Lang lay ropes, when properly recommended, installed, and used, have several advantages over regular lay ropes, but are more often subject to abuse.

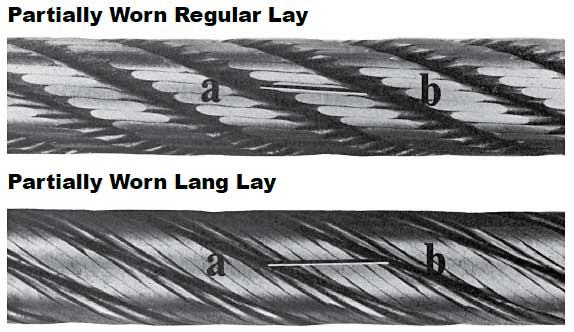

For the same size and construction (ropes having the same wire sizes and lays) lang lay ropes are somewhat more flexible than regular lay and have several times the wearing surface per wire to resist abrasion—as seen in the photos below:

Both ropes shown in the photos have been ground to the same reduction of rope diameter so as to show this comparison of the abraded areas of the wires.

The lang lay ropes, as usually made, are about 15% more flexible than the same construction of regular lay ropes. But, this value will vary depending upon the relation of the strand lay to the rope lay.

Because of the greater wearing surface per wire in the lang lay ropes, there is less wear on the sheave and drum equipment.

On the other hand, very small sheaves or pinching grooves in sheaves are both detrimental to lang lay ropes, the latter frequently causing “bird-caging” of the rope.

Also, lang lay ropes will crush out of shape more readily than regular lay ropes when winding onto small drums under heavy winding tension.

The wires of the regular lay ropes are subjected to higher unit pressure when the rope is passed over sheaves or drum, causing a somewhat heavier transverse pressure within the rope structure. Thus, the “bending” stresses are somewhat higher in the regular lay rope and it is termed “stiffer.”

The mobility of and capacity of shifting among the wires is greater in the lang lay. It is this very feature, combined with the longer exposed length of wires, that causes a misplacement of the wires in the lang lay when bent over sheaves at or near the critical tread diameter, not withstanding the somewhat greater inherent flexibility of the lang lay for normal service.

Swivels should not be used with lang lay ropes except under certain conditions as individually recommended for any particular equipment.

Failure to comply with these foregoing precautions will lead to very uneconomical rope service.

While the total area of surface wear on the rope as a whole is the same for the two types of same construction ropes for a given depth of wear, the wear on the equipment and largely the rope service rendered would favor the lang lay construction.

It is therefore not the total area of worn surface of the rope as a whole, but the nature of such wear that causes longer life to the equipment and to the rope where lang lay ropes can be economically used. To explain this “nature” of wear, we show both on the photo below—lines “a-b,” the line of contact of a moving rope with the sheave; “a-b” is parallel to the direction of rope travel, that is, to the longitudinal axis of the rope.

It will be noted that in the regular lay, the line of contact is axial with one wire; in the lang lay (for the 6 x 19 Seale construction used in this comparison), the line of contact is diagonally across three worn wires.

The shorter exposed length of the worn wires in the regular lay rope causes these wires to spring up, arching radially away from the axis of the rope as in figure below. That causes heavier individual pressure of the wires on the sheave and an earlier fatigue failure of these wires at the “neck” of wear due to local reverse bending when the contact pressure with the sheave depresses this wire. The stiffer the wire (that is, the higher the strength or grade of wire), the more pronounced this arching of the wires at the thinnest worn section or “neck.”