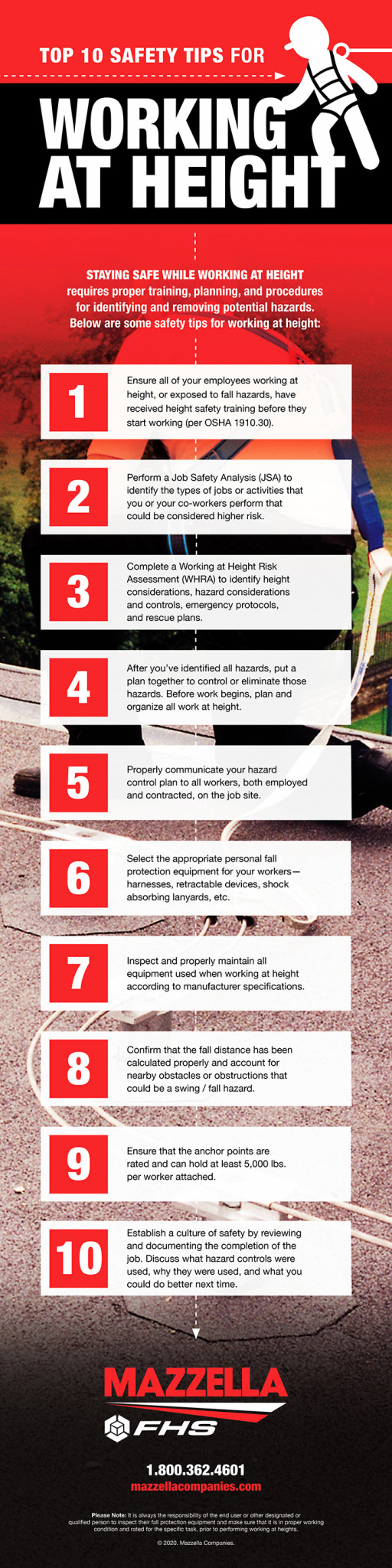

Top 10 Fall Protection Safety Tips for Working at Height

Staying safe while working at height requires proper training, planning, and procedures for identifying and removing potential fall hazards. In this article, we provide tips and best practices for working at height.

Staying safe while working at height requires proper training, planning, and procedures for identifying, controlling, and removing potential hazards. In this article, we’ll cover the top ten fall protection safety tips while working at height.

Keep reading for more information about working at heights. You can download our Top 10 Fall Protection Tips for Working at Height infographic, or download it in an 11×17 poster format to hang in your job site or use as part of a tool box talk.

Top 10 Fall Protection Safety Tips for Working at Heights

>> Click Here to Download Infographic or 11X17 Poster! <<

Summary of Fall Protection Safety Tips:

1. Provide Fall Protection Training for Your Employees

Ensure all of your employees working at height, or exposed to fall hazards, have received fall protection safety training before they start working (per OSHA 1910.30).

Failure to provide fall protection training was # 8 on OSHA’s list of the ten most frequent job site citations.

2. Perform a Job Safety Analysis (JSA)

Perform a Job Safety Analysis (JSA) to identify the types of jobs or activities that you, or your co-workers, perform that could be considered higher risk.

3. Perform a Working at Height Risk Assessment

Complete a Working at Height Risk Assessment (WHRA) to identify height considerations, hazard considerations and controls, emergency protocols, and rescue plans.

4. Establish a Plan to Control or Eliminate Hazards

After you’ve identified all hazards, put a plan together to control or eliminate those hazards. Before work begins, plan and organize all work at height.

5. Communicate Your Plan to ALL Workers on Site

Properly communicate your hazard control plan to all workers—both employed and contracted—on the job site.

6. Select the Appropriate Fall Protection Equipment

Select the appropriate personal fall protection equipment for your workers—harnesses, retractable devices, shock-absorbing lanyards, etc.

7. Inspect Your Fall Protection Equipment Before Use

Inspect and properly maintain all fall protection equipment used when working at height. You should abide by the manufacturer’s specifications for use, inspection, maintenance, and storage for all personal fall protection equipment.

8. Calculate the Total Fall Distance

Confirm that the fall distance has been calculated properly and account for nearby obstacles or obstructions that could pose a swing or fall hazard.

9. Double-Check Anchor Points

Ensure that all anchor points are rated and can hold at least 5,000 lbs. per worker attached.

10. Establish a Culture of Safety

Establish a culture of safety by reviewing and documenting the completion of the job. Discuss what hazard controls were used, why they were used, and what you can do better next time.

Please Note: It is always the responsibility of the end user or other designated or qualified person to inspect their fall protection equipment and make sure that it is in proper working condition and rated for the specific task, prior to performing work at heights.

At Mazzella Companies, we offer all kinds of fall protection and fall arrest solutions, including:

- Temporary and permanent lifeline systems

- Rigid track anchor systems

- Full body harnesses

- Retractables / lanyards

- Energy-absorbing rope

- Ladder climbing systems

- Mobile fall protection systems

We also offer basic, intermediate, and advanced fall protection training courses. Lives are on the line every day when working at height. Many of these fall protection safety tips are covered in more depth in our training courses.

Whether it’s on a job site, or in a manufacturing or industrial facility, it’s critical that your team receives training at height, which is required by OSHA.

Our curriculum is knowledge-based, meaning each student receives comprehensive training and is required to receive an 80% or higher on an exam to successfully complete each course.

If you have any questions about personal fall protection equipment, fall arrest systems, or fall protection training, please contact a Fall Protection Specialist today!

Copyright 2019. Mazzella Companies.