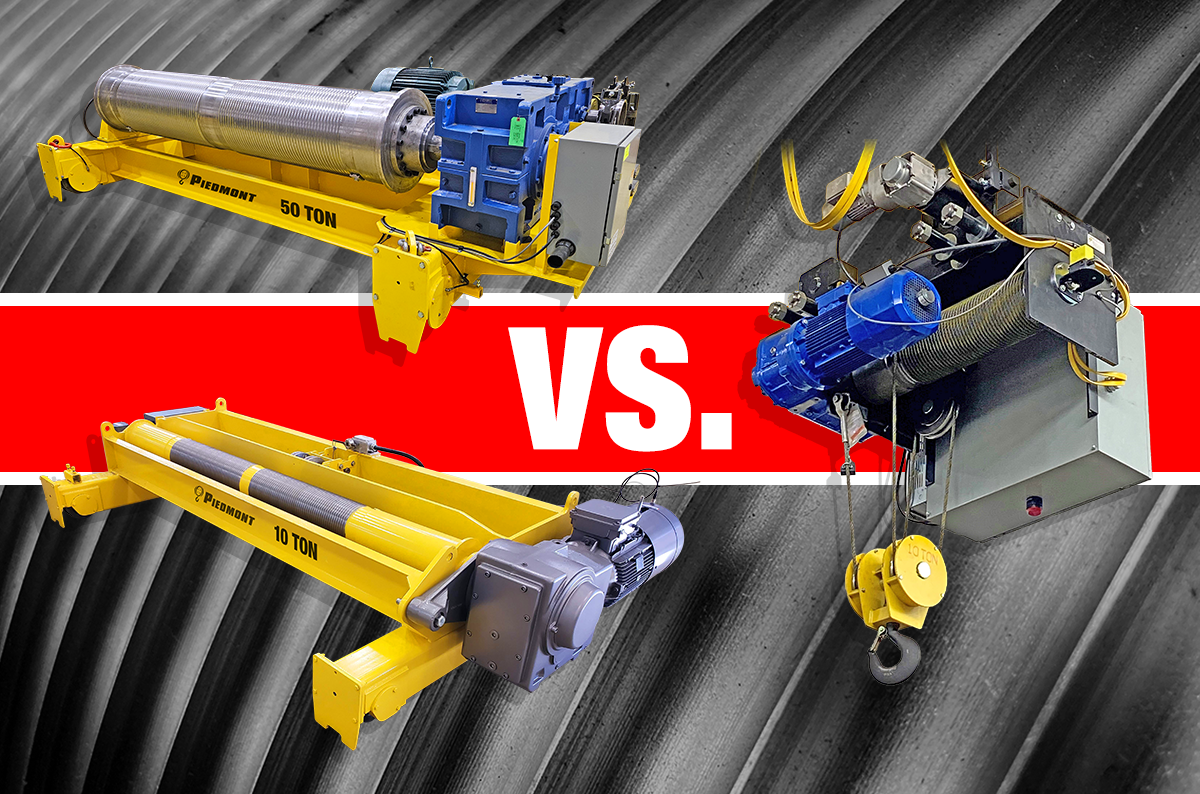

Built-Up Hoists vs. Package Hoist Systems for Overhead Cranes

No component is more important than an overhead crane’s hoist because it’s the device that lifts, suspends, and lowers the load. Understanding the duty cycle and CMAA service classification of the crane will allow the manufacturer to specify a hoist system that is durable enough to withstand the load and usage requirements.

At Mazzella, we engineer and build custom crane solutions ranging from light-duty economical cranes to large capacity, high duty cycle cranes with welded plate box girders. Our Engineers put careful thought into selecting or designing the crane’s hoist system for durability, efficiency, and cost-effectiveness.

In this article, we’ll explain why it may be necessary to invest in a built up hoist to prolong the service life and increase the production capabilities of your overhead crane system.

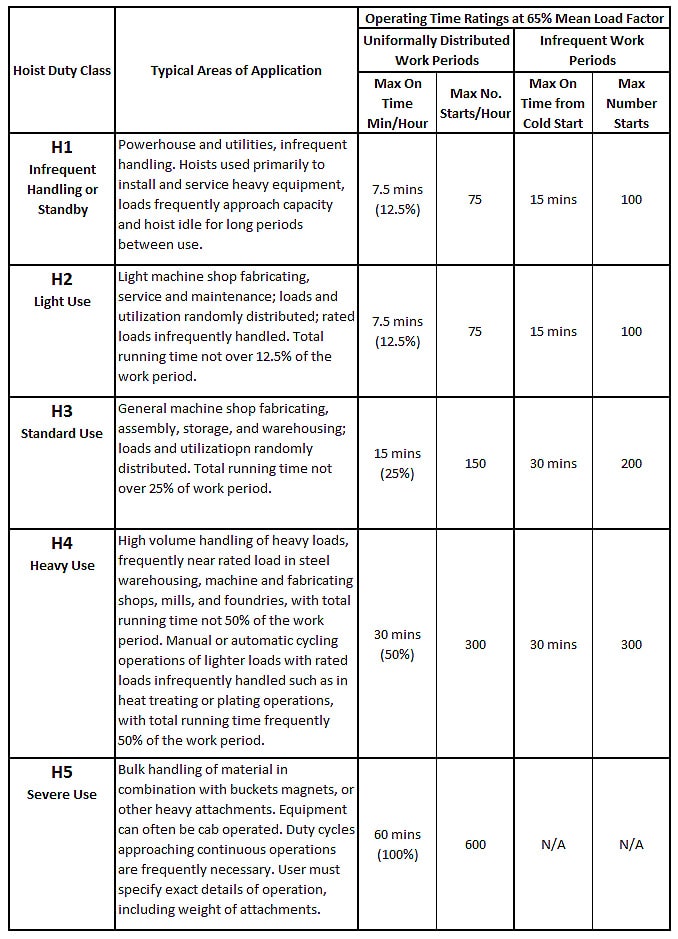

HMI / ASME Hoist Duty Classifications

Before we dive into the different types of hoists, let’s get an understanding of how hoists are classified. For electric hoists, there are five main duty classifications outlined by HMI/ASME. Each duty cycle classification takes a number of factors into consideration, including the following:

- Average operating time per day

- Load spectrum

- Starts per hour

- Operating periods

- Equipment life

See the chart below for guidelines on hoist duty cycle classifications on lifting application, max run time, and max number of starts for uniformly distributed or infrequent work periods.

What is a Built-Up Hoist?

Built-up hoists are highly-engineered and completely integrated systems that are used primarily on Class D, E, and F cranes. These hoist systems operate on process cranes and are built to withstand high-output production and demanding industrial environments. No two built-up hoist systems are alike as they’re completely customized for the job at hand.

Some of the applications where a built up hoist might be utilized include:

- Automation

- Bucket hoists

- Ladle and charging hoists

- Explosion proof hoists

- Magnet service

- Wet and dry end paper-mill service

- Turbine handling

- Critical lifts

- Die flipping and metal coil handling

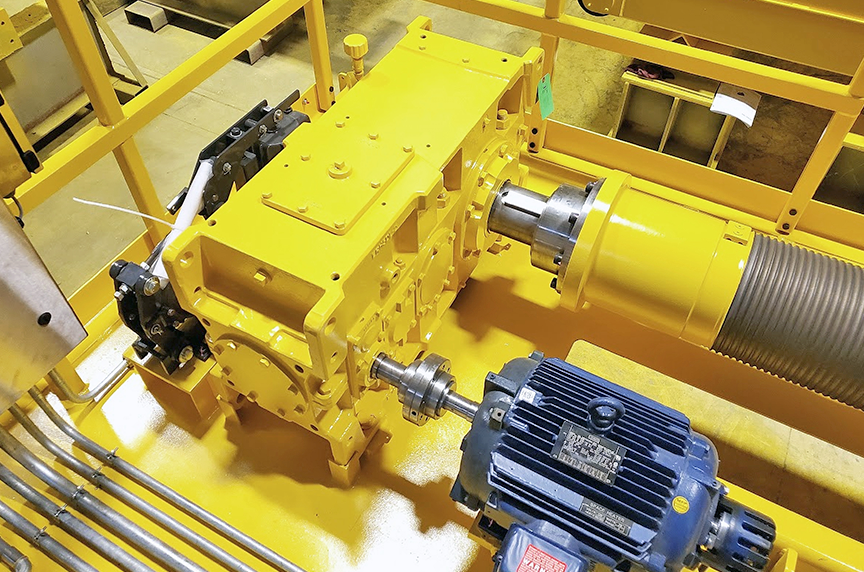

A built-up hoist consists of robust and specially-designed components that are designed to work together to accomplish a very specific and precise lift. Some of these components include:

- Drums

- Motor

- Gear box

- Couplings

- Sheaves

- Encoder

- Brakes

- Limit switches

- Drives and control systems

- Festooning

Many of these components are precision-machined to very specific tolerances and designed to last so they can perform a complex or critical lift over and over again. The materials used on a built up hoist are often high alloy, heat-treated/hardened, and precision welded to reduce stress, fatigue, and distortion within the system.

Advantages of a Built-Up Hoist

Package hoist systems are primarily designed to be used on lower duty cycle overhead cranes. They fit a specific design criteria and meet the duty cycle requirements of the crane based on their capacity and amount of use they’ll see during the course of their lifetime.

On a built-up hoist, all of the components are specifically engineered for a specific purpose and are designed to last a very long time. These are systems that do one thing very well and they thrive in applications where a complex lift is needed. It’s not unreasonable to see built-up hoists that can stay in service for 40 years or more when they’re designed properly!

Built-up hoists are also designed to be more reliable, easier to inspect, and easier to service and repair than a package hoist system. A catwalk or service platform is commonly found on cranes with built up hoists to allow maintenance and service personnel access to the hoist for inspection or maintenance.

These types of hoists often have individual grease ports for the roller bearings to allow for easy lubrication. The hoist and trolley are also designed to allow easy access to gear boxes, brakes, and couplings for adjustment or repair.

Built-up hoists are found on top running double girder crane systems. This design gives them the advantage of:

- No limits to the maximum span or capacity of the crane, hoist, or trolley

- The most overhead room

- The greatest hook height

On a new process crane, the system will come standard with modern features and technologies, which provide better controls, precision movement, and safety when moving a load through a facility. Some of these technologies include:

- Variable frequency drives

- Anti-sway technologies

- Slow down and stop limit switches

- Remote radio controls

- Monitoring and diagnostics

Utilizing diagnostics information, maintenance personnel can monitor the time between recommended maintenance intervals for individual hoist components. This also allows them to schedule preventative maintenance to help reduce equipment downtime.

For example, by monitoring the predictable preventative maintenance schedule, they can help improve the crane’s safety by knowing when the hoist components have reached the end of their useful service life so they can either rebuild the internal components or replace them entirely.

In a steel mill, automotive stamping facility, or mass-production environment, there really is no better option than a built-up hoist to handle technical and dangerous overhead lifts.

Disadvantages of a Built-Up Hoist

Cost would be the biggest disadvantage to specifying a built up hoist into an overhead crane system. The cost factors into the equation in many ways:

- Only compatible with top running double girder crane systems

- Additional engineering and design requirements

- Specialized components and lead times

- Additional transportation and freight costs

- More complicated / longer installation

Lower duty cycle cranes can utilize more standardized and economical hoists—resulting in significant cost savings. However, it can be argued that the initial investment into upgraded built-up hoist components and technologies will offset the costs of future maintenance and repairs. By taking the time to engineer the hoist to perform exactly as intended, and to withstand the rigors of the lift it will be performing, the hoist will experience a longer operating life and will be more durable and more reliable for the end-user.

Versatility would be another disadvantage to a built-up hoist. These hoists are designed to do one thing and do that one thing extremely well. Lower duty hoist systems have a little more flexibility in terms of how they can be used. They can pick various types of materials and vary the frequency of lifts within their capacity and duty cycle requirements.

Training and inspection would be another factor for the end-user. Even to a seasoned crane operator, there will be an adjustment period to get used to the way the crane handles and performs. If the crane operators were used to operating an older package hoist system, the controls and performance of a new built-up hoist can feel very different. The components of the hoist are also more complex and may require more training or a more seasoned inspector to perform frequent and periodic crane inspections.

Most crane manufacturers or service companies will offer training for the operators and in-house maintenance personnel once the crane system has been installed—these trainings can be fully customized based on the preferences of the business owner, operators, and maintenance personnel.

Wrapping it Up

For most Class A, Class B, and Class C applications, a standardized and economical hoist package is perfectly acceptable. Understanding the usage requirements of the crane, and the types of lifts and frequency of lifts it will be making, will help you select the right hoist for your lifting application.

However, a built-up hoist will be the better choice for some Class D, Class E, and Class F crane systems. The extra engineering and specialized components in a built-up hoist will allow it to thrive in abusive and complex lifting applications.

At Mazzella, we have over 50 years of experience in the overhead crane industry and have a highly-trained team of sales specialists, engineers, project managers, estimators, draftsmen, AWS certified welders, electricians, and fabricators. Our team will assist you in the process of designing, building, and installing the optimal overhead crane system for your facility or job site.

Since every business is unique, and no two cranes are alike, we offer free quotes and consultations for overhead and material lifting projects. If you’re interested in learning more about how an overhead crane system can improve the efficiency and safety of your facility, or want to schedule a consultation, contact us today to speak with a Crane Specialist.

Copyright 2018. Mazzella Companies.