What Is the Inspection Criteria for Fall Protection Wire Rope SRLs?

Do you know the rejection criteria for your fall protection wire rope SRL? There are many types of damage that, independently of each other, will require a wire rope SRL be removed from service.

“At the end of the day, the goals are simple: safety and security.”

The words of American politician Jodi Rell are as true today as they were when first spoken, especially as it relates to personal fall protection equipment. Wearing personal fall protection equipment while working at height, including self-retracting lifelines (SRLs), is the key to returning home safely at the end of every shift.

SRLs are critical pieces of “personal fall protection,” and approved for use in:

- Fall arrest

- Positioning

- Confined space rescue

- Ladder climbing devices

Keeping your SRLs in proper working condition is the best way to protect against a failure that could result in injury or death. Also, regular inspections are required by the OSHA 1926 and ANSI Z359 standards.

In this article, we will look at the following:

- When SRLs need to be inspected

- If an SRL tag is legible, what happens next?

- What type of inspections shall an SRL receive?

- Who performs SRL inspections?

- What are the requirements for a SRL inspection?

Why Is Personal Fall Protection so Important?

According to OSHA Publication 2056, there are nearly 6,000 workplace fatalities in the United States and 50,000 deaths due to workplace-related illnesses each year. Also, there are 5.7 million non-fatal workplace injuries, and those injuries alone cost U.S. businesses over $125 billion annually.

Falls are the leading cause of death in the construction industry, and most fatalities happen when employees fall from open-sided floors and through floor openings. Falls from as little as 4’ to 6’ can cause long-term time away from work, or death. This means all open-sided floors and platforms 6’ or more in height must be guarded.

Personal fall protection involves the use of several components, including:

- Harnesses

- Lanyards

- Self-retracting lanyards (SRLs)

- Anchor points

What Is a Wire Rope SRL?

An SRL is a deceleration device that functions like a seatbelt. During normal movement, the SRL can be released or retracted, but if a fall does occur, the device locks, which minimizes the fall length.

Wire rope provides the connection between the SRL unit and the hardware that attaches to a harness.

When Does a Wire Rope SRL Need to Be Inspected?

There are two instances in which you want your SRLs inspected:

- Periodic inspection of these devices by a competent person

- Daily inspections before each use

When performing daily inspections, you need to look to OSHA and ANSI standards, which will be more specific to the types of personal fall protection being inspected.

Do You Need to Be Certified to Inspect Your SRL?

The answer is no. What you’re looking for is competency. Have you been trained on the inspection of an SRL? Has your company designated you as competent to do so?

The daily pre-use inspection is a non-documented inspection. The periodic inspection conducted by a competent person needs to be documented. That is the only difference between the types of inspections. Otherwise, when the end-user gets their personal fall protection for the day, they’re going to perform the same level of physical inspection performed in the documented inspection. The annual level is documented, but the competent person is the decision-maker regarding if it stays in service or is removed.

At a minimum, a periodic inspection is needed once every year, and not to exceed 12 months. The frequency of the wire rope SRL periodic inspection is determined by the frequency and severity of its use. Environmental factors will determine how frequently these inspections are necessary.

When you’re inspecting the SRL, it is highly recommended that you use a protective glove, leather-based or Kevlar-based. As you’re running your hands across the wire rope SRL, and if there was a broken wire, the last thing you want to do is cause an injury while you’re doing an inspection trying to prevent an injury.

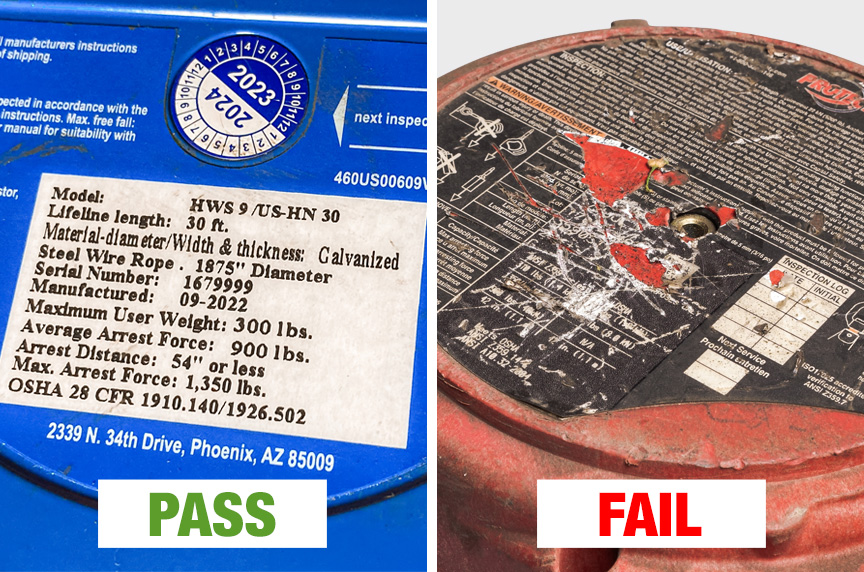

What Needs to Be on an Identification Tag?

When inspecting a wire rope SRL, the identification tag is often the first part that is inspected. The following items must be legible on the device’s tag:

- Use instructions

- Name of manufacturer

- Model number

- Unique serial number

- Date of manufacturer

- Type of cable used in the device

The only difference between a wire rope SRL and synthetic SRL identification tag is what type of material used. Also, the work instructions may be slightly different, especially regarding the inspection due to the types of material used to fabricate the device.

What Happens During a Wire Rope SRL Inspection?

If everything is legible on the tag and the SRL is not disqualified from service, inspectors will conduct a “hand-over-hand” inspection to make sure all of the hardware is original to the item and in place.

The inspector will look at the physical properties of the device. They’ll be looking for signs of:

- Corrosion

- Heat damage

- Arc burns

- Weld splatter

Hooks

According to the ANSI Z359 Fall Protection Code, markings for connectors shall be sufficient to provide traceability.

You have to go back to the manufacturer and model number to make sure the hooks being used on a product that’s currently in the field are up to current standards.

It’s very important to understand that “moving freely” is at basic fingertip-type pressure, and not excessive force. When an end-user is in the air, there shouldn’t be any fighting to maneuver the top hook. It should move smoothly.

After looking at the top hook, inspectors will work their way down to the bottom to check the bottom hook. Again, they are looking for any visual defects, and that everything operates freely.

In addition to seeing if the hook is swiveling properly, inspectors will examine the wire rope attachment and thimble. Also, they will check if the sleeve is properly swaged.

Wire Rope

Following the hooks, inspectors will go over the wire rope portion of the SRL. Next, they will check to see if any fasteners are missing from the device or if there are cracks in the housing.

For wire rope SRLs, including galvanized aircraft cable, or stainless steel aircraft cable, regardless of the length, the inspection is a hand-over-hand evaluation, and involves checking the brake. It is best that this step is done on a completely clean surface to avoid picking up any debris. If debris attaches to the wire rope, it can be pulled back into the unit and damage the SRL.

Also, you want to protect your hands because if you do discover a broken wire, and you’re letting this wire rope run through your hands, it is going to catch you. It is going to do some damage to your hand. By wearing gloves, you safely can catch snags of a broken wire or even a minor bend, dogleg or kink within the rope.

Braking System

Lastly, the inspector will test the braking system for proper operator, as well as if the wire rope reels back into the device properly. Additionally, the inspector will look throughout the inspection for signs of manual field repairs done or modifications.

This visual inspection can take some time because a hand-over-hand inspection must be performed through the SRL’s entire length. As inspectors do that, they’re going to check the braking system on a regular basis.

Once inspectors examine the entire length of the SRL, they will continue periodically checking the brakes for releases and catches. At the end of the visual inspection, if the tag reads legible, and no damage is found, inspectors will document this as a “pass” and leave it in service.

Who Performs These Inspections?

Generally speaking, end-users will play a large role in the inspection process because they need to inspect their personal fall protection equipment before it is used, as well as after it is removed, if others will be using it. Also, end-users will conduct initial inspections of new lanyards and SRLs to check for defects, and proper fit before they are put into service.

For periodic inspections, third-party companies often are hired to conduct and document their findings on personal fall protection equipment. When a customer hires a third-party company to conduct their periodic inspections, they have designated that company to do the inspection, and make determinations on the service life of personal fall protection equipment.

Can an SRL Be Repaired?

The short answer is yes, but it’s going to be manufacturer dependent.

If the manufacturer does not have field repair kits, the wire rope SRLs will need to be sent back to them for their own repair and re-certification process. The larger the SRL unit, the more repairable it’s going to be. A lot of the smaller units, especially those with 7’ or 11’ long wire rope, you have to refer to the manufacturer to see about the reparability.

If an SRL can be repaired, only the manufacturer of that device will be able to conduct those repairs.

What Happens if an SRL is Used in a Fall?

If you ever have a fall or situation that caused the device to activate, it needs to be pulled from service.

Following the activation, there needs to be an investigation as to why the device performed that way. You would have to contact the manufacturer to determine if they’re willing to take the device, repair it, re-certify and send it back to you.

Really, your life literally is hanging in the balance with this device. You want to make sure everything about it is about as perfect as it was from the factory in the very beginning.

How Can Mazzella Help With Your Fall Protection Needs?

Accidents while working at height are one of the biggest causes of workplace injury and death. You need to do your work safely and correctly. We can help with your fall protection needs, plans, equipment, and training.

Mazzella has custom-configured several types of fall protection systems for businesses across the country that have diverse needs based on their working conditions. Also, we are a distributor of The XSERIES Mobile Grabber® fall protection units.

Mazzella is a leading supplier and installer of engineered fall protection systems in the U.S., as well as a distributor of soft goods, including harnesses, lanyards, self-retracting lifelines, scaffolding and netting. All of our engineered systems and products meet or exceed the federal criteria required by OSHA and ANSI and can be customized with your individual fall protection and financial needs in mind.

Mazzella specializes in jobsite analysis and evaluation, as well as employee training for equipment installed or products sold. Also, we offer:

- General training

- Systems inspections

- Documentation storage

- Procedure development (i.e. rescue plans)

Rigging inspections are what Mazzella is known for. However, personal fall protection inspections pair well with our rigging inspection division.

What our rigging inspectors have found over the years is that while looking at the rigging in a facility, many of the workers using this equipment also use personal fall protection. Through our personal fall protection inspection training, we are competent to conduct these inspections.

Call us at 800.362.4601, or click here if you need fall protection equipment!

Fall Protection

Mazzella is a leading supplier and installer of engineered fall protection systems in the U.S., as well as a distributor of soft goods like harnesses, lanyards, self-retracting lifelines, scaffolding and netting.

We specialize in site analysis and evaluation, as well as employee training for equipment installed or products sold. Also, Mazzella offers general training, system inspection, documentation storage, and procedure development, like rescue plans.

Copyright 2023. Mazzella Companies.