Eye Bolts vs. Swivel Hoist Rings: Pros & Cons and Common Uses

Used as lifting or securement points during a lift, eye bolts and hoist rings are some of the most common types of rigging hardware.

Have the riggers in your facility ever incorrectly used an eye bolt in place of a hoist ring, or vice versa? Although eye bolts and hoist rings are used for similar applications, they differ greatly when it comes to design, capabilities, and features. It’s not uncommon to see an eye bolt bent or cracked during a lift when a hoist ring could have been used to better accommodate the rigging and support the load.

One of the most common questions we get is “what’s the difference between an eye bolt and a hoist ring and how should they be used?” In this article, you can expect to learn:

- What an eye bolt is and what it’s commonly used for

- Different types of eye bolts

- Advantages and disadvantages of eye bolts

- What a hoist ring is and what it’s commonly used for

- Different types of hoist rings

- Advantages and disadvantages of hoist rings

What is an Eye Bolt?

Used as a lifting or securement point, eye bolts are one of the most popular types of rigging hardware. Just like slings, sling hooks, and shackles, eye bolts come in a number of different designs and configurations. Eye bolts can be used as a connection point for rigging, anchoring, pulling, or hoisting applications.

Eye bolts are stationary lifting points and only certain types can accommodate angular lifts by factoring in a significant reduction to the WLL.

The rated load of an eye bolt ranges anywhere from 200 lbs. to 65,000 lbs. Depending on the size and shape of the load, lifts may be performed with the assistance of one or multiple eye bolts placed throughout the surface of the load.

Common Uses of Eye Bolts

Eye bolts can be used as a connection point for rigging, anchoring, pulling, or hoisting applications. They are often used to lift items like:

- Plates of steel

- Motors

- Dies

- Containers

In many cases, the eye bolt is a permanent engineered lifting point on a motor, container, or other industrial object. Eye bolts are best applied to lifting these items with a straight, in-line pull.

Different Types of Eye Bolts

One of the most important considerations when using an eye bolt is whether you need a shouldered or non-shouldered eye bolt.

Shouldered Eye Bolts

Shouldered eye bolts are designed with a shoulder at the point where the eye and the shank come together. This shoulder design reduces bending stresses on the shank and allows the eye bolt to be used for angular lifting if the shoulder is properly seated in the load.

If you are lifting with slings at ANY angle, you must use a shouldered eye bolt.

Non-Shouldered Eye Bolts

These eye bolts are designed without a shoulder, and can only be used for true vertical or in-line lifts.

Advantages of Eye Bolts

Price

Eye bolts are less expensive in comparison to hoist rings and are often purchased in bulk amounts. However, it’s not uncommon for eye bolts to be used, abused, and disposed of—as they’re inexpensive and non-repairable.

Ease of Use

Because eye bolts are a simple product lacking moving parts, they are relatively easy to learn how to use and visually inspect.

Disadvantages of Eye Bolts

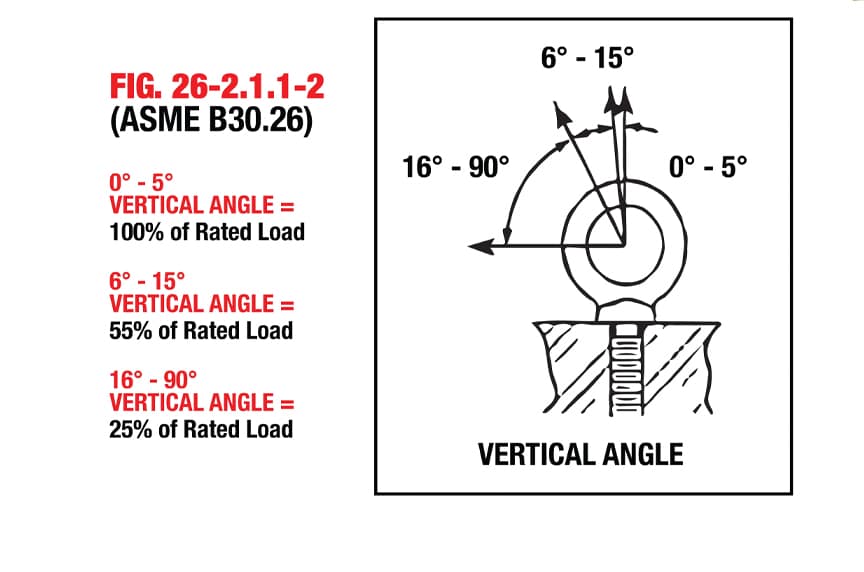

WLL Reduced During Angular Lifts

Angular lifts on an eye bolt will significantly lower the WLL and should be avoided whenever possible. If an angular lift is required, a properly seated shouldered eye bolt must be used.

Note: Not all shouldered eye bolts are rated for angular lifting. Be sure to consult with the manufacturer before use in an angular lift.

Stationary Lifting Point

While a hoist ring will swivel and pivot to accommodate the movement of the load, eye bolts remain stationary in the load for the duration of the lift. For this reason, eye bolts are best applied to straight, in-line pulls.

Rated Load

The max WLL of the largest eye bolt is about 65,000 lbs., while the hoist ring with the largest capacity can lift upwards of a quarter million pounds.

What is a Swivel Hoist Ring?

A swivel hoist ring—sometimes referred to as a swivel eye bolt—is a piece of rigging hardware that screws into an engineered lifting point on a load. This lifting point allows the rigging coming off of the hoist to connect to the load

The function of a hoist ring is similar to an eye bolt. However, a swivel hoist ring has the capability of pivoting and/or swiveling to accommodate lifting at angles without incurring damage to the device. Whereas, eye bolts are stationary and can only accommodate angular lifts by factoring in a significant reduction to the WLL.

The rated load of a hoist ring ranges anywhere from 800 lbs. to 250,000 lbs. Depending on the size and shape of the load, lifts may be performed with the assistance of one or multiple hoist rings placed throughout the surface of the load.

Swivel hoist rings can pivot 180° and/or swivel 360° from the screw’s axis to accommodate load movement while maintaining the full WLL.

Common Uses of Hoist Rings

Like eye bolts, hoist rings can be used as a connection point for rigging, anchoring, pulling, or hoisting applications. They are often used to lift items like:

- Plates of steel

- Motors

- Dies

- Containers

While hoist rings are often used to lift the same types of objects as eye bolts, they are best applied to situations where angular lifting is necessary.

Hoist rings are also necessary to use in a lift when an item is going to be flipped, turned, or manipulated in any way other than a straight, in-line lift.

Side-load and side-pull hoist rings are necessary in situations where the load needs to be side-mounted. This is especially common in stamping plants and molding operations where lifts frequently require turning, flipping, and other non-lateral movements.

Different Types of Hoist Rings

The most common types of hoist rings are:

- Swivel hoist rings

- Side-pull and side-load hoist rings

Swivel Hoist Rings

A swivel hoist ring—also known as a center-pull-hoist ring—is the most common type of hoist ring to come across on a job site. The bail, usually a U-bar, is connected through the center of the body with a pin in a clevis-like configuration.

A swivel hoist ring can both pivot 180° and swivel 360° while maintaining the full WLL. They cannot be used for side mounting, as the load could obstruct the bail’s range of movement.

Side-Pull and Side-Load Hoist Rings

Side-pull and side-load hoist rings are designed for side mounting only. The bail on these hoist rings is attached adjacent to the screw, rather than attaching directly above the screw.

These hoist rings will pivot and swivel to self-align with the load, but, unlike swivel hoist rings, do not maintain the full WLL as the bail pivots.

Advantages of Hoist Rings

Mobile Lifting Point

Unlike eye bolts, which remain stationary for the duration of a lift, hoist rings can pivot 180° and/or swivel 360° from the screw’s axis to accommodate load movement.

WLL Maintained During Angular Lifts

Unlike eye bolts, the WLL of a swivel hoist ring is not impacted by angular lifts. Swivel hoist rings are able to maintain their full WLL regardless of the lift angle.

Mounting From the Side

Side-pull and side-load hoist rings are designed and rated for side mounting. Eye bolts are not designed for any kind of side mounting.

Rated Load

The max WLL of the largest available hoist rings is around 250,000 lbs., while eye bolts with the largest capacities are only rated for about 65,000 lbs.

Disadvantages of Hoist Rings

Price

Because hoist rings have more moving parts, they do come at a higher cost than eye bolts. However, they tend to last longer and are usually repairable if damaged.

Ease of Use

Because hoist rings have more moving parts in comparison to eye bolts, learning to use and inspect these devices is more complicated. Hoist rings also require the use of an additional tool—a torque wrench—to ensure they’re properly torqued into the load.

Wrapping It Up

Hoist rings and eye bolts are common pieces of rigging hardware used as a securement point during an overhead lift.

An eye bolt is a simple piece of equipment consisting of an eye connected to a shank, while a hoist ring is a bit more complex.

An eye bolt functions as a straight, stationary lifting point, while a hoist ring functions like an eye bolt, but with the added capability to swivel and pivot. Hoist rings are often used in place of an eye bolt when an overhead lift is angular or requires manipulation of the load.

How We Can Help

At Mazzella, we stock and distribute eye bolts and hoist rings from several manufacturers, including:

- Jergens

- Crosby

- Actek

- ADB

- RUD

- Chicago

We also offer a large inventory of rigging hardware including hooks, shackles, rings, and more. If you want to schedule a consultation or receive a quote for your next lifting project, contact one of our Lifting Specialists today.

Rigging Hardware

Are you looking for access to a complete inventory of rigging and lifting products from the largest manufacturers in the world?

Contact us if you need shackles, hoist rings, eye bolts, hooks, master rings, links, turnbuckles, and more!

Learn more about lifting and rigging hardware!

Copyright 2020. Mazzella Companies.