What Is a Rigid Rail Fall Protection System? Different Types & Design

Rigid rail systems are modular in design and can be configured in virtually endless lengths, spans, and fall protection coverage areas. A variety of track styles, mounting styles, and specifications allow you to create a durable and low maintenance fall protection system that will protect one or more workers at height.

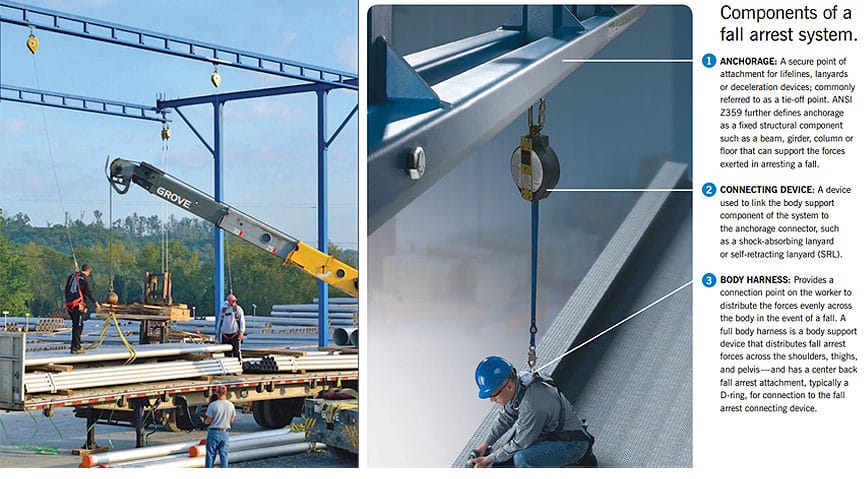

OSHA regulations 1926 and 1910 mandate fall protection for employees working at heights of four feet (general industry), five feet (shipyards), six feet (construction) and eight feet (longshoring operations). When designing a fall protection system, there are many different factors that need to be considered. Understanding the ABCs of Fall Protection is a good place to start:

- Anchor

- Body Device

- Connecting Device

But, you should also be aware that there are engineered solutions available that can be designed specifically for your job site, facility, or application. Rigid rail fall protection systems are some of the most complete and innovative fall arrest systems available—for both indoor and outdoor applications.

Rigid rail systems are modular in design and can be configured in virtually endless lengths, spans, and fall protection coverage areas—ranging from large to small. A variety of track styles, mounting styles, and specifications allow you to create a durable and low maintenance fall protection system that will protect one or multiple workers at height.

In this article, we’ll discuss the following:

- The definition of a rigid rail fall protection system

- The components of a rigid rail fall protection system

- The different types of permanent rigid rail solutions

- The different types of portable rigid rail solutions

Whether you need a standard off-the-shelf kit, or a fully customized solution, there’s a rigid rail fall protection solution available to protect your workers at height.

What Is a Rigid Rail Fall Protection System?

A rigid rail fall protection system is a type of fall arrest system that is comprised of:

- Anchor – An anchor trolley that runs along an engineered I-beam, rail, or an enclosed track system

- Body Device – Full body harness worn by the user

- Connecting Device – Shock absorbing or self-retracting lanyard connected to the anchor trolley and the body harness of a worker at height

When a self-retracting lanyard is connected to a body harness and an anchor trolley, a worker at height has a continuous and secure connection to the rigid fall arrest system. This configuration allows the worker to safely travel the full length or span of the track system when performing their job duties. Remember to always inspect your personal fall protection equipment!

Rigid track fall arrest systems are commonly found in general industry, mills and foundries, and manufacturing facilities. They’re also popular in facilities that assemble or service high-profile vehicles, including:

- Die handling / automotive stamping

- Aircraft and aerospace

- Boats, ships, and barges

- Trains and railcars

- Trucks and trailers

- Buses and RVs

- Other commercial or industrial equipment

What are the Advantages of a Rigid Rail Fall Protection System?

Rigid rail fall protection systems are ideal for both indoor and outdoor applications with minimal fall clearance. They can be permanently mounted to existing structures or suspended from floor or wall mounted supports. There are also a variety of applications that can utilize a portable rigid rail design for applications that don’t have overhead anchor points, or for applications where the workers are not consistently confined to one specific work area.

They offer many advantages over traditional wire-based lifeline systems, including:

- Fall clearance – a rigid rail system can be used in low-headroom applications because it will stop the fall in a shorter distance than a traditional wire rope system can

- Less sag – a wire rope suspended between supports will always carry a certain amount of sag and deflection in the rope under fall conditions

- Reduction of secondary fall injuries – in the event of a fall, the sag/deflection of a wire-based system will cause the trolley to slide towards the center of the supports in order to center itself. This can cause the worker to swing and collide with nearby obstacles.

- Safe for multi-user environments – a rigid track system can be designed to accommodate multiple users on one system—including user bypass capability

- No permanent deformation – these types of systems are comprised of components that are longer-lasting and lower maintenance. In the event of a fall, there is minimal inspection and maintenance needed to return the system to service.

In a rigid rail application, the force of a fall is primarily vertical against the anchor point. The combination of vertical force, no wire deflection, and almost instant arrest with a self-retracting device means minimal forces will be exerted on the fallen worker.

What are the Disadvantages of a Rigid Rail Fall Protection System?

Cost is probably the most significant disadvantage of a rigid fall arrest system. If existing I-beams can’t be utilized, then a track or rail system needs to be fabricated and installed. In some cases, the installation of additional structural steel may be required to support the weight of the tracks plus the weight of the calculated fall arrest load.

Also, a rigid rail system can be more of a permanent fall protection solution. In industries like construction or roofing, a permanent solution is not ideal for workers who move from job site to job site. In those instances, a flexible wire-style lifeline system can be most effective and economical.

What are the Components of a Rigid Rail Fall Protection System?

Anchor Trolley

An anchorage trolley travels on wheels inside the enclosed rigid track system. The wheels can be tapered slightly to center the trolley and keep it properly aligned within the track for smooth and effortless movement and reduce wear. The wheels are made of durable material and commonly feature sealed bearings to prevent dust, dirt, and grime from restricting the motion of the trolley.

Many types of trolleys have a swiveling connector to attach the lanyard to. This design can swivel 360° preventing the lanyard strap from getting twisted and tangled. The connector on the trolley may also pivot slightly to combat potential side loading stress on the trolley. The pivot and twist allow the worker to move freely without restriction and prevents excessive wear to the internal components.

Some trolleys feature a load-activated brake that will stop the trolley in its place on the track in the event of a fall. When a fall occurs, the combination of the worker’s weight and the force of the fall engages contact between the trolley and the track. This prevents additional lateral motion of the trolley and reduces the risk of the worker swinging and colliding with other nearby obstacles. This feature also increases the possibility of the worker being able to self-rescue in the event of a fall.

Rigid Track or Rail

A rigid rail system utilizes enclosed rail or tracks that are engineered for easy movement of the trolley across the span of the system. This rail or track can be mounted off of the anchorage structure, walls, or flooring material, and can be configured with bends or curves to accommodate rooflines or existing structure and equipment.

An enclosed track or rail design allows the trolleys to continue to move along the track with minimal resistance, while protecting the wheels and providing optimal trolley alignment. These systems are self-cleaning so there is virtually no maintenance in terms of lubricating or cleaning the track system.

For outdoor applications where components may be exposed to the elements, the beams or track can be made from stainless steel, galvanized material, or aluminum material for corrosion resistance.

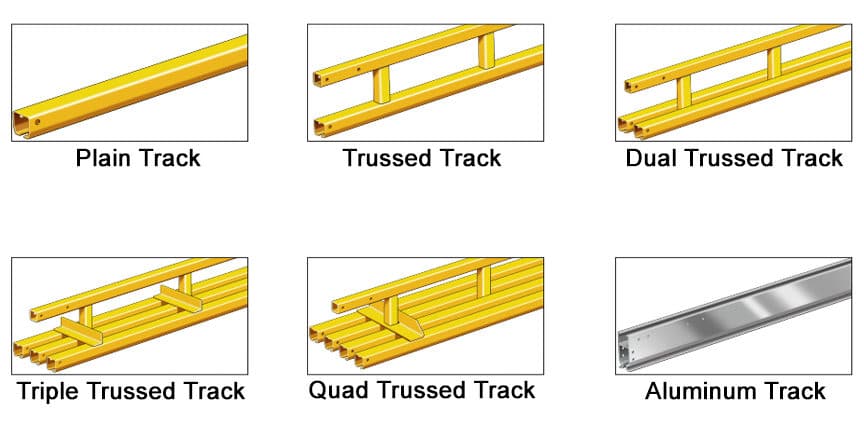

Different types of Rigid Track:

- Enclosed Plain Track – Plain track is not reinforced like trussed track, so it’s used where you’re able to utilize close support centers. Plain track is cost-effective, and offers the most headroom while keeping installation requirements to a minimum. Plain track can only be utilized for one worker on the system and cannot achieve the same span as reinforced trussed track systems.

- Enclosed Trussed Track – Trussed track is much sturdier than plain enclosed truck, and the trussed steel allows for increased spans with fewer supports needed—reducing hardware and installation time. Trussed track reduces stress on structures and can also accommodate more than one worker at a time.

- Dual Trussed Truck – Same as trussed track, but can accommodate two or more workers at a time

- Triple Trussed Track – Another variation of trussed track where three workers can be connected and pass one another

- Quad Trussed Track – Another variation of trussed track where four or more workers can be connected and pass one another

- Aluminum Extruded Track – Extruded from high-strength aluminum alloy. Used in applications where the weight of the system is a major consideration, or where corrosion may be a factor. Aluminum track is virtually maintenance free and suitable for clean rooms, refrigeration areas, and other controlled environments.

Track Hardware and Supports

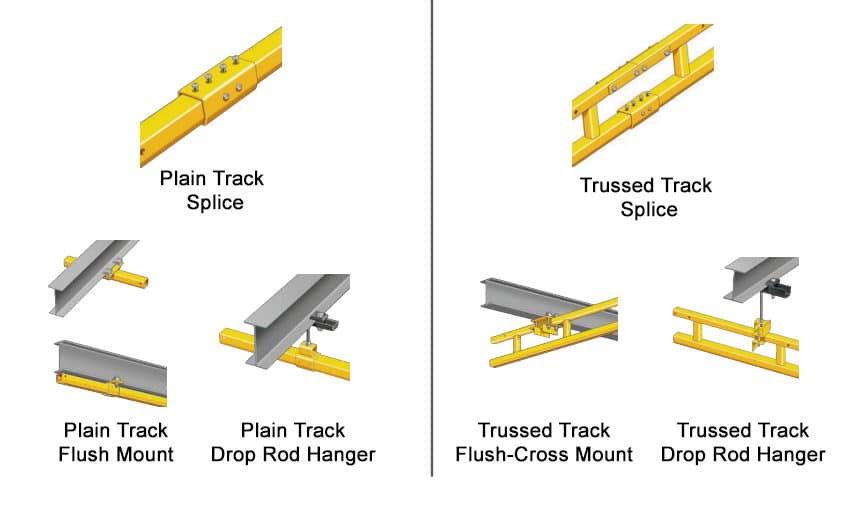

Track Splice:

- Plain track: Precisely align and connect track sections using two vertical and four horizontal adjustment screws

- Trussed truck: Two pieces. Same as plain, but second piece provided with a plate for the truss

Hanger Assemblies:

- Flush Mount Hangers:

- Plain track: Mount either parallel or perpendicular to ceiling beams

- Trussed track: Used to mount a truss track perpendicular to the existing beam

- Drop Rod Hangers:

- Plain track: Features a support bracket, 12” drop rod, and adjustable roof beam clamp. Sway bracing is required when using a drop rod hanger.

- Trussed track: Features a support bracket, 12” drop rod, and adjustable roof beam clamp. Sway bracing is required when using a drop rod hanger.

- Sloped Hangers: Can accommodate roof slopes of up to 14° when using drop rods. Drop rod hangers do require additional sway bracing.

Types of Permanent Rigid Rail Fall Arrest Systems

In this section, we’ll discuss the permanent types of rigid rail fall arrest systems that exist. Each of these types of systems utilizes one of the following support methods:

- Overhead / structural ceiling mounts

- Freestanding support with concrete foundation

- Existing building or wall support columns

When selecting the best type of permanent rigid rail fall arrest system, consider the following:

- Available floor space

- Existing ceiling, building, or wall supports

- Existing obstructions

- Size of work area

- Scope of fall protection coverage required

Ceiling Mounted Monorail Systems

Ceiling mounted monorail systems utilize the existing support structures and do not require support columns, so floor space is unaffected by the system once it is installed. These types of systems are excellent for applications with tall ceilings. The main advantage of this type of system is it allows for workers to greater utilize the floor space for workstations, work cells, storage, or production.

Ceiling mounted monorail fall arrest systems are easy to customize and easy to install using a variety of different bracket options.

Commonly used for:

- Production and warehouse facilities

- Vehicle loading / unloading / maintenance

- Industrial cleaning and maintenance

Features and benefits:

- Used in facilities or warehouses with tall ceilings and/or tight bays with limited floor space

- Easy installation and mounts to existing support structure

- Easily accommodates long spans of fall protection coverage

- Single or multi-user systems with or without bypass

- Available as standard kits or in custom designs for specific applications

Inverted “L” Freestanding Monorail Systems

Inverted “L” monorail systems are a freestanding type of fall arrest system that utilizes concrete foundations to cover long spans of fall protection coverage. A freestanding steel column and horizontal arm support the rigid rail track at heights upwards of 25’ and can be designed as standard system kits with customized lengths, heights, and arm reach.

The major benefit of an Inverted “L” monorail system is that these types of monorail fall arrest systems are intended for applications where there are no existing support structures by utilizing a concrete foundation.

Commonly used for:

- Transportation industries to work on rail cars, trucks and trailers

- Outdoor environments

- Workers who need to access the top of a structure

Features and benefits:

- Used in facilities where existing support structures are not available

- Quick and easy field installation

- Easily accommodates long spans of fall protection coverage

- Single or multi-user systems with or without bypass

- Available in standard kits or custom designs for specific applications

T-Frame Freestanding Monorail System

T-frame monorail systems are a freestanding type of fall arrest system that features two parallel fall arrest monorails supported by a single center row of columns. This configuration utilizes a concrete foundation and a T-Frame support beam configuration.

The major benefit of a T-Frame monorail system is that it allows for workers to perform maintenance or service two vehicles at once—without the need for additional support.

Commonly used for:

- Outdoor environments for transportation

- Servicing two vehicles with one system

Features and benefits:

- Provides two monorail systems with a single row of support columns

- Used in applications where there are no existing support structures

- Quick and easy field installation

- Easily accommodates long spans of fall protection coverage

- System can support one to four workers per side

Inverted “U” Freestanding Monorail System

Inverted “U” monorail systems are a freestanding type of fall arrest system that features two steel columns connected at the top by a support beam, with a single monorail suspended along the beam. The Inverted “U” systems require a concrete foundation, but are typically smaller foundations than the ones found on Inverted “L” and Inverted “T” monorail systems.

The main advantage of using an Inverted “U” monorail system is that the monorail can be centered or offset along the support beams to work around existing obstructions.

Commonly used for:

- Maintenance or inspections on transportation equipment or machinery

- Any industry where floor mounted systems are necessary

Features and benefits:

- Monorail can be centered or offset to position the worker and trolley around existing obstructions

- Used in applications where there are no existing support structures

- Quick and easy field installation

- Easily accommodates long spans of fall protection coverage

- System can accommodate one to four workers per side with bypass

Traveling Bridge Systems

A rigid track bridge system consists of two parallel runways and a traveling bridge that follows the worker—remaining directly overhead. The worker is able to travel up and down the runway, as well as across the width of the bridge for full 360° unencumbered movement.

Traveling bridge systems can be either ceiling mounted or freestanding in their design. A ceiling mounted bridge system is mounted either perpendicular or parallel to the structural ceiling support beams. Drop rod hangers can be used to avoid overhead obstructions or obstacles. A freestanding system utilizes support columns and headers and can be easily moved if a work area or building layout changes.

The runways on these types of systems can accommodate multiple bridges to allow multiple workers to move and work independently. Bridge systems are ideal for facilities where coverage of large work areas is required.

Commonly used for:

- Aircraft hangars / aircraft production facilities

- Large production and processing plants

- Transportation vehicle maintenance facilities

- Industrial applications

Features and benefits:

- Can be either ceiling mounted or freestanding in design

- Trolley follows worker in any direction (360° of coverage)

- Attachment point stays directly over the worker to minimize swing fall hazards

- Multiple bridges for multi-user systems can be utilized on the same structure

Fold Away Systems

The concept of a fold away system is simple and self-explanatory—these work great in a facility that needs a fall arrest solution for workers at height, but folds up and out of the way when not in use. These fold away systems are the perfect solution when fall protection is required in or near the bay of an overhead crane, when floor space is limited, or when fall protection requirements are infrequent.

When the arms are fully extended and locked into place, a fold away system provides a fixed path of rigid rail for one or multiple workers to work at height. When not in use, the track and arms can be conveniently folded back against the support columns and out of the way. Fold away systems can be freestanding, column mounted, or wall mounted in their design.

Commonly used for:

- Railroad or truck maintenance facilities

- Food processing plants or manufacturing facilities where workers need fall protection under overhead cranes

- Facilities where floor space is an issue or maintenance occurs in narrow bays with no workable ceilings

- Facilities where infrequent fall protection is necessary

Features and benefits:

- Maintain productivity without compromising safety—deploy when fall protection is necessary and neatly fold in and out of the way when not in use

- Motorized arm rotation is available

- Perfect solution for applications where overhead cranes are operating above a work cell

- Can be freestanding, column mounted, or wall mounted in design

- Single or multi-user systems with bypass

Swing Arm Systems

A swing arm system provides circular or semi-circular fall protection coverage in a design that is compact and has a limited footprint. Swing arm systems are ideal for small to medium-sized work areas and can be moved out of the way when not in use. Both the arm and the trolley follow the worker while in use and keep the trolley positioned directly over the worker to limit swing fall hazards.

A freestanding swing arm system is foundation mounted and can provide a full 360° of fall protection coverage.

A column or wall mounted design provides 180° of arm rotation and can be mounted to existing building support columns or to wall columns.

Commonly used for:

- Small to medium-sized work areas

- Applications where fall protection systems and overhead cranes share the same space

Features and Benefits:

- Cost-effective and compact fall protection solution in a circular or semi-circular coverage area

- Can be folded or moved out of the way when not in use

- Can be freestanding, column mounted, or wall mounted in design

- Tracks can accommodate single or multiple workers with bypass

Post Suspension Systems

Post suspension systems provide an independent and permanent fall protection solution in a space where obstacles exist or where numerous support columns can’t be accommodated. The design includes a single post or multiple post configuration, and can accommodate one track or two tracks (one on each side of the post). The simple design can accommodate virtually any height and is ideal for areas that require long spans of fall protection.

Commonly used for:

- Tank car applications

- Heavy-duty truck securing

- Tarping areas

- Vehicle loading / unloading and maintenance facilities

Features and benefits:

- System requires fewer foundations and uses less steel over conventional systems for a significant cost-savings

- Can be engineered with single or twin bays

- Can be configured with single, dual, or multiple tracks to accommodate multiple workers

- Can be installed in areas of minimal floor space or where multiple obstructions exist

Types of Portable Rigid Rail Fall Arrest Systems

In some applications, a permanent fall arrest solution may not be ideal. In these instances, you may want a portable fall protection system that you’re able to move freely between workstations, maintenance bays, or production areas. Below are some examples of portable rigid rail fall protection solutions.

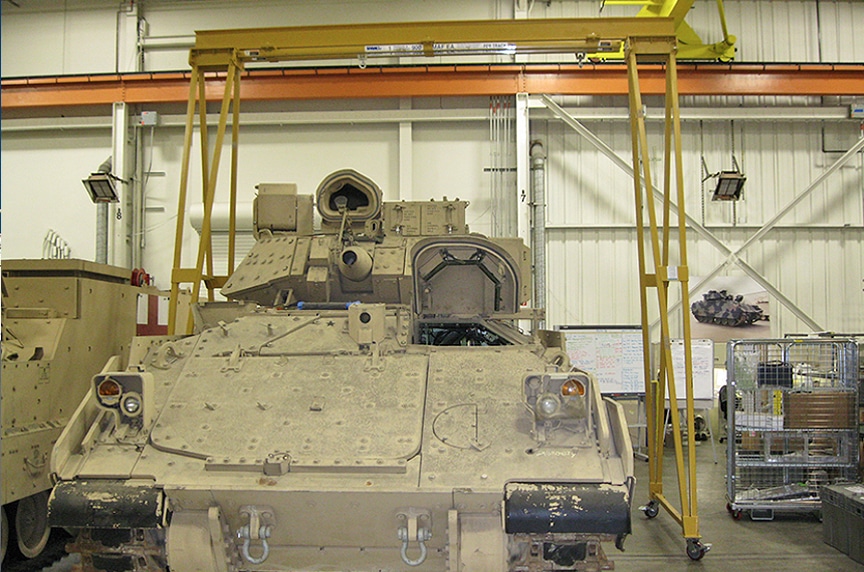

Gantry / A-Frame Systems

These types of systems are similar to a portable gantry crane system in that they simply roll into position and lock into place. The mobility saves space, time, and money by eliminating the need to install a permanent fall protection solution. Gantry / A-Frame systems are available in fixed or adjustable heights for ultimate versatility.

A variety of different casters are available, depending on the operating environment, for easy mobility and positioning.

Commonly used for:

- Maintenance and manufacturing applications

- Mining and excavating

Wheeled or Skidded Systems

The design of a wheeled or skidded fall protection system consists of outrigger arms from two support columns attached to a standard skid-mounted base or a steerable wheeled chassis. A skidded system can be maneuvered into place with the help of a forklift and a wheeled configuration can be towed and steered into place using a heavy-duty pickup truck.

Manual leveling jack plates are provided to allow the entire 15,000 lbs. system to be leveled in any environment.

Commonly used for:

- Outdoor applications

- Truck loading

- Manufacturing and maintenance of large vehicles or aircraft

Wrapping it Up

A rigid rail fall protection system helps reduce workplace risks and protects your workers from hazards. When designing a rigid rail fall arrest system, it’s important to consider the following criteria to get a system that accommodates the needs of your facility and your workers:

- Rail or Track Style: Can you utilize plain track, or will trussed track be necessary? Will the system need to accommodate more than one worker? Will the workers need to be able to pass each other freely without disconnecting?

- Mounting Style: Ceiling mounted, freestanding (concrete foundation), column mounted, or wall mounted?

- Coverage Area: Do your workers work in a fixed path, or do they need a broader 360° or circular coverage area?

- Working Conditions: Are your workers working in a confined bay or space? Is this an outdoor or indoor application? Are there overhead cranes operating nearby?

- Permanent or Portable: Will this system be a permanent fixture in your facility, or will you need to be able to move it freely between workstations or production areas?

- Single or Multiple Operation: Are workers working on one or multiple pieces of equipment at a time?

At Mazzella, we carry a full line of fall protection equipment, including lifelines, harnesses, anchor points, rope grabs, and more.

We also work with our customers on custom-engineered fall protection and fall arrest solutions. We have relationships with all of the major vendors and suppliers in the industry and can work with you to design a fall protection system that meets the requirements of your project and your budget. All of our engineering and installation is done in compliance with OSHA and ANSI design requirements.

If you’re interested in learning how we can help you stay in compliance with industry fall protection standards, or want to bring us in for OSHA-mandated fall protection training, please contact us to schedule a consultation.

Images of rigid rail and rigid track fall protection systems courtesy of Rigid Lifelines, Inc. and Gorbel, Inc.

Copyright 2019. Mazzella Companies.