6 Ways to Preserve Knowledge in the Lifting Industry

With experienced lifting professionals about to retire from the workforce, find out how to capture their knowledge and educate the next generation at your organization.

In many industries and companies across the country, there’s a concerning trend: millions of workers with decades of experience are about to retire. And no one is there to fill their position or learn from them.

The lifting and rigging industry is not immune to this phenomenon. When talking to industry experts, they routinely express concerns of “lost knowledge” in the industry.

Soon, those experienced men and women who’ve perfected their craft over the years will retire. Who will teach the younger generations about the best way to hand splice wire rope? Who can pass on tips on sewing synthetic lifting slings? Who will pass that “tribal knowledge” to the next generation?

If action isn’t taken, critical industry knowledge and technical expertise will be lost, and our industry—and world—will be worse off.

However, there are many steps your organization can take to prevent this from happening. Spearheaded by the Lifting Equipment Engineers Association (LEAA), we now have Global Lifting Awareness Day—a day to showcase the great work our industry does, the challenges we face, and the manufacturers, suppliers, and end users who work in lifting every day.

For this year’s GLAD theme, “Lifting Careers, Building Futures,” our article will list six ways your company can preserve and pass on those learned experiences to the next generation.

- What Is Tribal Knowledge and Institutional Knowledge?

- What are Some Examples of Tribal Knowledge in Lifting and Rigging?

- How Can Your Organization Preserve Lifting Knowledge?

- Why Is Lifting Knowledge Not Getting Passed Down?

- Final Thoughts

What Is Tribal Knowledge and Institutional Knowledge?

Tribal knowledge is a term used to describe the unwritten / undocumented rules, knowledge, and expertise within a company that is only known to people through word-of-mouth. Tribal knowledge usually focuses on best practices and processes. It’s the lessons learned from doing a project or task hundreds—even thousands—of times. They are not the lessons you find in a manual. Some authors and researchers have referred to tribal knowledge as the “collective wisdom” of an organization.

Institutional knowledge refers the accumulated knowledge of an organization, both documented and undocumented information. Companies who have processes and share institutional knowledge can reduce the gap between experienced employees and new team members, improving the organization’s overall performance.

What are Some Examples of Tribal Knowledge in Lifting and Rigging?

It would be hard to find a career with more tribal knowledge than lifting and rigging. Tribal knowledge could include information on the best quality wire ropes for a particular project. It could be phrases to help with proper wire rope clip installation, like “never saddle a dead horse.”

Even the rigging slang used in the industry is a great example of tribal knowledge, where a single tool can have dozens of nicknames, passed down from one generation to the next.

Tribal knowledge, especially in material handling, is not just about the physical part of the job, but it also covers thought processes and troubleshooting complex problems. However, the problem is that these valuable tips are not written down.

According to our in-house training experts, during a wire rope technician training course, 95% of the training will be on the job, but very little of the lessons taught in the field are written down.

How Can Your Organization Preserve Lifting Knowledge?

Start a Mentorship Program

Starting an in-house mentorship program is one of the most powerful tools for transferring knowledge. Pairing less-experienced employees with seasoned professionals creates a two-way relationship that benefits both parties. New team members gain helpful tips and insights to speed up career growth opportunities, while experienced workers find purpose and recognition in the twilight years of their career.

Structured mentorship programs can include job shadowing, scheduled check-ins, and project-based learning. Over time, this creates a culture where knowledge is not only retained, but also actively passed on.

Mentorship programs also connect succession planning with day-to-day learning and embed expertise across teams.

Document Processes, and Update Them

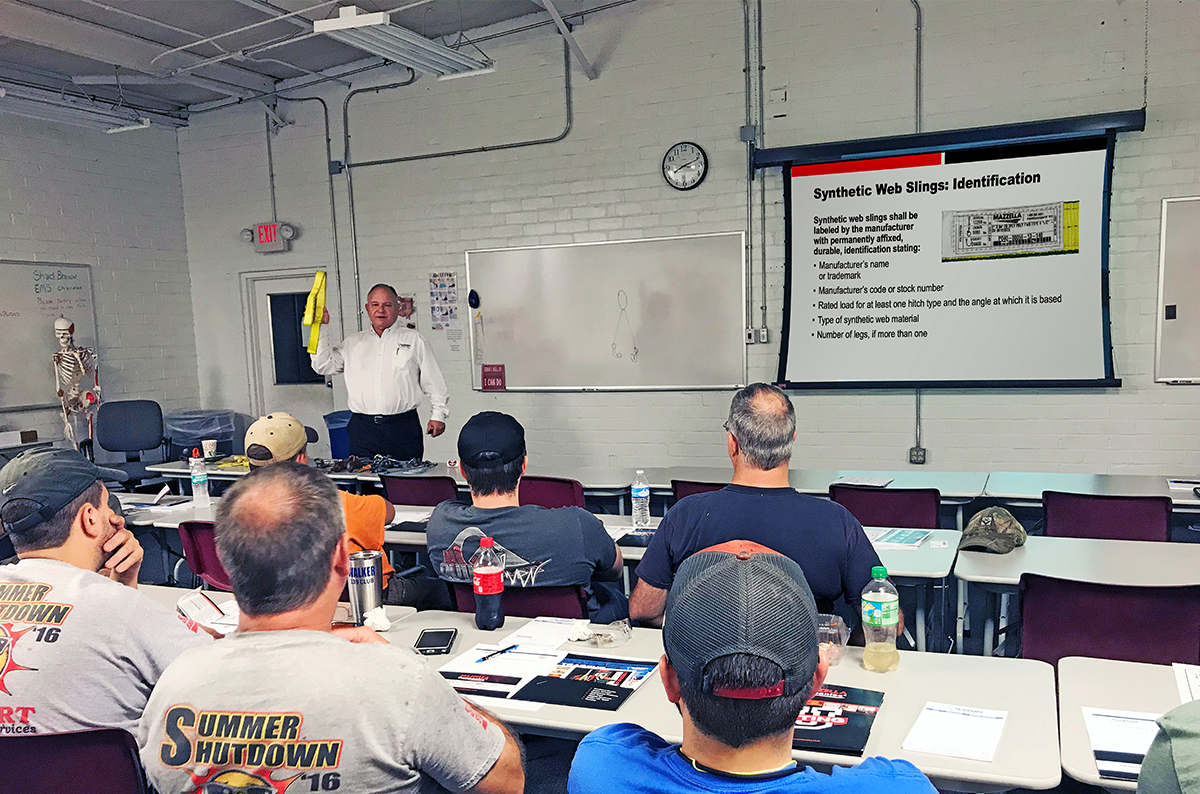

On top of your mentorship programs, document the processes your experienced workers are doing. Whether it’s a full-length training video or a cheat sheet / flyer posted in the breakroom, documenting these processes is crucial to preserving generational knowledge.

And with OSHA, ASME, and ANSI regulations changing constantly, it’s always important to review existing processes and update them to ensure workers are complying with current standards.

Make Your Processes and Training Material Easy to Find

If you have processes in place, but workers can’t find them, they don’t exist. Put effort and resources into making your training content easy for workers toconsume.

Consider what type of work they’re doing and how they process information. Are they an inside sales representative or accountant who spend a lot of time online? Upload their training document to an online portal. If the worker is out in the field or shop all day, consider creating guides and “cheat sheets” that they can easily glance at while out in the field.

If you have old DVDs, VHS tapes, or catalogues laying around your office, convert them in a digital format and store them in the cloud. As our experts put it, the lifting industry was built through catalogues. These old documents are filled with knowledge, but many will just collect dust in a supply closet. These resources are a gold mine for new workers.

Identify Experts in Your Organization Well Before They Retire

You don’t have to wait until someone gives their retirement notice to document their expertise. These experts holding the tribal knowledge can come from any department in your company and be in any position. The expert in question can be a rigger in your shop with 30 plus years of experience who has mastered the art of splicing flemish eye wire rope slings and synthetic ropes. It can also be the experienced salespeople who have built incredible relationships with clients over the years.

Find those workers in your organization who others routinely go to for help and advice. Engage them now. Ask questions, record their insights, and involve them in training initiatives.

Remember that the experts at your organization are not professional trainers. There’s a difference between being great at your craft and disseminating information for other people to learn. Work with your experts to:

- Create training material

- Plan classes and create schedules that work for everyone

- Juggle their daily tasks with training responsibilities

It’s also important to make this an enjoyable experience for the seasoned employee. Not everyone likes to be on camera. Ask them what they’re comfortable with, and make the conversations / lessons organic.

Have a Succession Plan In Place

One of the most important yet often overlooked strategies is succession planning. Succession planning is about taking a holistic view of your organization’s future staffing needs, which include:

- Identifying employees who are retiring soon

- Developing individuals to take over their responsibilities when they leave

- Capturing the retiring employee’s knowledge before they depart the organization

Don’t wait until employees submit retirement notices. Proactively assess your workforce and identify those who are likely to leave soon. Then, start transferring their knowledge well in advance.

Start a Rotational Program

Rotational programs are professional development programs where new hires rotate through different roles or departments within a company. Rotational programs give new-to-career workers, including recent high school and college graduates, a chance to:

- Explore career opportunities in lifting and rigging

- Get a holistic view of how a material handling companies operate

- Improve their career prospects

For example, Mazzella’s RISE (Rotational Immersion and Skill Building Experience) Program gives participants a chance to work in the Finance, Inside Sales, Operations, and Supply Chain departments.

With Gen Z projected to make up 30% of the U.S. workforce by 2030, setting up a rotational program is a great way for lifting organizations to not only attract younger talent but also connect them with seasoned employees in multiple departments.

Pairing a rotational program with documented training material (with information taken from in-house experts) is a solid strategy for preserving institutional knowledge.

As we discussed in last year’s Global Lifting Awareness Day article, many people (especially younger folks) outside of the lifting industry only see the tip of the iceberg regarding career opportunities. Material handling companies are not only looking for Riggers and Crane Operators, but they are also looking for the next generation of Accountants, Engineers, Marketers, Human Resource Specialists, IT professionals, Safety Inspectors, and Trainers. Rotational programs are a chance for you to spotlight those opportunities.

Why Is Lifting Knowledge Not Getting Passed Down?

Many companies in our industry haven’t faced the issue of lost knowledge before. These experts in our organization have become so reliable and engrained in the company that the thought of them eventually leaving is not considered.

Chaos ensues when these kinds of employees leave, and that’s because organizations don’t have proper succession plans and training protocols in place. Many companies may not see the value of investing time and resources into building training or rotational programs.

Final Thoughts

The lifting industry is built on experience, precision, and safety—all of which rely on deep operational knowledge. However, without investing the proper resources and time into mentorship and rotational programs, succession plans, and documenting processes, our industry could soon lose decades of expertise.

Whether it’s in the white collar or blue collar side of the industry, we have work to do to preserve those decades of knowledge that have been passed down through generations. It’s not too late to act. Bring up these topics in your next meeting, start identifying those experts and create a plan to capture their knowledge.

At Mazzella, we believe people from all walks of life have a place in this wonderful and important industry, and we hope this article gave you tips on how to preserve and pass on those learned experiences to the next generation.

Visit Inside Mazzella Companies to learn more about our company culture and career opportunities in the lifting industry. Also make sure to check out LEEA’s website to learn more about Global Lifting Awareness Day.

Copyright 2025. Mazzella Companies.