The American Society of Mechanical Engineers (ASME) is a professional association and leading international developer of codes and standards associated with the art, science, and practice of mechanical engineering. ASME membership is comprised of engineers, scientists, government officials, and others who voluntarily contribute their technical expertise.

ASME standards and safety codes are intended to enhance public safety and offer best practices and applicable regulations within specific industries and jurisdictions. ASME standards are accredited as meeting the criteria of the American National Standards Institute (ANSI).

Every couple of years, the B30 Committee reviews, revises, and amends their existing standards and releases a new edition. The Committee revises the standards based on numerous considerations, including:

- Technological advances

- New Data

- Changing environmental and industry needs

In this article, we’ll discuss the revisions, updates, and additions to the newly released ASME B30.20-2021 Below-the-Hook standard, compared to the previously released 2018 edition.

What is ASME B30.20-2021 Below-the-Hook?

The first ASME B30.20 standard was issued in 1999, and since then, has been revised and published by the B30 Committee in 2003, 2006, 2010, 2013, and 2018.

The new ASME B30.20 Below-the-Hook standard revises and supersedes the procedures outlined in the 2018 edition of the same standard.

According to the standard itself, “ASME B30.20-2021 Below-the-Hook includes provisions that apply to the marking, construction, installation, inspection, testing, maintenance, and operation of below-the-hook lifting devices, other than components addressed by other ASME B30 volumes or other standards, used for attaching loads to a hoist. The requirements in this Volume also apply to clamps used for positioning and anchoring.”

What’s New in ASME B30.20-2021 Below-the-Hook?

There is new language revising paragraphs and subparagraphs in several sections, but many of the changes focused on the inspection requirements for different types of Below-the-Hook lifting devices.

Revisions were made in entirety to inspection requirements for the following devices:

- Structural and Mechanical Lifting Devices

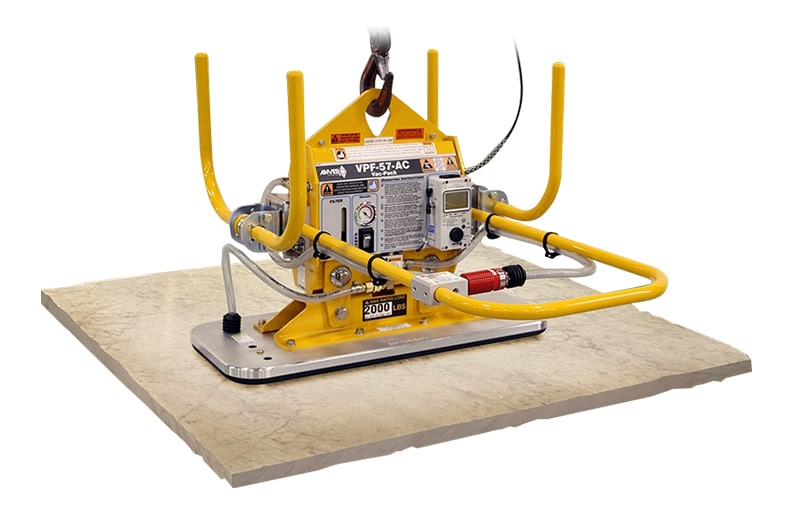

- Vacuum Lifters

- Close Proximity Operated Lifting Magnets

- Remotely Operated Lifting Magnets

- Scrap and Material-Handling Grapples

- Clamps

Breaking Down ASME B30.20’s Revisions

Structural and Mechanical Lifting Devices

During the “Inspection Classification” subsection, the “Frequent Inspection” and “Periodic Inspection” descriptions were revised. The “Frequent Inspection” subsection (d) now reads as: “special or infrequent service – as recommended by a qualified person.”

The “Periodic Inspection” subsection now reads: “Documented visual inspection of apparent external conditions to provide the basis for a continuing evaluation.

- Normal service for equipment in place – Yearly

- Heavy service-Semiannually

- Severe service-Quarterly

- Special or Infrequent service-As recommended by a qualified person before the first such lift, and as directed by the qualified person for any subsequent lifts.”

In the 2018 edition, the standard read:

Frequent Inspection

Visual examinations by the operator or other designated persons with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation. An external code mark on the lifter is an acceptable identification in lieu of records.

- Normal service for equipment in place — yearly

- Heavy service — semiannually

- Severe service — quarterly

- Special or infrequent service — as recommended by a qualified person before the first such lift and as directed by the qualified person for any subsequent lifts

The fully revised subsections for inspections now read as follows:

Frequent Inspection

“Lifting devices shall be inspected at intervals as defined in para. 20-1.3.1(b)(2). Conditions such as those listed in para. 20-1.3.7, or any other condition that may constitute a hazard, shall cause the lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires a repair, requires disassembly for further inspection, or will require more frequent inspection. The lifter shall not be returned to service until approved by a qualified person.”

Inspections must be conducted for the following:

- Structural members for deformation, cracks

- Excessive wear on any part of the lifter

- Loose or missing guards, fasteners, covers, stops

- Nameplates

- All functional operating mechanisms and automatic hold-and-release mechanisms for misadjustments interfering with operation

- Missing or illegible operating control markings

Periodic Inspection

“Complete inspection of lifting devices shall be performed at intervals as defined in para. 20-1.3.1(b)(3). Conditions such as those listed in para. 20-1.3.7, or any other condition that may constitute a hazard, shall cause the lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. The lifter shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-1.3.7, or the recommendations of a qualified person.”

Vacuum Lifting Devices

Like structural and mechanical lifting devices, vacuum lifting devices had revisions made to their “special service” subsection under “Frequent Inspection,” as well as all of the “Periodic Inspection” section.

In the 2018 edition, the standard read:

Frequent Inspection

Visual examinations by the operator or other designated persons with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation. An external coded mark on the vacuum lifting device is an acceptable identification in lieu of records.

- Normal service for equipment in place — yearly

- Heavy service — semiannually

- Severe service — quarterly

- Special or infrequent service — as recommended by a qualified person before the first lift and as directed by the qualified person for any subsequent lifts

The fully revised subsections for inspections now read as follows:

Frequent Inspection

“Vacuum lifters shall be inspected at intervals as defined in para. 20-2.3.1(b)(2). Conditions such as those listed in para. 20-2.3.7, or any other condition that may constitute a hazard, shall cause the vacuum lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires a repair, requires disassembly for further inspection, or will require more frequent inspection. The lifter shall not be returned to service until approved by a qualified person.”

Periodic Inspection

“Complete inspections of the vacuum lifting device shall be performed at intervals as defined in para. 20-2.3.1(b)(3). Conditions such as those listed in para. 20-2.3.7, or any other condition that may constitute a hazard, shall cause the vacuum lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. The vacuum lifter shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-2.3.7, or the recommendation of a qualified person.”

Close Proximity Operated Lifting Magnets

In the 2018 edition, the standard read:

Frequent Inspection

Visual examination by the operator or other designated persons with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation.

- Normal service for equipment in place — yearly

- Heavy service for equipment in place — quarterly

- Severe service — monthly

- Special or infrequent service — as recommended by a qualified person before the first lift and as directed by the qualified person for any subsequent lifts

The main changes to this standard were to the wording and descriptions within the frequent and periodic inspection subsections, and now state:

Frequent Inspection

“Lifting magnets shall be inspected at intervals as defined in para. 20-3.3.1(b)(2). Conditions such as those listed in para. 20-3.3.7 or any other condition that may constitute a hazard, shall cause the magnet lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for inspection, or will require more frequent inspection. The lifter shall not be returned to service until approved by a qualified person.”

Periodic Inspection

“Complete inspections of lifting magnets shall be performed and recorded at intervals as defined in para. 20-3.3.1(b)(3). Conditions such as those listed in para. 20-3.3.7, or any other condition that may constitute a hazard, shall cause the magnet lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. The magnet lifter shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-3.3.7, or the recommendations of a qualified person.”

Remotely Operated Lifting Magnets

In the 2018 edition, the standard read:

Frequent Inspection

Visual examination by the operator or other designated persons with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation.

- Normal service for equipment in place — yearly

- Heavy service for equipment in place — quarterly

- Severe service — monthly

- Special or infrequent service — as recommended by a qualified person before the first lift and as directed by the qualified person for any subsequent lifts

The frequent and periodic inspection criteria have been revised in their entireties. The fully revised subsections for inspections now read as follows:

Frequent Inspection

“Lifting magnets shall be inspected for damage at intervals as defined in para. 20-4.3.1(b)(1), including during operation for any deficiency that might appear between inspections. Conditions such as those listed in para. 20-4.3.6, or any other condition that may constitute a hazard, shall cause the magnet lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires a repair, requires disassembly for inspection, or will require more frequent inspection. The lifter shall not be returned to service until approved by a qualified person.

Periodic Inspection

“Complete inspections of lifting magnets shall be performed and recorded at intervals as defined in para. 20-4.3.1(b)(2). Conditions such as those listed in para. 20-4.3.6, or any other condition that may constitute a hazard, shall cause the magnet lifter to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires a repair, requires disassembly for inspection, or will require more frequent inspection. The magnet lifter shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-4.3.6, or the recommendations of a qualified person.”

Scrap and Material-Handling Grapples

Like the other subcategories of below-the-hook lifting devices, scrap and material-handling grapples had revisions done to several sections, and the frequent and periodic inspections were revised in their entireties.

In the 2018 edition, the standard read:

Frequent Inspection

Visual examination by the operator or other designated persons with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation.

- Normal service for equipment in place — yearly

- Heavy service for equipment in place — quarterly

- Severe service for equipment in place — monthly

- Special or infrequent service — as recommended by a qualified person before the first lift and as directed by the qualified person for any subsequent lifts

The fully revised subsections for inspections now read as follows:

Frequent Inspection

“Grapples shall be inspected at intervals as defined in para. 20-5.3.1(b)(1), including during operation for any deficiencies that might appear between inspections. Conditions such as those listed in para. 20-5.3.7, or any other condition that may constitute a hazard, shall cause the grapple to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires a repair, requires disassembly for further inspection, or will require more frequent inspection. The grapple shall not be returned to service until approved by a qualified person.”

Periodic Inspection

“Complete inspections of grapples shall be performed and recorded at intervals as defined in para. 20-5.3.1(b)(2). Conditions such as those listed in para. 20-5.3.7, or any other condition that may constitute a hazard, shall cause the grapple to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. The grapple shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-5.3.7, or the recommendations of a qualified person.”

Clamps

In the 2018 edition, the standard read:

Frequent Inspection

Visual examinations with records not required.

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

- Special or infrequent service — as recommended by a qualified person before and after each lift

Periodic Inspection

Visual inspection making records of apparent external conditions to provide the basis for a continuing evaluation. An external code mark on the clamp is an acceptable identification in lieu of records.

- Normal service — yearly

- Heavy service — semiannually

- Severe service — quarterly

- Special or infrequent service — as recommended by a qualified person before the first such lift and as directed by the qualified person for any subsequent lifts.

Now, under the “Every Lift Inspection” subsection, the first paragraph was revised to state: “Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated.”

However, the most significant changes came under frequent and periodic inspections. The fully revised subsections for inspections now read as follows:

Frequent Inspection

“Clamps shall be inspected at intervals as defined in para. 20-6.3.1(b)(2). Conditions such as those listed in para. 20-6.3.7, or any other condition that may constitute a hazard, shall cause the clamp to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. Clamps shall not be returned to service until approved by a qualified person.”

Periodic Inspection

“Complete inspection of the clamp shall be performed at intervals as defined in para. 20-6.3.1(b)(3). Conditions such as those listed in para. 20-6.3.7, or any other condition that may result in a hazard, shall cause the clamp to be removed from service. A qualified person shall determine whether any deficiency constitutes a hazard, requires repair, requires disassembly for further inspection, or will require more frequent inspection. Clamps shall not be returned to service until approved by a qualified person. The inspection shall be based on the manufacturer’s instructions, para. 20-6.3.7, or the recommendations of a qualified person.”

What Can Mazzella Do to Help You Stay in Compliance with ASME Standards?

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

We can design and fabricate all types of below-the-hook lifting solutions for any application, as all of our work is done in compliance with ASME B30.20 Below-the-Hook and ASME BTH-1 standards. Our products range from common lift beams to an engineered special 150-lb. engine line lifter, and a 330-ton electric furnace lifter.

We offer complete, in-house inspections, repairs, or recertification of below-the-hook lifting devices.

Certified Inspectors, along with our Engineering Department, perform detailed analyses of below-the-hook lifting devices. Repaired or rebuilt units provide significant cost savings. We also can provide FEA (Finite Element Analysis) reports and reverse engineering options on customers’ lifting devices. Customers can send in a unit, enabling Engineering to measure and model the unit in SolidWorks and run FEA analysis that determines the safe working load limit.

Click here if you need a repair or recertification of your lifting device.

Call us at 800.362.4601 or click here to specify your next below-the-hook project!

Below-the-Hook Lifting Devices

We can design and fabricate all types of below-the-hook lifting solutions for any application—all of our work is done in compliance with ASME B30.20 and ASME BTH-1 standards. Our products range from a common lift beam, to an engineered special 150 lb. engine line lifter, to a 330-ton electric furnace lifter.

Copyright 2022. Mazzella Companies.