Description

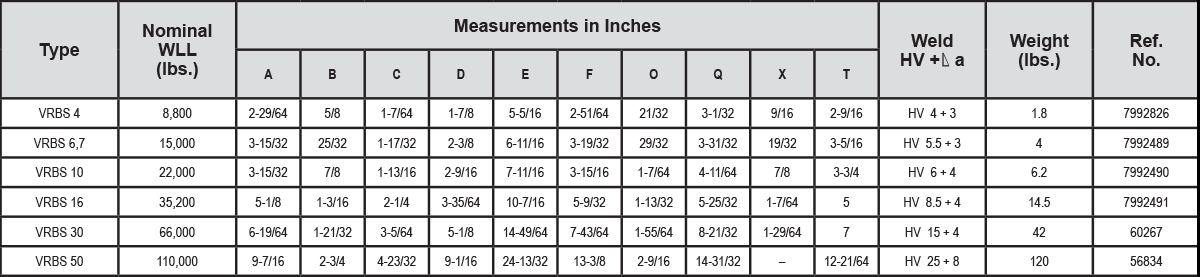

- High dynamic and static strength.

- The welding blocks are forged out of the ideal weldable steel ST52-3N (S355J2+N) and the nominal WLL is embossed.

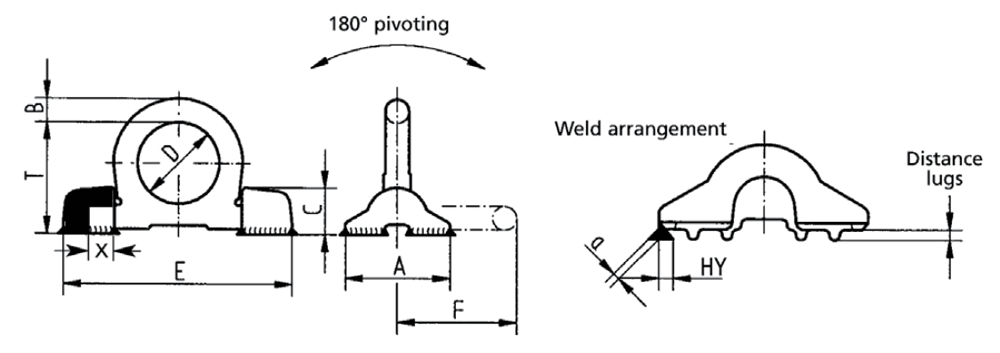

- Patented distance lugs assist in achieving the correct root weld (approx. 3 mm).

- The weld arrangement (continuous HY weld) fulfills the requirements of DIN 18800 i.e. the closed weld avoids corrosion and is thus suitable for outdoor use.

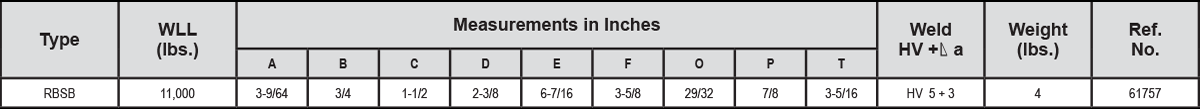

RBSB Application

- The weldable load ring with limit stops is available for EHB containers and machines. The limit stops provide the necessary support for the ring and thus enabling a 45° hook – in inclined position from the work piece.

- Protects the load from severe damage.

Attention: Refer to RUD user welding instructions.

The WLL (Working Load Limit) is listed at the nominal value (worst case scenario) unless otherwise specified.