How to Safely Use a Forklift Boom: Four Tips to Consider

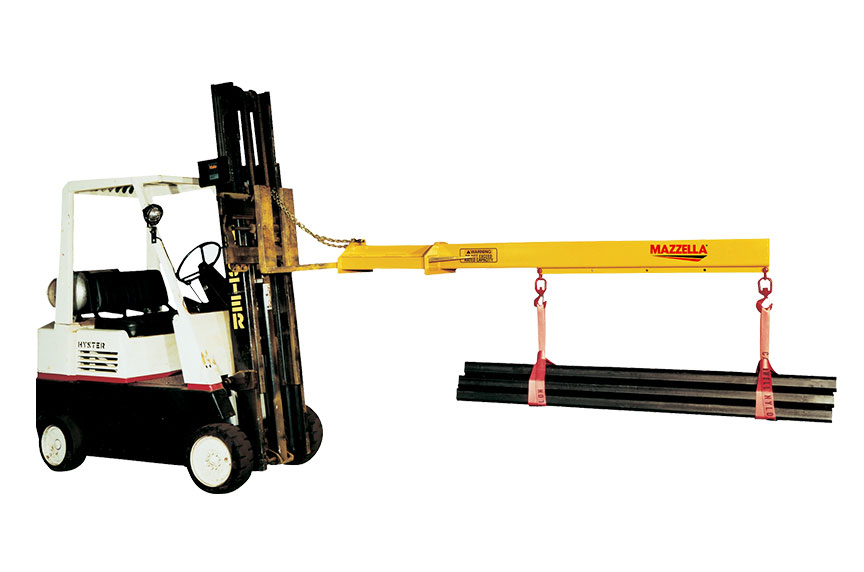

Forklift booms are a great and affordable device for organizations to invest in, but improper use can cause serious injuries and property damage. This article will review tips on how to safely use one and cover industry standards you should be aware of.

According to OSHA, between 35,000-62,000 injuries occur every year involving forklifts. Furthermore, overturned forklifts account for 25% of all forklift accidents.

Why do forklifts overturn so much? One of the main reasons is due to exceeding lifting capacities and unbalanced loads. And if you are using a forklift boom (or any front-end attachment), that added weight increases the chance of it tipping over.

While forklift booms offer many benefits, including diverse design options and affordable costs, they can also increase the chance of bodily injuries and costly equipment damage if not used properly.

Whether it’s a warehouse or a steel mill, how can you safely use forklift booms at your job site? Our article will cover four tips you can follow, including:

- Reaching out to your forklift manufacturer

- Properly tying back your forklift booms

- Not exceeding rated capacities

- Properly training your workers to use forklift booms

- What Industry Standards Govern Forklift Booms

How Do You Safely Use a Forklift Boom?

1. Reach Out to Your Forklift Manufacturer

The biggest myth with forklift booms is that you can throw them on any forklift and start lifting loads. Not only is this false, but it’s also incredibly dangerous. As mentioned earlier, forklifts are susceptible to overturning, and forklift booms increase this threat.

When adding a forklift boom, the longer it is, the higher the chance your forklift has of tipping over.

Contact the forklift manufacturers to make sure your forklift is large enough to handle the added weight of a forklift boom. Before attaching one to your forklift, the manufacturer must also provide the rated capacity for the boom and the lift truck combined.

You should get approval from them to make sure that the forklift can do the work. Additionally, it may be best practice to request written approval from the manufacturer.

2. Properly Tie Back Your Forklift Booms

One of the most important aspects of using a forklift boom is ensuring it’s tied properly to the forklift’s mast. If not tied properly, the boom can easily slide off the forks.

Safety ties come in various sizes and shapes, including chains, clamps, and nylon slings. The boom should always be positioned on the back of the forks.

When tying down your forklift boom, make sure to level the forklift before loading it and to never tie it down from the front of the boom. It is ultimately on you to use the proper tie-down device for your forklift boom, so reach out to your forklift boom and forklift manufacturer to get their recommendations.

3. Do Not Exceed Rated Capacities

One of the downsides of using a forklift boom is their limited capacity, maxing out at around 4 tons. Overloading your forklift is the easiest way for you to tip it over, so always pay attention to the rated capacity.

All forklift booms should have a visible product identification tag on them, which includes their lifting capacity. Do not use a forklift boom that doesn’t have one.

It’s also important to remember that the longer your forklift boom is, the lower the capacity will be. For example, a forklift boom 6 feet in length will have a 6,000-pound capacity. But if we take it all the way out to 12 feet, it only has a 2,500-pound capacity.

4. Properly Train Your Workers

While forklift booms make your forklift function like a mobile crane, your workers do not need to be licensed crane operators to use them.

This lack of oversight can create scenarios where people who aren’t familiar with forklift booms can cause serious accidents and costly property damage. Especially in more compact environments, like warehouses, this can be catastrophic to your operations.

Having any front-end attachment on your forklift limits its mobility, so extra caution is needed when using one.

When assessing who should operate a forklift boom, ask your workers if they have any experience using one or other front-end attachments. Some best operating practices to follow include:

- Confirm the load’s center of gravity is equal with the hoist’s center of gravity for single-hooks lifts, and the center of each hook for double-hook lifts

- Know the recommended load limit of your forklift with the forklift boom attached

- Verify the unloading area is clear of debris and people

- Avoid double-tiered loads

- Use only approved hooks that came with the forklift boom

If working in outdoor environments, be cautious of mud or ice, as forklifts are susceptible to sliding.

Bonus Tip: Follow Industry Standards

As mentioned in our previous article, forklift booms fall under OSHA standards as industrial trucks. Specifically, OSHA 1910.178 states that:

“If the truck is equipped with front-end attachments other than factory installed attachments, the user shall request that the truck be marked to identify the attachments and show the approximate weight of the truck and attachment combination at maximum elevation with load laterally centered.”

For further guidance, consult ANSI / ITSDF B56.10-2006, which says:

“No modification or alterations to a powered industrial truck that may affect the capacity, stability or safe operation of the truck, shall be made without the prior written approval of the original truck manufacturer or its successor thereof.”

Are Forklift Booms A Good Fit for Your Organization?

When following best safety practices, forklift booms are both an affordable and versatile tool to have at your job site. But it’s important to remember that adding any type of front-end attachment will decrease your forklift’s mobility and increase the chance of them overturning.

As best practice, reach out to your forklift manufacturer to see if your forklift can handle an added boom attachment. Furthermore, always consult industry standards and make sure only qualified and trained professionals are operating them.

To find out more about forklift booms, their ideal applications, and their positives and negatives, read our previous article. If you need more information or want to speak with an expert, contact one of Mazzella’s Below-The-Hook Specialists.