What Are the Parts of a Wire Rope?

Wire rope consists of three basic components. While few in number, these vary in both complexity and configuration so as to produce ropes for specific purposes or characteristics.

Wire rope consists of three basic components. While few in number, these vary in both complexity and configuration so as to produce ropes for specific purposes or characteristics.

The three basic components of a standard wire rope design are:

- Wires that form the strand

- Multi-wire strands laid helically around a core

- The core

Wire

Wire, for rope, is made in several materials and types: steel, iron, stainless steel, monel and bronze. By far, the most widely used material is high-carbon steel. This is available in a variety of grades each of which has properties related to the basic curve for steel rope wire. Wire rope manufacturers select the wire type that is most appropriate for requirements of the finished product.

Grades of wire rope are referred to as extra improved plow steel (EIP), and double extra improved plow steel (EEIP). (These steel grade names originated at the earliest stages of wire rope development and have been retained as references to the strength of a particular size and grade of rope.) The plow steel strength curve forms the basis for calculating the strength of all steel rope wires; the tensile strength (psi) of any steel wire grade is not constant, it varies with the diameter and is highest in the smallest wires.

The most common finish for steel wire is “bright” or uncoated. Steel wires may also be galvanized, i.e., zinc coated. “Drawn galvanized” wire has the same strength as bright wire, but wire “galvanized at finished size” is usually 10% lower in strength. In certain applications, “tinned” wire is used, but it should be noted that tin provides no sacrificial, i.e., cathodic, protection for the steel as does zinc.

Strands

Strands are made up of two or more wires, laid in any one of many specific geometric arrangements, or in a combination of steel wires with some other materials such as natural or synthetic fibers. It is conceivable that a strand can be made up of any number of wires, or that a rope can have any number of strands.

Core

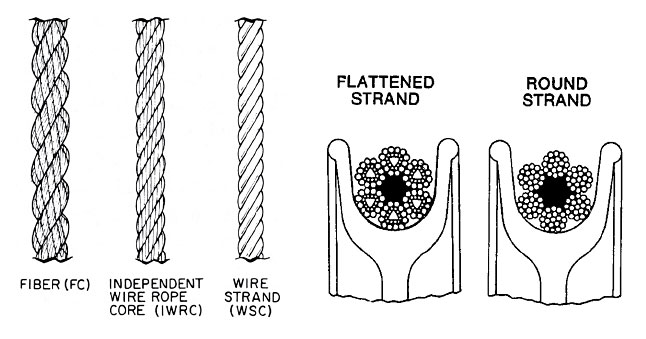

The Core is the foundation of a wire rope; it is made of materials that will provide proper support for the strands under normal bending and loading conditions. Core materials include fibers (hard vegetable or synthetic) or steel. A steel core consists either of a strand or an independent wire rope. The three most commonly used core designations are:

- Fiber core (FC)

- Independent wire rope core (IWRC)

- Wire strand core (WDC)

Catalog descriptions of the various available ropes always include these abbreviations to identify the core type.

The Lay

The word “lay” is used to describe three physical characteristics of wire rope. It is both an engineering term and a descriptive term. Lay describes:

- The direction strands “lay” in the rope—right or left. When you look along a rope, strands of a right Lay make the rope

- The relationship between the direction strands lay in the rope and the direction wires lay in the strands. In a regular lay rope, wires lay opposite the direction of the strand. In a lang lay rope, wires lay in the same direction as strands

- The length along the rope which one strand uses to make one complete spiral around the rope core

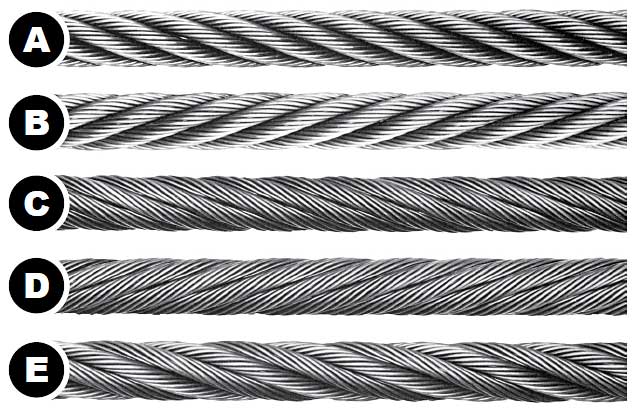

A comparison of typical wire rope lays:

A. Right Regular Lay

B. Left Regular Lay

C. Right Lang Lay

D. Left Lang Lay

E. Right Alternate Lay