A Look at CM’s New BatteryStar™ Electric Chain Hoist

Investing in a battery-operated hoist is also an investment in your workers’ safety. Columbus McKinnon's new BatteryStar™ Electric Chain Hoist is the first battery-powered hoist from a US-based manufacturer. The BatteryStar™ offers riggers the ergonomics and ease of use of an electric hoist combined with the portability of a manual hand chain hoist. Read our article to learn more about the BatteryStar's best applications, benefits, safety features, and inspection criteria.

Is it worth it to invest in a battery-operated chain hoist?

While manual and powered chain hoists have been a staple at job sites for decades, there are multiple applications where a battery-operated system could improve your processes.

Do you need the ergonomics and ease of use of an electric hoist combined with the portability of a manual hand chain hoist? Thankfully, our partners at Columbus McKinnon have just released the BatteryStar™ Hoist, the first battery-powered hoist from a US-based manufacturer.

The BatteryStar ™ gives workers in multiple industries a convenient and portable tool to speed up efficiencies and reduce manual labor.

We understand that you may be hesitant to purchase a brand-new product. You may be comfortable with the hoist you already have. You may have trouble convincing your manager to invest in more equipment for your job site. Our article, with the help of our partners at Columbus McKinnon, will break down everything you need to know about the BatteryStar, including:

What is the BatteryStar™ Hoist?

The BatteryStar ™ Electric Chain Hoist is Columbus McKinnon’s first battery-powered hoist. Manufactured at their plant in Damascus, Virginia, it is also the first US-based hoist manufacturer to put a battery-operated hoist on the market.

With a 1-tonne lifting capacity, this battery-powered system allows riggers and operators to lift or lower heavy loads without having to worry about pesky wires or strain from manual labor. It weighs around 45 lbs., making it easy for workers to carry around a job site.

The standard BatteryStar offering includes:

- A standard chain bag

- A remote control

- Type T per EN818-7 lifting chain

CM™ manufactures all their hoist chains, and they have a lift configurable ranging from 5-60 “.

Like other battery-powered tools, it’s easy to replace and charge the batteries as you work using sets of spares. But, if it runs out of power, you can manually lower the load with a power drill. Plus, having a remote removes worry about pendant cable length and allows you to use the hoist from any height up to 60″.

What Is the Relationship Between Columbus McKinnon and Milwaukee Tool®?

The strong relationship between Columbus McKinnon and Milwaukee is shown in their collaboration on the BatteryStar™ Hoist. Columbus McKinnon designed and manufactured the BatteryStar™ while working with Milwaukee to integrate their battery into it.

You will notice that the hoist comes in two colors: the black one has the CM™ logo, while the red model will have the Milwaukee Tool® logo.

Outside of branding, the only major difference between the two models is the Columbus McKinnon unit will be available up to 60′, while the Milwaukee unit will stop at 20′. The swivel hoist is also not available on the Milwaukee model.

Anyone who purchases the BatteryStar™ can connect it to Milwaukee Tools’ ONE-KEY™ app, which allows users to connect the hoist for:

- Easier tracking and asset management

- Easy access to important equipment information from your computer or smartphone

- Setting reminders on upcoming hoist inspections

- Storage of previous inspection records and other important documents

- Milwaukee Battery

The BatteryStar™ is powered with the M18™ REDLITHIUM™ Battery from Milwaukee Tool®, which is also compatible with over 250 Milwaukee Tool® products. There’s a high chance you already have cordless Milwaukee tools on your job site, battery at your facility or job site.

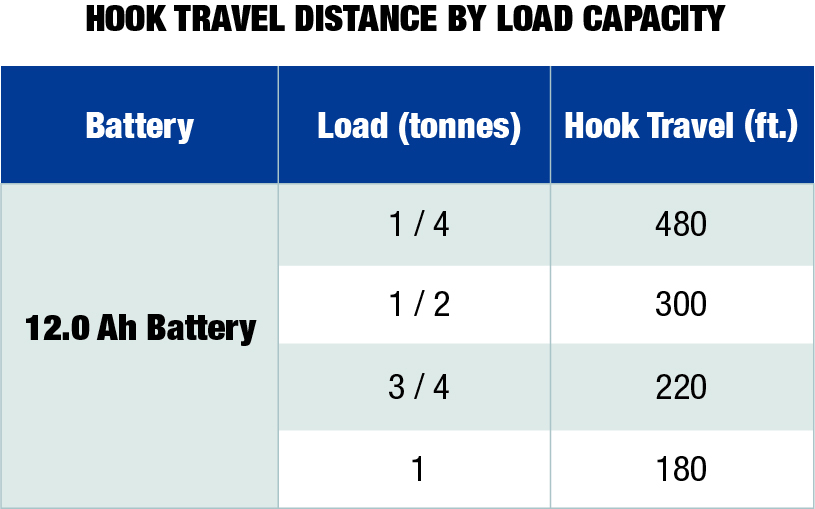

The battery’s lifespan depends entirely on the weight of your load. The battery’s runtime will depend greatly on the weight of your load, among other factors.

The BatteryStar™ was designed to last hours without charging in typical 500 lbs. applications with a new battery. If you’re lifting loads closer to 1-tonne, you can expect the battery to drain quicker. If you’re lifting loads closer to 1-tonne, you can expect the battery to drain quicker.

What are the BatteryStar’s Best Applications?

The BatteryStar™ will thrive in any application where high efficiency and power is needed, but no power source is readily available. Consequently, they can be used in various industries and applications. Some of them include:

- Construction and excavation companies

- Low-volume fabrication / production / assembly lines

- Mechanics replacing heavy components, such as engines or motors

- Fire and rescue teams

- Entertainment professionals to lift banners, speakers, and theatrical rigging

They can also be used alongside gantry and davit cranes. The easy installation and use make it ideal for temporary projects, too.

The hoist will also come with a 12.0Ah battery to help with uptime. While you can use smaller Ah batteries, the runtime will be lower.

Are BatteryStars Easy to Operate?

One of the greatest benefits of a BatteryStar™ is how easy they are to operate.

Unlike levers or hand hoists, BatteryStars are controlled by a wireless remote. This is because many of the BatteryStar’s applications are temporary projects or projects where the hoist moves frequently.

The remote provides riggers with variable speed control and keeps them away from the loads path of travel.

Before operating, you want to ensure the hoist has a chain bag connected to it. From there, hook the hoist to a lifting point and turn on the control. You will want to press down on the power button in the top-right corner. A flashing green light will appear, which means it’s pairing with the BatteryStar™. (The BatteryStar™ is active as long as the green light stays on.) Once connected, you can operate the hoist from as far as 60′ away.

Can You Operate BatteryStars With a Computer?

As of now, multiple BatteryStars cannot be hooked up and operated simultaneously through a computer. BatteryStars can only be paired with an individual remote control.

What are the BatteryStar’s Safety Features?

The BatteryStar™ has multiple safety features built into it that wouldn’t be possible with a manual hoist. Some of them include:

Low Battery, Overload, and Operator Indicators

The BatteryStar’s remote has several safety icons. One of them is a low battery indicator, which emits a flashing red light once the battery is below 25%. If the battery is dead, a solid red light will appear.

If the hoist load is over 1-tonne, a red weight icon will pop up and the hoist will emit a buzzer sound. If overloaded, the hoist will only operate in a downward direction.

There are also several operator warnings if the hoist is below or above safe operating temperatures (0-104°F). It will also warn you if the hoist’s electronics stop working—this scenario will trigger a complete shutdown of the system.

Less Operator Effort and Fatigue

The remote-control system allows operators to safely operate the hoist and move the load from over 60′ away. This allows operators and riggers to control the load from a safe location.

Plus, the BatteryStar’s inverted system removes workers from carrying the weight of the hoist up to the anchor point—removing them from hard manual labor.

Added Load and Hoist Security

BatteryStars come with a built-in electronic and secondary mechanical clutch that provides added protection from hoist overload.

The hoist is designed to withstand prolonged weather exposure and harsh environments.

It also has a brake inspection window on the top and bottom of the hoist to allow operators to better implement preventative maintenance measures.

What Industry Standards Impact a BatteryStar™?

BatteryStars abide by ASME B30.16 Overhead Underhung and Stationary Hoists standards.

Meanwhile, the hooks will fall under ASME B30.10 Cableways, Cranes, Hoists, Hooks, Jacks, and Slings.

How Often Should You Inspect BatteryStars?

Like all chain hoists—battery or manual—BatteryStars should have a consistent inspection schedule to ensure reliable operations.

Your inspection cadence will depend on how much the hoist is used. You should never go a full year without a periodic inspection of a BatteryStar™. But, if you find yourself using it daily on heavier loads, you should consider inspecting it two, three, or four times a year.

This is what ASME B30.16 Overhead Underhung and Stationary Hoists standards say regarding inspections.

Section 16-2.1: Inspection

“(b) There are five types of inspections required, each directed toward a different set of circumstances. They are the following:

(1) ) initial inspection

(2) ) preoperation inspection

(3) frequent inspection

(4) periodic inspection

(5) inspection of hoists not in regular use”

While you as the owner of the hoist are responsible for inspecting your hoists and other rigging equipment pre-shift, or before each lift, a Mazzella or Columbus McKinnon representative can offer advice on frequent and periodic inspection frequencies based on your application.

Do BatteryStars Have a Warranty?

Yes. Columbus McKinnon offers a five-year warranty for all BatteryStars and their parts. There is also a three-year warranty on the Milwaukee M18™ Red Lithium Battery.

It’s also worth noting that common service parts are available for replacement.

Is the BatteryStar™ Right for You?

Investing in a battery-operated hoist is also an investment in your workers’ safety.

A BatteryStar provides riggers the best of both worlds. Not only do you get the strength and speed of an electric chain hoist, but you also get the convenience of a cord-free operation that provides the portability and ease of use of manual hoists.

They’re simple to use and built with safety in mind. Whether you’re an EHS Manager, an Operations Manager, or a Plant Engineer, the BatteryStar™ is a must-have tool for any company looking to improve their lifting operations and better employee safety.

The BatteryStar™ Hoist can be purchased through any Columbus McKinnon distributor in the United States, including Mazzella, who has been a proud distributor of Columbus McKinnon products for decades.

Contact our team to learn more about the BatteryStar™ and how to purchase one for your business. Our specialists can answer questions regarding pricing, availability, and application issues.

Make sure to watch our video with Columbus McKinnon to learn even more about this amazing new product.

Copyright 2024. Mazzella Companies.