What’s a Tagline, and How Can It Help With Load Control?

Are you looking for a way to make your jobsites safer, but have questions about how to do so? One thing that could help is using taglines to prevent spinning and pendular motion of loads being lifted.

“Safety doesn’t happen by accident.”

This quote from an unknown author is as true now as it was the day it was first spoken, especially when it comes to staying safe in the industrial, construction, and manufacturing industries.

“Line of fire” is a term used to describe being in harm’s way on a job site. A person in the path of an object or hazardous energy is considered in the line of fire. Over 25% of all workplace fatalities result from line-of-fire incidents.

The use of taglines is a major way to prevent line-of-fire injuries during overhead lifts, as are planning your lifts, and identifying safety concerns on a job site.

By the end of this article, you’ll be able to:

- Describe what a tagline is

- Define what it means to be in the “line of fire”

- Understand the purpose of a Job Safety Analysis (JSA)

- Identify line-of-fire hazards

- Describe how to protect yourself and others from line-of-fire hazards

What Is a Tagline?

According to the OSHA 1926.1401 standard, “a tagline is a rope (usually fiber) attached to a lifted load for purposes of controlling load spinning and pendular motions or used to stabilize a bucket or magnet during material handling operations.”

Taglines help you avoid having to put hands on, or stand underneath, a load during a lift. Its usage greatly reduces the times where you are “in the line of fire,” which means being in danger of getting struck by or pinned underneath a load. If something goes wrong and a load swings out of control or falls to the ground after a complete rigging failure, taglines will keep you out of the fall zone. Taglines are used to make sure anything that could be deemed a hazard is controlled during an overhead lift. If you’re unsure of where the center of gravity is on a load to be lifted, a tagline can help you execute the lift safely. Also, if the object being lifted must be positioned through a facility, a tagline will help you guide the load to its destination while keeping you safe at the same time.

What Are Taglines Made of?

There are no set guidelines for what material taglines need to be made from, as it depends on the environment in which you are lifting.

Example: You would not use a tagline made of a conductive material around a power line. Also, you would not use a light-grade rope that could fray or tear when exposed to sharp or abrasive edges.

There are no standards that dictate the usage of taglines. Commonly, taglines are used on a case-by-case basis as tools to avoid being in the line of fire on a job site. However, it may not always be the best solution.

How Do I Determine if I Need a Tagline?

Having a lift plan is probably the biggest “must-have” for any overhead lift, regardless of your usage of taglines.

During the planning stage, you will identify if a tagline or orientation-control device like the Verton EVEREST SpinPod are needed, or if a barricade will be sufficient at keeping workers out of the work zone. These plans are critical because if a problem can be foreseen, if a lift does fail, your risk of injury / death likely would be diminished.

Lifting plans are similar to a job safety analysis (JSA) or job hazard analysis. If you’re doing a pre-exam of your work site, you will be able to identify where potential hazards exist for your workers.

By doing lift plans and job safety analyses, you may discover the need for a tagline if there’s a hazard to any employee because you can’t keep your load under control. The tagline would be a way to mitigate that potential hazard, as it would prevent workers from having to stand near the load being lifted.

Can Taglines Prevent Load Failures?

Are taglines used because the uncontrolled spinning or other motion of a load could result in the failure of a sling or lifting device?

While taglines can be used for this reason, their main existence is to prevent a load from swinging into a piece of equipment, nearby structure, or person working on the job site. Taglines are used to make sure the load gets to where it needs to be and get it to the ground safely.

What If Taglines Will Not Work for Me?

Before determining whether taglines will work for your lifts, you want to make sure you have the right rigging equipment. Then, you want to make sure you and your team:

- Have received training on the use of lifting and rigging equipment

- Know how to develop the lift plan

- Conduct inspections on lifting gear prior to each shift

If after going through these steps, you realize taglines may not work for you, no-touch tools could be the answer. No-touch hand tools are designed literally to take your hands off the load set to be lifted. You can use a reach stick or another device to help position a load rather than putting yourself at risk by getting closer to the lift.

Mazzella offers a variety of no-touch hand tools that will help keep you away from pinch points, and at a distance away from the load. All devices are available in various lengths and handle types.

What Types of Hazards Can Taglines Help Mitigate?

Struck-By Hazards

Struck-by injuries are “a result of forcible contact or impact between the injured person and an object or piece of equipment that is in motion.”

Struck-by incidents are caused by objects that are:

- Flying

- Falling

- Swinging

- Rolling

Examples include being struck by loads lifted by a crane.

These types of incidents can be prevented by following procedures, securing tools and other loose objects, wearing PPE (personal protective equipment), and staying out of the line of fire.

Remember, you never want to walk under suspended loads or elevated work platforms and need to look for objects that could fall or roll. When working around vehicles or heavy equipment, stay in the operator’s view and get their attention before approaching or crossing paths. Never assume you have the right of way.

Importance of Using Proper PPE

In your JSA and lift plan, you have to spell out the PPE needed on the job site.

While utilizing a tagline, you want to make sure you’re using the right glove on for the material used in the tagline’s construction. Also, if you’re working with an overhead lift, you want to make sure you’re wearing a hard hat.

When working with crane operators, make sure you understand and know proper crane signals. This communication is vital for the successful and safe delivery of loads to their intended spots on a job site.

Along with PPE, situational awareness is critical to making safe overhead lifts. With taglines, you want to position yourself accordingly. Don’t put yourself in a position where you could experience a close call or be crushed if a load swings, spins, or fails.

Caught-in or -Between Hazards

Caught-in or -between injuries are “a result of a person being squeezed, caught, crushed, pinched, or compressed between two or more objects, or between parts of an object.”

Examples of caught-in or -between incidents include being:

- Crushed by heavy equipment

- Pulled into operating machinery

- Engulfed in a trench by a cave-in

To avoid getting caught-in or -between injuries, be familiar with the equipment in your workplace, make sure guards are in place, and never place any part of your body in the line of fire near operating equipment. Be aware of your surroundings and never position yourself between moving equipment and solid objects.

Released Energy

When stored (potential) energy is released unexpectedly, anyone in the line of fire can be seriously injured or killed.

There are many forms of potential energy, including:

- Electrical

- Mechanical

- Chemical

- Gravitational

Be aware of the dangers of potential energy associated with:

- Elevated loads

- Springs

- Capacitors

- Flywheels

- Pressurized gases

- Chemicals

To prevent injuries, follow lockout / tagout procedures and other safe work practices for controlling hazardous energy. Equipment must be de-energized and potential energy must be dissipated or isolated. Always test to make sure all forms of hazardous energy have been successfully removed or isolated.

Why Is a Job Safety Analysis Important?

A job safety analysis (JSA) focuses on the relationship between the worker, the task, the tools, and the work environment — and identifies hazards before they cause catastrophic injury / death.

Identifying hazards is one of the first things you can do to help keep your job site safe. OSHA defines a hazard as a condition, or set of circumstances, which present a potential for harm. A hazard is often associated with a condition or activity that will cause illness (health hazard) or physical harm or injury (safety hazards).

Hazards are the main cause of occupational health and safety problems. The single most effective way to assess safety management on your job site or facility is to perform a Job Safety Analysis, or JSA.

After a hazard is identified, a determination is made on how to control or eliminate the hazard altogether. This plan needs to be communicated with all individuals involved to gain clarity on safe work. Anytime the job, task, or situation changes, the JSA plan needs to be revisited.

Taking the time to perform a job safety analysis is truly invaluable. By controlling or eliminating hazards in the workplace, you help reduce the risk of an accident. Think about how quickly the costs of a workplace accident or fatality can add up, including:

- Lost wages

- Workers’ compensation

- Low employee morale

- Decrease in productivity

- Workforce shortages

What to Look for When Conducting a Job Safety Analysis?

When performing a JSA, start by identifying potential hazards for jobs or activities that are considered higher risk.

The first thing that you should do when performing a job safety analysis is identify the types of jobs or activities that you or your co-workers perform that could be considered higher risk. Think along the lines of jobs that:

- Have the highest injury rates

- Feature the potential to cause the most severe or disabling injuries

- With one simple human error, could lead to a severe accident or injury

- Are new to your operation or have undergone changes in process and procedure

- Are complex enough to require written work instructions

In addition to reviewing high-risk jobs or activities, you can also review any type of applicable OSHA standards for your industry and use those to formulate scenarios that become the basis for identifying existing hazards. Think in terms of using any applicable OSHA standards for fall protection, equipment operation, hazardous materials, inspection, lockout / tagout, etc. as a starting point.

Once you’ve identified potentially risky jobs or activities, apply each of the following questions and document your answers:

- When I perform this job or activity, what can go wrong?

- What are the consequences?

- How could it arise?

- What are other contributing factors?

- How likely is it that the hazard will occur?

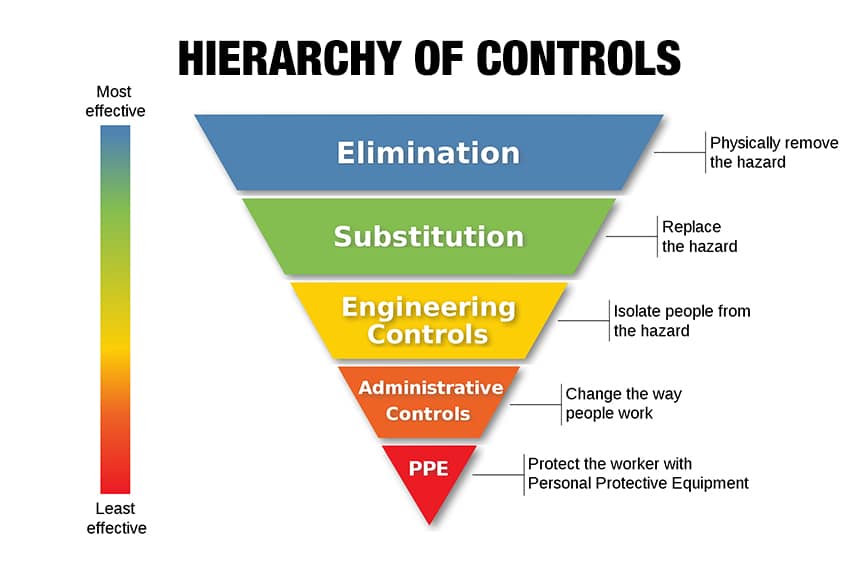

The Hierarchy of Controls

When looking for job site hazards, keep in mind the Hierarchy of Controls, which is a standard concept for minimizing exposure to situations that increase risk of serious injury / death.

According to the Hierarchy of Controls, these are the ways to eliminate job site hazards, starting with the most effective way and going to the least effective measure:

- Elimination-Physically remove the hazard

- Substitution-Replace the hazard

- Engineered Controls-Isolate people from the hazard

- Administrative Controls-Change the way people work

- PPE-Protect the worker with Personal Protective Equipment

How Can Mazzella Help You Make Your Job Sites Safer?

Remember, safety is everybody’s concern, and uninformed or risky decisions made could have lasting negative effects.

As a company that not only offers solutions, but also, training, Mazzella takes the safety of your employees seriously. We would like to help you train your employees on how to safely perform their jobs.

We can help you become familiar looking for situations where there is potential for:

- Flying, falling, swinging, or rolling objects

- Getting squeezed, caught, crushed, pinched, or compressed between two or more objects, or between parts of an object

- Sudden release of stored energy

Also, we can help you and your workers better understand and follow the Hierarchy of Controls. You want to have ways to eliminate or control those hazards and position yourself out of the line of fire when executing overhead lifts and other applications where miscalculations or an unaccounted-for risk could have catastrophic results.

If the hazards can’t be eliminated, find an alternative that will protect you and your employees from catastrophic injuries or death.

Also, we can assist you in creating load safety. Offering and utilizing a no-touch tool to eliminate the need to position oneself near or under an elevated load is becoming more and more prevalent.

Call us at 800.362.4601 or click here to learn more about our training programs, or schedule a virtual or in-person consultation with one of our trainers.

Lifting & Rigging Training

If you require a specific training course for OSHA compliance, Mazzella can assist you in creating a safe and reliable workplace. We qualify our trainers by requiring them to complete an internal train the trainer program (which trains to applicable OSHA and ASME standards and training technique), extensive field experience, and additional training from third-party entities, such as Crosby, CM, Harrington, Gorbel, and Industrial Training International (ITI).

Copyright 2022. Mazzella Companies.