Crane, Trolley, & Dock Bumpers

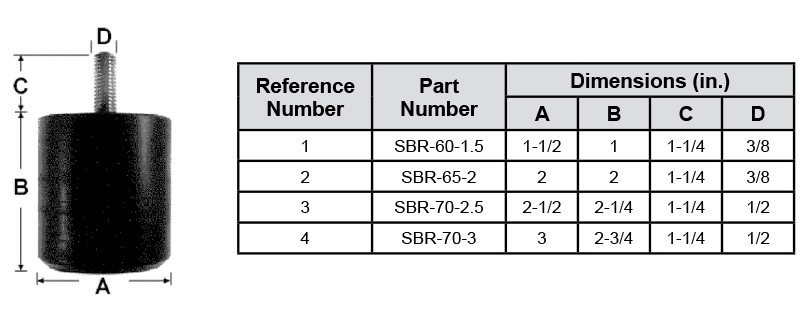

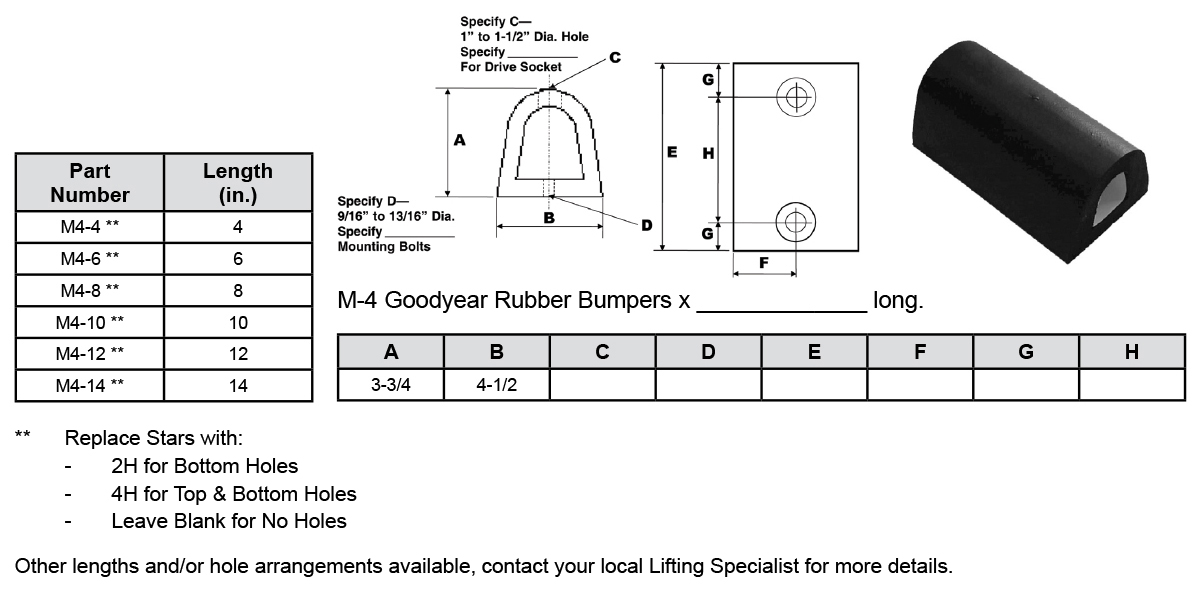

We provide crane, trolley, and dock bumpers for all types of overhead cranes. Please see the chart below for ordering information. All crane bumpers are in stock and ready for delivery.

M4 Heavy-Duty Crane Bumpers

Modern, heavy-duty production cranes have increased in size and speed over recent years. The hydraulic crane bumper was developed to transform the crane’s impact or kinetic energy into heat. The device brings the crane to rest in a controlled manner, minimizing end forces. This has rendered simple mechanical devices, such as springs or rubber bumpers, obsolete on all but the lightest crane applications.Several codes and standards have evolved that specifically identify the criteria for safely decelerating a moving crane or transfer vehicle. Among these are AIST, CMAA, OSHA, DIN, CEM, etc. There has been a rapid development of hydraulic bumpers with capacities and stroke lengths to meet the demands of increasing crane weights and speeds.The hydraulic bumper is the most economic and reliable method for limiting the forces transmitted during an impact. Structural engineers can now confidently evaluate the forces from longitudinal impact and utilize the hydraulic bumper to reduce overall structural steel costs in a building.

Modern, heavy-duty production cranes have increased in size and speed over recent years. The hydraulic crane bumper was developed to transform the crane’s impact or kinetic energy into heat. The device brings the crane to rest in a controlled manner, minimizing end forces. This has rendered simple mechanical devices, such as springs or rubber bumpers, obsolete on all but the lightest crane applications.Several codes and standards have evolved that specifically identify the criteria for safely decelerating a moving crane or transfer vehicle. Among these are AIST, CMAA, OSHA, DIN, CEM, etc. There has been a rapid development of hydraulic bumpers with capacities and stroke lengths to meet the demands of increasing crane weights and speeds.The hydraulic bumper is the most economic and reliable method for limiting the forces transmitted during an impact. Structural engineers can now confidently evaluate the forces from longitudinal impact and utilize the hydraulic bumper to reduce overall structural steel costs in a building.

Crane and Industrial Buffers: Large versions of the Fluidicshok with coil spring reset. Capacities of up to 14,000,000 inch-pounds are available in a heavy-duty mill-type design. Over 60 sizes are standard. Long stroke buffers are available with up to 120 inch deflections and capacities to one hundred million inch-pounds, making this the highest capacity standard shock absorber in the world.

Crane and Industrial Buffers: Large versions of the Fluidicshok with coil spring reset. Capacities of up to 14,000,000 inch-pounds are available in a heavy-duty mill-type design. Over 60 sizes are standard. Long stroke buffers are available with up to 120 inch deflections and capacities to one hundred million inch-pounds, making this the highest capacity standard shock absorber in the world.

Self-Compensating

ACE Controls self-compensating shock absorbers are highly engineered, fixed, multi-orifice units that decelerate moving weights smoothly, regardless of changing conditions, and require no adjustment. These versatile performers offer wide effective weight ranges for handling a wider range of applications and increased velocities.As a moving load impacts the shock absorber, the piston travels through the stroke and forces hydraulic fluid through the multi-orifice inner tube. The total orifice area decreases at a rate consistent with the decay of impact velocity, resulting in true linear deceleration.

Adjustable

The standard adjustable ACE shock absorber is based on the multiple-orifice design principle and includes a series of orifices machined along the length of a fixed inner tube. The MAGNUM® Group adjustable shock absorber, shown to the right, has a stationary metering tube, with an inner tube that rotates upon adjustment. These unique models offer dual adjustability by turning the stop collar or the hex socket adjuster at the rear.The adjustable shock absorber offers flexibility in application design and selection procedure. When an effective weight change is required, one simply adjusts the setting. The total orifice area changes, providing true linear deceleration.

Call us at 800.664.3380 or click here if you need to speak with one of our Crane Specialists!

Still Have Questions?

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.