Class 1 vs. Class 2 Self-Retracting Lifelines (SRLs): What’s the Difference, and Which One Do You Need?

Learn the key differences between Class 1 and Class 2 SRLs under ANSI standards, how fall clearance impacts safety, and which device is right for your jobsite.

Estimated reading time: 8 minutes

We covered this topic on our YouTube Channel

When workers perform tasks at height, their safety depends on selecting the right fall protection equipment. Self-retracting lifelines (SRLs) are a vital part of any personal fall arrest system. But not all SRLs are the same.

Since the release of the ANSI/ASSP Z359.14-2021 standard, SRLs are now divided into two categories: Class 1 and Class 2. Each is designed for specific applications and performance levels. Understanding the difference is critical to ensuring compliance, controlling costs, and keeping your team safe.

In this article, with the help of our in-house fall protection experts, we’re going to cover everything you need to know about Class 1 and Class 2 self-retracting lifelines, helping you keep your workers safe while at height.

Table of Contents

- What Are Self-Retracting Lifelines (SRLs)?

- What Is the Difference Between Class 1 and Class 2 SRLs?

- Why Does Fall Clearance Matter for Workers at Height?

- What are Real-World Applications for SRLs?

- What Does ANSI Z359.14-2021 Require?

- Why Are Class 2 SRLs Worth the Extra Investment?

- The Importance of Rescue Planning in Fall Protection

- Final Thoughts on Choosing the Right SRL for the Job

- Frequently Asked Questions About SRL Systems

- Learn More About Fall Protection Best Practices

What Are Self-Retracting Lifelines (SRLs)?

A self-retracting lifeline (SRL) is a connecting device that automatically retracts and extends as a worker moves. If a fall occurs, the SRL locks immediately, limiting the free-fall distance and minimizing impact forces.

SRLs must be used as part of a complete fall arrest system that includes an anchor point, full-body harness, and connecting device. Together, these components protect workers who perform tasks at height in industrial, construction, and maintenance settings.

What Is the Difference Between Class 1 and Class 2 SRLs?

The core distinction between Class 1 and Class 2 SRLs is where and how they can be anchored. Class 1 SRLs are designed exclusively for overhead tie-off, while Class 2 SRLs can be used overhead, at the D-ring level, or for foot-level tie-off.

| Feature | Class 1 SRL | Class 2 SRL |

| Primary Use | Overhead anchorage only | Overhead, D-ring level, or below (foot-level tie-off) |

| Fall Clearance | Requires more clearance and vertical space | Uses additional braking and energy absorption to reduce required clearance |

| Braking Mechanism | Standard internal brake | Dual internal and external braking with added shock absorption |

| Common Environments | Catwalks, overhead platforms, maintenance areas | Construction sites, crane bridges, steel mills, or variable anchor points |

| Typical Cost Range | $200–$300 | $300–$500 depending on configuration |

| Applicable Standard | ANSI/ASSP Z359.14-2021 | ANSI/ASSP Z359.14-2021 |

| Versatility | Limited to overhead | Multi-position capable for various tie-off scenarios |

Class 2 SRLs are designed for greater flexibility. They can safely arrest a fall even when the anchorage point is below the worker’s D-ring, which is often the case in construction, on overhead cranes, and in many general industry environments.

Why Does Fall Clearance Matter for Workers at Height?

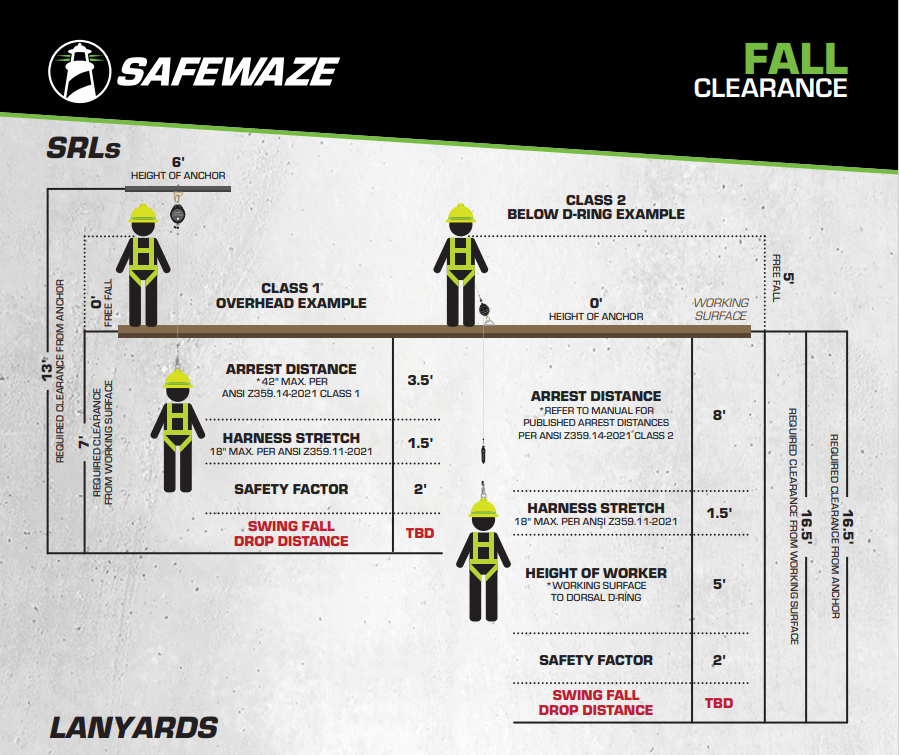

Fall clearance, which is the minimum vertical distance between the worker’s anchorage and the next lower level or obstruction, is one of the most critical considerations when selecting an SRL system.

The total clearance required includes the SRL extension, deceleration distance, harness stretch, and the worker’s body length, with an added safety buffer. If the total distance is miscalculated, the worker could strike a lower level before the fall is fully arrested.

Class 2 SRLs are specifically engineered to minimize this risk. Their enhanced braking systems and energy absorbers reduce the total fall distance, making them ideal for environments where limited fall clearance or foot-level tie-off is unavoidable.

What are Real-World Applications for SRLs?

In industrial environments, SRLs are frequently used with overhead cranes, steel fabrication lines, and maintenance platforms.

For example, technicians accessing the top of a crane bridge to perform electrical or mechanical work often require full mobility along the crane’s length. In this scenario, a sliding beam anchor combined with a Class 2 SRL allows continuous movement while maintaining OSHA compliance and minimizing swing fall risk.

Adding a fall protection system during the initial crane fabrication stage is also highly cost-effective. When installed as part of the build, the cost of a rail or lifeline system is minimal compared to retrofitting it later. This will save your business thousands of dollars in additional mobilization, equipment rental, and downtime.

Beyond cost savings, integrated systems ensure immediate OSHA compliance and improved safety during routine maintenance, inspections, or emergency repairs.

What Does ANSI Z359.14-2021 Require?

The updated ANSI/ASSP Z359.14-2021 standard redefined SRL classifications to make performance expectations clearer and testing more consistent. Key points include:

- Class designations (1 or 2) must appear clearly on SRL housings and in manuals.

- Arrest distance limits: Class 1 SRLs must stop falls within 24 inches; Class 2 within 42 inches.

- Testing for leading-edge exposure: Class 2 SRLs must pass additional sharp-edge and swing-fall testing.

- Updated labeling ensures users can easily identify the SRL class and intended application.

Manufacturers now follow stricter performance testing for both overhead and foot-level tie-off conditions, improving reliability and helping safety managers make informed purchasing decisions.

Why Are Class 2 SRLs Worth the Extra Investment?

While Class 2 SRLs often carry a slightly higher upfront cost, they deliver measurable long-term value. They reduce inventory complexity by replacing multiple types of devices with one versatile model, simplify training, and provide added protection across more jobsite conditions.

They also help eliminate one of the most common sources of misuse, which is workers accidentally using an overhead-only device for a below-D-ring tie-off situation. By standardizing Class 2 SRLs where possible, companies can reduce compliance risk, minimize swing fall exposure, and streamline their overall safety program.

In short, a Class 2 SRL does everything a Class 1 does…and more.

The Importance of Rescue Planning in Fall Protection

Even the best fall arrest systems are incomplete without a proper rescue plan. OSHA requires that all jobsites where workers are exposed to fall hazards have a documented plan for retrieving a fallen worker quickly and safely.

Suspension trauma can occur in as little as five minutes after a fall arrest, which means time is critical. A well-designed rescue plan should include equipment like suspension relief straps, retrieval systems, and clearly assigned rescue roles.

Final Thoughts on Choosing the Right SRL for the Job

If your team always ties off to an overhead anchor with ample clearance, a Class 1 device may be sufficient. But for most modern workplaces—especially where tie-off points vary in height—a Class 2 SRL offers the adaptability, safety, and compliance protection your team needs.

For help selecting the right SRL, designing a system, or developing a comprehensive working at height rescue plan, contact Mazzella’s Fall Protection Division, who has decades of combined in-field experience.

Whether you’re onboarding new employees or reinforcing best practices with your current team, our Fall Safety 101 Infographic Poster is a free visual guide that breaks down OSHA height requirements, key equipment components, and the hierarchy of fall protection controls.

Frequently Asked Questions About SRL Systems

Learn More About Fall Protection Best Practices