How Much Does Lifting and Rigging Training Cost?

Whether you’re budgeting for compliance or comparing training providers, this page gives you the transparency most won’t.

You’ll see exactly what affects training costs, what’s included in each course, and how to get the best value — without cutting corners, overpaying for brand names, or facing hidden fees. You’ll also understand the differences between Mazzella’s flexible, compliant training and specialized options like ITI, so you can choose the right fit for your team, your risks, and your budget.

Lifting & Rigging Training Pricing

| Session Length | Basic Rigging & Inspection or Signalperson | Crane Operator |

|---|---|---|

| 1 Hour | $125 – $175 Per Person | N/A |

| 2 Hours | $150 – $200 Per Person | N/A |

| 3 Hours | $200 – $275 Per Person | N/A |

| 4 Hours | $225 – $300 Per Person | $225 – $300 Per Person |

| 6 Hours | $325 – $400 Per Person | N/A |

| 8 Hours | $400 – $475 Per Person | $3,500 – $5,000 Per Session (Up to 10 People) |

What’s Included In Your Lifting and Rigging Training?

- Overhead crane operator training.

- Use, care, and inspection of rigging equipment.

- Signalperson training.

- More training options through our partnership with ITI.

- Comprehensive and documented training programs meet all requirements of OSHA, ASME, CMAA, and ANSI.

- Mazzella and ITI can also help you with additional training courses, ranging from lift planning, rigging engineering, and even NCCCO Certification.

Factors That Affect Training Costs

Contact Our Training Team

Frequently Asked Questions

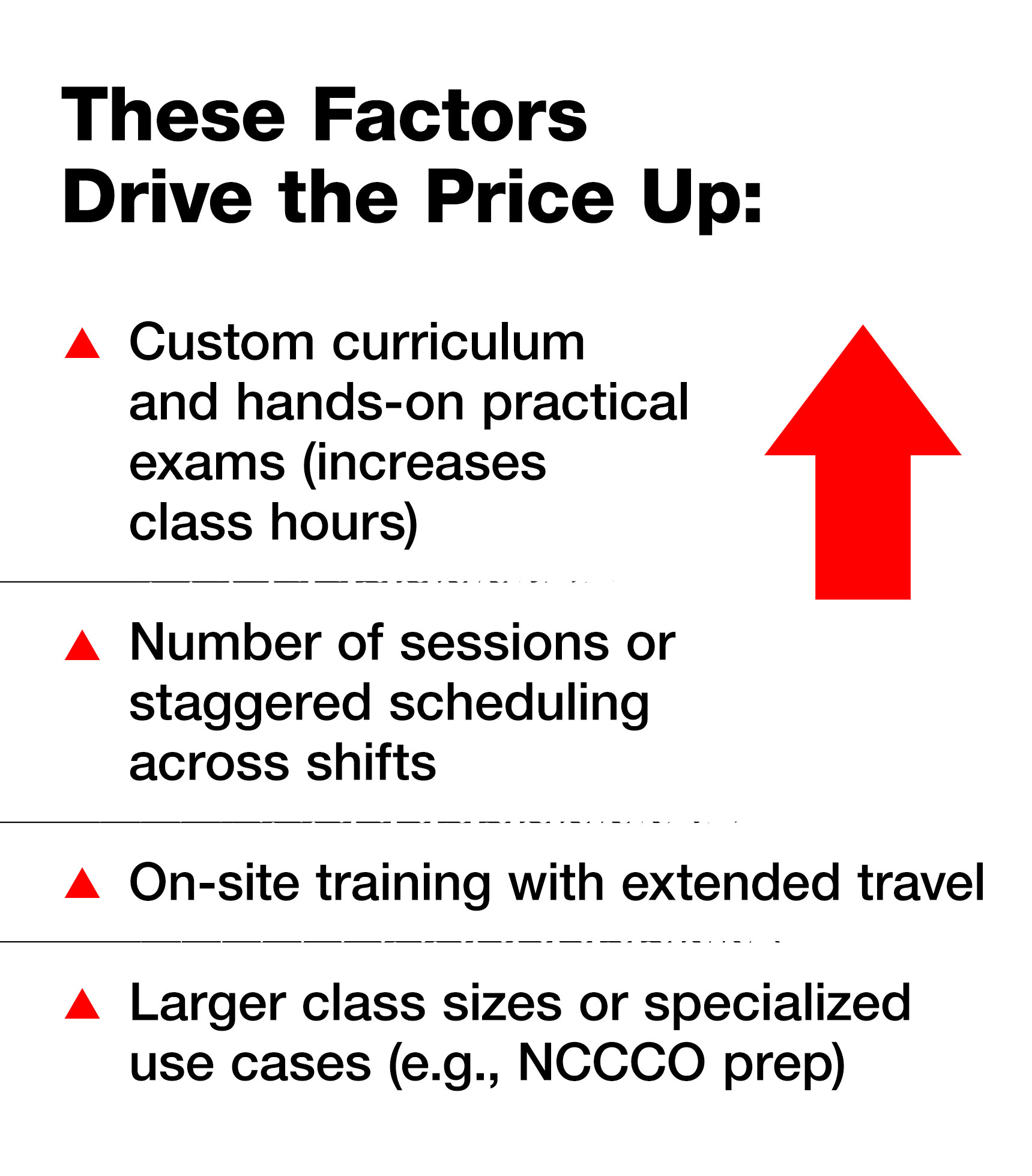

What factors drive the price up?

The cost of your lifting and rigging training depends on a number of variables:

- Custom curriculum and hands-on practical exams (increases class hours).

- Number of sessions or staggered scheduling across shifts.

- On-site training with extended travel.

- Larger class sizes or specialized use cases (e.g., NCCCO prep).

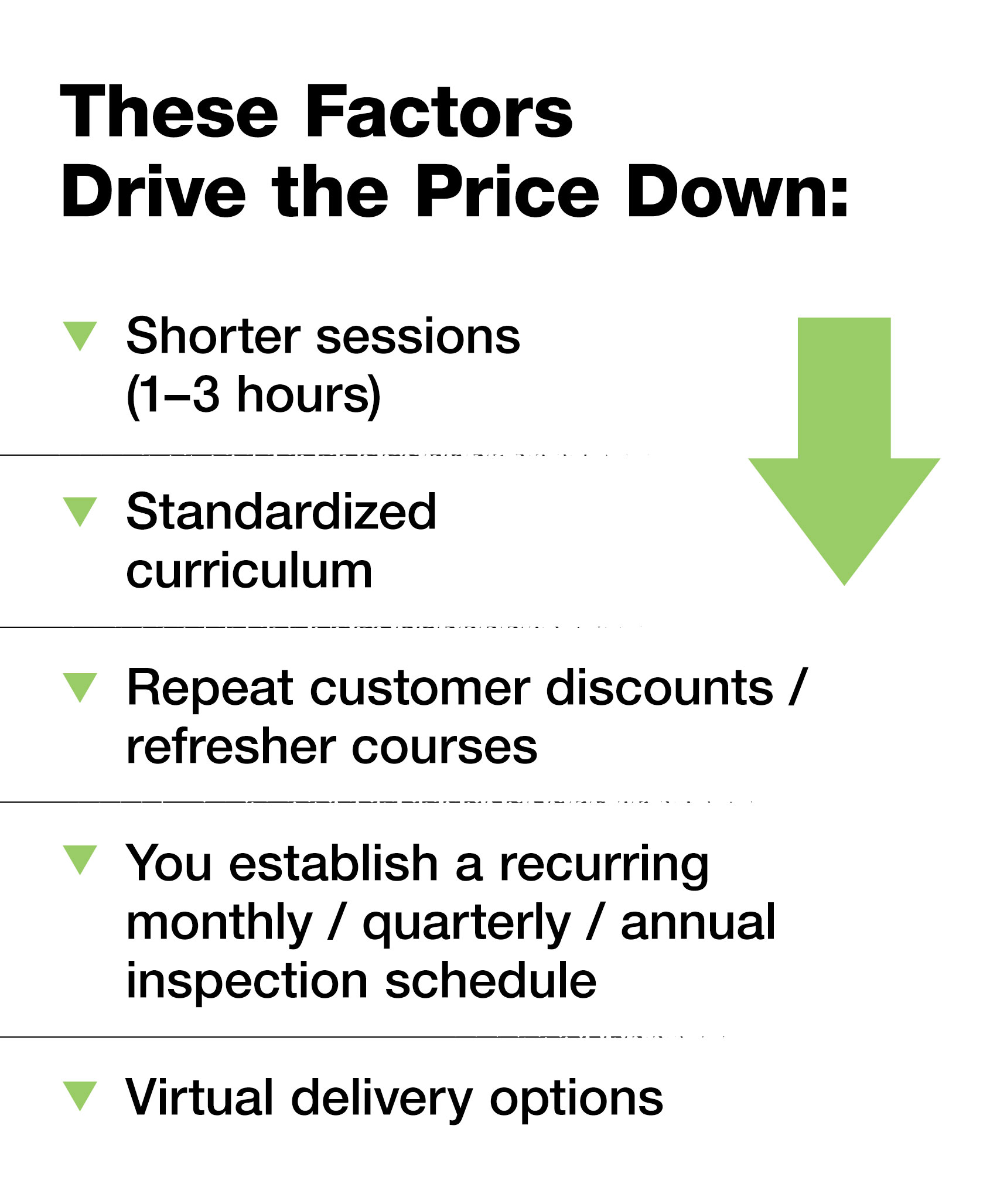

What factors drive the price down?

Looking to keep costs down? These factors can help lower your training investment:

- Shorter sessions (1–3 hours).

- Standardized curriculum.

- Repeat customer discounts / refresher courses.

- You establish a recurring monthly / quarterly / annual inspection schedule.

- Virtual delivery options.

What makes some training providers more expensive?

Some training providers charge more — and sometimes, there’s a good reason.

Companies like Industrial Training International (ITI) specialize exclusively in lifting education. Their courses are more rigorous, their instructors often have decades of field experience, and their curriculum is designed for advanced roles like Lifting Director or Rigging Engineer.

On the other hand, some providers charge premium prices because of their brand name or rigid training model — not necessarily because the content is more valuable.

At Mazzella, we do both. We offer high-quality, OSHA-compliant training delivered by experienced professionals — ideal for new hires, compliance refreshers, and basic through intermediate lifting teams. And if your needs require ITI-level rigor, we can sell and support that too. In fact, all our trainers are certified on ITI’s curriculum and teaching style.

Key Reasons Other Providers May Cost More:

- Advanced-level training and certification programs (e.g., ITI’s Master Rigger).

- Dedicated training facilities with higher overhead.

- Brand recognition.

- Rigid course structures that limit customization.

What makes some training providers so cheap?

Training may come at a lower cost due to:

- Free “awareness-level” courses used as marketing tools.

- Self-paced or virtual-only formats with no instructor interaction.

- No practical exams or hands-on assessments.

- Minimal or no documentation of competence.

- No travel or on-site support offered.

- Trainers with less field or instructional experience.

- Use of generic, pre-recorded modules without customization.

Caution: Free or ultra-cheap training often does not meet OSHA / ASME compliance, especially when no documentation, practical evaluation, or instructor-led engagement is included.

What lifting and rigging training is required, and how often?

OSHA 29 CFR 1910.179(b)(8) requires that only designated personnel be permitted to operate a crane. OSHA defines designated at OSHA 1910.179(a)(35) as: Selected or assigned by the employer or the employer’s representative as being qualified to perform specific duties.

Because the term “qualified” is not itself defined, OSHA would interpret “qualified” in light of operator-qualifications provisions of industry standards such as ANSI B30.2.

ASME B30.2-04: Personnel Competence Persons performing the functions identified in this Volume shall meet the applicable qualifying criteria stated in this Volume and shall, through education, training, experience, skill, and physical fitness, as necessary, be competent and capable to perform the functions as determined by the employer or employer’s representative.

Depending on the industry you are working in, OSHA will have different training requirements laid out. For example construction (29 CFR 1926) has stricter training requirements than general industry (29 CFR 1910). The best way to ensure compliance is through documented training of all lifting, rigging, and material handling activities.

How often should you retrain?

- When roles change or new equipment is introduced.

- If an incident or near-miss occurs.

- When a skill gap is observed.

- Periodically as part of ongoing compliance (no fixed OSHA interval, but ASME standards are updated every 2-5 years. Best practice is every two years and a minimum of every 5 to stay trained on the most up to date practices).

Note: OSHA requires employers to ensure ongoing competency — not just a one-time course.

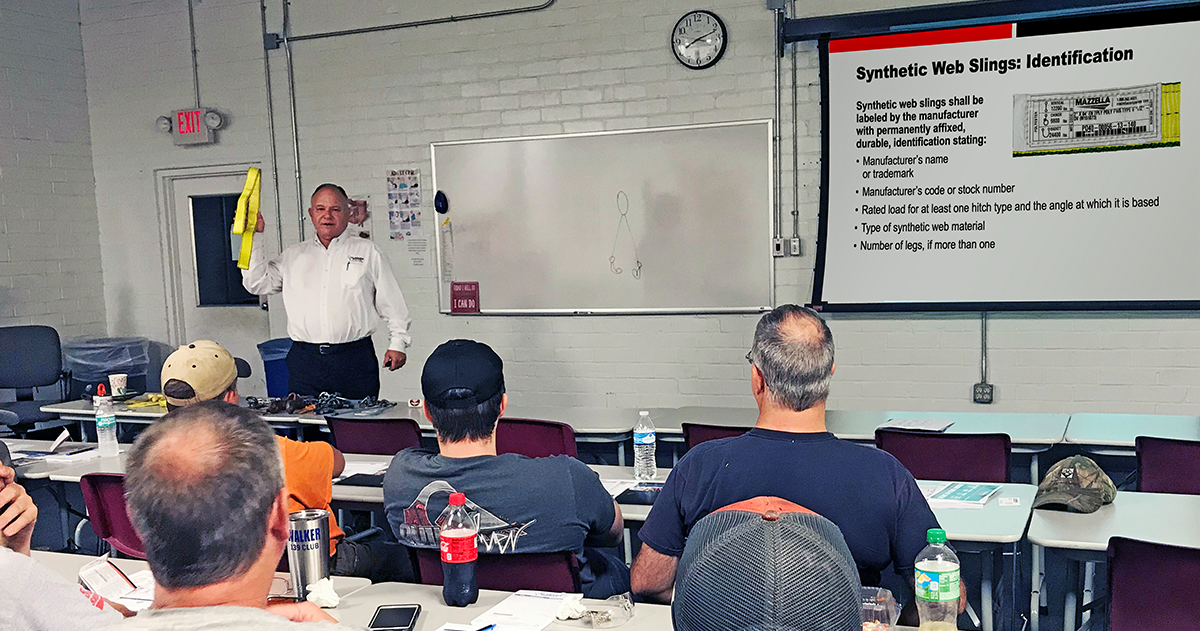

What is included in a Mazzella Training Course?

- OSHA- and ASME-compliant instruction.

- Documentation of completion and competency.

- Student workbook and reference materials.

- Stickers and laminated rigging pocket guides.

- Pens and course supplies.

- Hands-on practice and exams (where applicable).

- Customizable course content for your site, crew, or industry.

What is included in an ITI Training Course?

ITI courses are known for their:

- Advanced-level curriculum (including Lifting Director, Master Rigger, Rigging Engineer).

- In-depth, scenario-based hands-on learning.

- Access to Virtual Reality simulators and eLearning platforms.

- Focus on technical mastery and complex lift planning.

- Accredited certificates and national certifications (e.g., NCCCO).

- Custom programs for highly regulated industries.

ITI is ideal for professionals pursuing high-risk, high-skill roles, while Mazzella excels at onboarding and compliance-level training.

Why should I budget for the right training course?

Cutting corners on training can lead to:

- OSHA violations and fines.

- Serious workplace injuries or fatalities.

- Unqualified operators using dangerous equipment.

- Missed project deadlines due to stop-work orders or equipment damage.

- Increased insurance premiums and liability exposure.

- Inefficient lifts, damaged loads, and equipment failure.

Investing in quality training helps:

- Keep your people safe and confident.

- Ensure compliance with OSHA / ASME requirements.

- Reduce turnover and training gaps.

- Support long-term career development.

Have training rates changed recently?

Training rates are usually reevaluated every two to three years.

Training prices have generally increased due to:

- Higher travel costs and fuel surcharges.

- Greater demand for on-site custom programs.

- Expanded materials (e.g., laminated guides, workbooks, tech-enabled tools).

Do you offer custom pricing or discounts?

Yes — we offer:

- Discounted pricing for refresher courses.

- Volume pricing for large teams or repeat sessions.

- Package rates for multi-session or ongoing training plans.

- Custom quotes based on your site, schedule, and equipment.

What’s the lifetime value of proper training?

Quality training doesn’t just check a compliance box — it prevents costly problems down the line.

Investing in training pays off by:

- Reducing the likelihood of OSHA citations or stop-work orders.

- Preventing injuries that result in downtime, liability, or lost talent.

- Extending the life of equipment by preventing misuse.

- Improving team confidence and reducing operator errors.

- Supporting a culture of safety that attracts and retains good workers.

![OSHA Personnel Designations [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2022/09/resource-download-osha-designations-guide.jpg)