain deepwater lifting, marine, mooring, and winching applications.

If you’re interested in more information on Plasma® ropes or slings, or any of our other lines of synthetic ropes, please contact us to speak with a Lifting Specialist.

Images courtesy of Cortland. Visit their website to learn more about synthetic ropes and lifting slings.

Copyright 2018. Mazzella Companies.