Year in Review: The Best Lifting and Rigging Articles of 2020

In the spirit of positive thinking and learning from our experiences in 2020, we've compiled a list of the top lifting and rigging articles we published this year. These articles could help you better understand risk in your business and help you understand new ways you can improve the safety and efficiency of your operations.

This article isn’t going to be a recap of the tumultuous year that was 2020. However, we do know that this year forced individual leaders, businesses, and industries to look inward and identify vulnerabilities and insufficiencies across all areas of their operations.

Many businesses pivoted to make employee safety and customer safety a top priority. For some, this resulted in a more significant investment in training, compliance, personal protective equipment (PPE), or developing more robust safety and quality programs.

This year also forced leaders to take a hard look at their business processes—allowing them to identify gaps or opportunities where they could make improvements and become more efficient in their operations.

In the spirit of thinking positively, and learning from our experiences in 2020, we’ve compiled a list of the top lifting and rigging articles we published this year. These articles could help you better understand risk in your business and help you understand new ways you can improve the safety and efficiency of your operations by:

- Investing in the training of your people

- Identifying dangerous lifting practices and/or improper lifting equipment

- Understanding the best product solution(s) for your job site or facility

- Selecting the right equipment for your overhead lifting applications

The Best Lifting and Rigging Articles of 2020

Sling Protection: What it Is, Different Types, and When to Use it

Do you find that you go through a lot of slings and have to constantly buy new ones? Or, have you noticed that load damage in your facility is often caused by the sling itself? Both of these issues are related to one of the most common rigging problems—lack of proper sling protection.

Sling protection is a common term thrown around in the rigging industry. Sometimes, it refers to how to properly care for your slings, but it also refers to protective products including pads, sleeves, and covers that are added to a sling, or the load itself, to prevent damage.

In this article, you’ll get a better understanding of:

- What sling protection means

- Why sling protection matters

- The risks of not properly protecting your slings

- Common sling protection products

Continue Reading…

Do You Know What Damaged and Unsafe Rigging Equipment Looks Like?

While the information provided in the ASME B30 Safety Standards is invaluable—especially when it comes to inspection frequencies and removal from service criteria—we often hear that there aren’t enough examples to show end-users real damage to equipment that warrants removal from service.

In this article, we share several real examples of slings, rigging hardware, and homemade lifting devices that our inspectors have removed during a rigging inspection. We also walk you through the reasons each device should be removed from service and identify the applicable OSHA and ASME standards that apply to each device.

Continue Reading…

Structural vs. Roll Formed Pallet Racking: Advantages and Disadvantages

When designing a pallet-racking system, a major consideration is whether to go with a structural or roll formed beam and upright construction. It’s important to understand the differences, benefits, and drawbacks of each system to determine which is the best fit for your warehouse.

In this article, we cover:

- What structural racking is and how it’s made

- Advantages and disadvantages of structural racking

- What roll formed racking is and how it’s made

- Advantages and disadvantages of roll formed racking

Continue Reading…

Alloy Chain Sling Assemblies: Parts, Configuration, and Terminology

Among the most versatile types of lifting slings, chain slings come in a wide variety of configurations. However, there is some terminology that’s used to identify the individual components and configuration of chain sling assemblies. These terms and identifiers can be confusing if you don’t understand the meaning behind them—especially when reviewing a quote or rigging inspection report.

In this article, we break down the following:

- The components of a chain sling assembly

- Chain sling terminology

- Examples of different chain sling configurations

Continue Reading…

Considerations for Maintaining Load Control When You Rig Your Next Lift

Even if a load is perfectly rigged according to its weight, without proper load control, the lift could fail and cause serious injury and damage. Rigging and maintaining load control is a complicated process that requires careful and educated planning.

In this article, you’ll learn more about how each of the following factors can impact load control during an overhead lift:

- Weight of the Load

- Center of gravity

- Slings and rigging equipment

- Sling hitches

- Fouling of the loud

- Tag line(s)

- Environmental conditions

- Load stabilization

Continue Reading…

How Do Twin-Path® Slings Compare to Wire Rope and Alloy Chain Slings?

We often get asked about alternatives to chain or wire rope slings that might save the end-user time and energy when rigging a load. Singmax® Rigging Solutions offers a line of high-performance Twin-Path® roundslings that combine the strength and toughness of wire rope or chain sling, with the weight-savings and ergonomics of a nylon or polyester sling.

For those of you who may be on the fence about converting to a synthetic sling, you’ll have a better understanding of:

- The technologies and extra engineering that separate Twin-Path slings from other synthetic slings on the market

- Common applications that Twin-Path slings are used for

- The benefits of using a Twin-Path sling

- Advantages and disadvantages of Twin-Path products compared to wire rope slings

- Advantages and disadvantages of Twin-Path slings compared to alloy chain slings

Continue Reading…

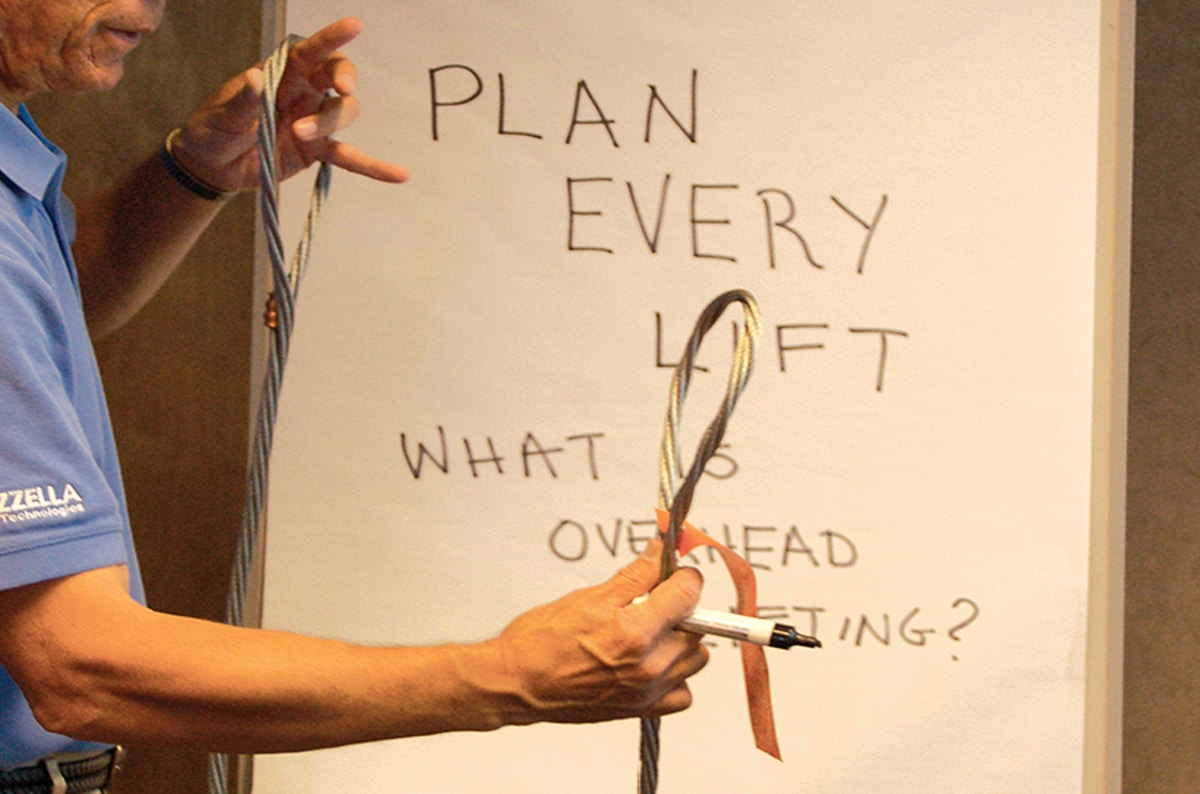

What is the Cost of Lifting and Rigging Training?

One of the questions we’re most frequently asked by customers is, “how much does your training cost?” While that answer depends on where you go and what your needs are, we can tell you more about our training program and some factors that affect our training costs. Customer training needs and requirements can vary, and there are numerous factors that should be considered when providing training for your employees.

In this article, you’ll get a better understanding of:

- What lifting and rigging training is

- How to determine if your employees need lifting and rigging training

- Factors that affect the price of lifting and rigging training

- Cost of Mazzella lifting and rigging training

- What Mazzella’s training program includes

Continue Reading…

Forklifts vs. Overhead Cranes: Which is the Best for Your Business?

When it comes to material handling, there are two standard options for lifting and moving loads—overhead cranes and forklifts. While these two types of machines both move material through your facility, there are distinct differences between the two—especially when it comes to safety and efficiency.

Our goal with this article is to help you establish a base-level understanding of forklifts and overhead cranes and how they differ from one another.

In this article, you’ll learn more about:

- What a forklift is and what it is used for

- Advantages and disadvantages of forklifts

- What an overhead crane is and what it is used for

- Advantages and disadvantages of overhead cranes

- Reasons to upgrade from a forklift to an overhead crane

Continue Reading…

Wire Rope Clips: Different Types, Installation, and Common Mistakes

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

However, it’s important to understand the different types of wire rope clips that are available and the correct application for each type. It’s also important to understand the right way and the wrong way to install wire rope clips to avoid a potential failure.

Continue Reading…

Crane Operator Training: Who’s Responsible for Training Your Employees?

If you have an overhead crane or lifting equipment in your facility, do you know which of your employees have received training and are competent or qualified to use that equipment? What requirements do you use to make that determination? Could you provide proof that your employees meet those requirements?

Many employers don’t understand who is responsible for providing training for employees who have been assigned the responsibility of operating an overhead crane or rigging a load. The use of cranes and other heavy lift equipment by employees who are inexperienced, or improperly trained, can result in dire consequences, including:

- Serious injury or death to themselves or co-workers

- Accidents resulting in property damage or damage to the load

- Negative impacts to project schedule and/or budget

In this article, you’ll learn more about your responsibility to train your employees and designate them as a qualified person, designated person, or competent person to operate that equipment.

Continue Reading…

Wrapping it up

Although this has been a difficult year for most, there have been many bright spots. We’ve seen companies double down and invest in the training of their employees through remote training or socially distanced in-person training programs. We’ve also seen our customers make significant investments in:

- New overhead crane equipment

- Upgrades or modernizations to existing crane equipment

- Fall protection and fall arrest solutions

- More comprehensive rigging inspection programs

- Improved storage or product flow with new racking or conveyor solutions

At Mazzella, we pride ourselves on being able to help our customers improve the safety and efficiencies of their business. When customers have a problem they need help with, we have a talented team of Engineers, Lifting Specialists, Product Specialists, and Technicians who can help design and develop a creative process or solution.

If you’d like an experienced and trustworthy partner in 2021, we’d appreciate the opportunity to provide a quote or consultation on your next overhead lifting or material handling project. Please contact us today to speak with a local and knowledgeable Lifting Specialist.

From all of us at Mazzella, we wish you and your employees a happy holiday season and continued health, safety, and success in 2021!

<!–[if lte IE 8]><![endif]–>

hbspt.cta.load(3336966, ‘2bda6101-2ff0-4331-8f26-0b8fb85907f0’, {});

hbspt.cta.load(3336966, ‘2bda6101-2ff0-4331-8f26-0b8fb85907f0’, {});

Copyright 2020. Mazzella Companies.