Why Sheave Design is Critical to Wire Rope Service Life

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

The guideline to follow is this: the most practical design is the one that most closely accommodates the limiting factors imposed by the equipment, the operating conditions and the wire rope.

Bending Wire Rope Over Sheaves & Drums

All wire ropes operating over sheaves and drums are subjected to cyclic bending stresses, thus the rope wires will eventually fatigue. The magnitude of these stresses depends—all other factors being constant—upon the ratio of the diameter of the sheave or drum to the diameter of the rope.

Frequently, fatigue from cyclic, high-magnitude bending stress is a principal reason for shortened rope service. In order for a rope to bend around a sheave, the rope’s strands and wires must move relative to one another. This movement compensates for the difference in diameter between the underside and the top side of the rope, the distance being greater along the top side than it is on the underside next to the groove.

Proper rope movement (and service) is adversely affected if the wires cannot adjust to compensate for this length differential. Also, there can be additional limitations to wire movement because of excessive pressure caused by a sheave groove diameter which is too small, or by lack of rope lubrication. Avoid changing the bending direction from one sheave to another as this reverse bending further accelerates wire fatigue.

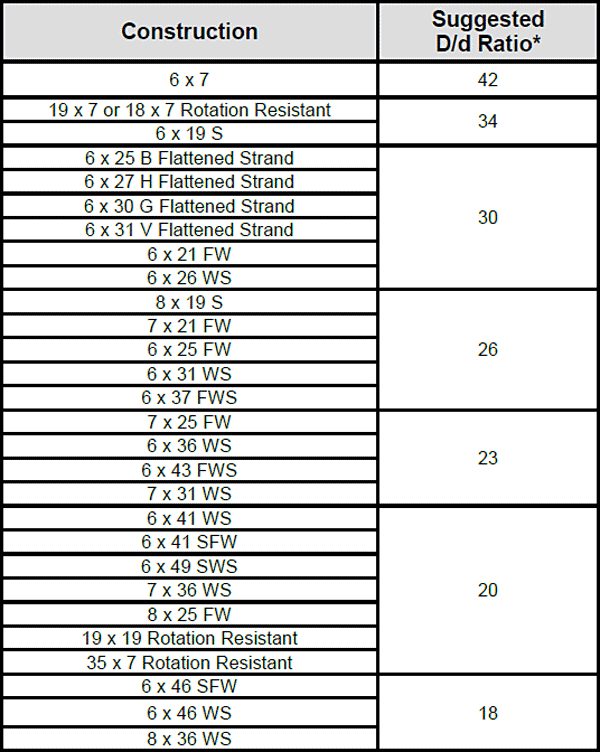

The relationship between sheave diameter and rope diameter is a critical factor that is used to estimate the rope’s fatigue resistance or relative service life. It is expressed in the D/d ratio mentioned earlier in which D is the pitch diameter of the sheave and d is the diameter of the rope. Table 1 lists suggested minimum D/d values for various rope constructions. Smaller values can affect rope life. Table 2 (on next page) shows the effect of rope construction and D/d on service life.

Suggested Sheave & Drum Ratios

These D/d ratios are based on sheave and drum diameters being approximately 400 times the outer wire diameter of the rope. For rope constructions not listed, consult your Lifting Specialist.

To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d).

For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″.

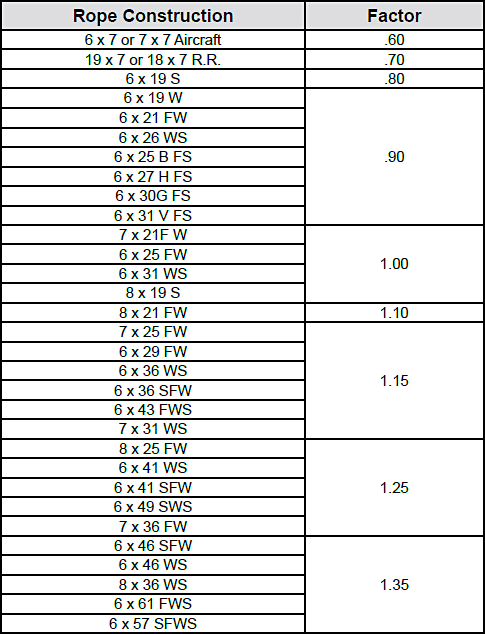

Relative Bending Life Factors

Breaking In a New Wire Rope

A new wire rope requires careful installation and following all the appropriate guidelines previously noted. After the rope is installed and the ends secured in the correct manner, the equipment should be started carefully and then permitted to run through a cycle of operation at very slow speed.

During this trial operation, closely watch all working parts—sheaves, drums, rollers—to make certain that the rope runs freely, and without any possible obstructions as it makes its way through the system. If no problems appear in running the rope, the next step should include several repetitions of the normal operational cycle under increasing loads and speeds.

This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions. Taking the time and effort to perform these breaking-in procedures should result in obtaining the optimum service life from the wire rope.

Bending-Life Factor

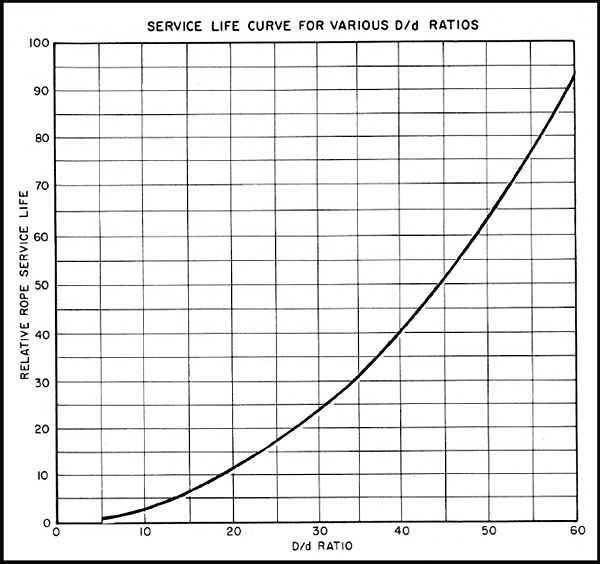

Bending-Life Factors (shown in the relative service curve) provide a comparison of the service life of different constructions under repeated bending stresses.

This service life curve only takes into account bending and tensile stresses. This curve can be utilized to predict comparative service life of a specific wire rope with varying D/d ratios.

That resultant comparison is illustrated by the following example: A rope working with a D/d ratio of 26 has a relative service life of 17. If the same rope works over a sheave that increases its D/d ratio to 35, the relative service life increases to 32.

In short, if this rope is used on the larger sheave, one could estimate an increase in its bending service life from 17 to 32 or an 88% increase.