Description

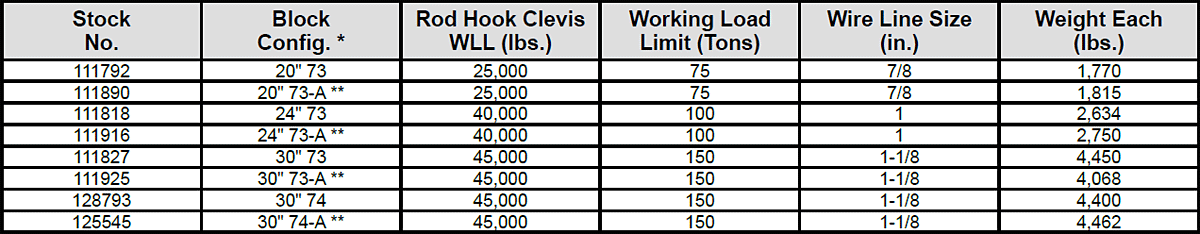

The 70 Series has a spring loaded hook that is better for heavy usage and larger depths. Tends to last longer since the shock loads are somewhat absorbed. Also available with Rod Hook Clevis.

* Spring loaded duplex hook assuring ample travel for efficient tubing operations.

No load carrying threads.

** A = Rod Hook Clevis attachment standard.