Elebia Hooks in Steel Mills: What They Do and How They Deter Dangers

With hands-free environments becoming popular at steel mills, elebia automatic crane hood are becoming increasingly popular. To help you stay on top of industry standards, our article will cover what an elebia hook is, where they're used in steel mills, their role in improving employee safety, and how they speed up your operations.

For much of the twentieth century, steel mills were one of the most dangerous environments a worker could be in. According to reports from the Bureau of Labor Statistics, the fatality rate of steel and iron workers in 1907 was 220 per 100,000 workers.

Fast forward to 2019, and the rate fell to 26.3 per 100,000, a 90% decrease.

The steel industry has dramatically changed, and employee safety is one of the areas that has improved the most.

Even with this progress, workers still encounter many hazards in a steel mill, like high temperatures, falling from heights, contact with machinery, pinch points, swinging loads, and more.

Recently, steel mills have prioritized implementing a no-touch rigging environment at their facilities—where you can make hands-free connections and keep workers out of harm’s way.

At Mazzella, we have decades of experience providing steel mills with state-of-the-art lifting and rigging equipment, and one of our most popular no-touch technology offerings is the Elebia auto hook.

If you’re looking to install no-touch procedures at your steel mill and are curious about Elebia hooks, this article will answer questions you may have, such as:

- What is an Elebia hook?

- How and where are Elebia hooks used in steel mills?

- Can Elebia hooks withstand a steel mill’s harsh environment?

- Are Elebia hooks a good fit for your hot metal applications?

What is an Elebia Hook?

The Elebia auto hook is a lithium ion battery-powered, automatic crane hook that allows for the remote attachment and release of loads.

One of the more unique features of the Elebia hooks is the attached magnet, which eliminates the need for employees to manually line up bales or rings before closing them.

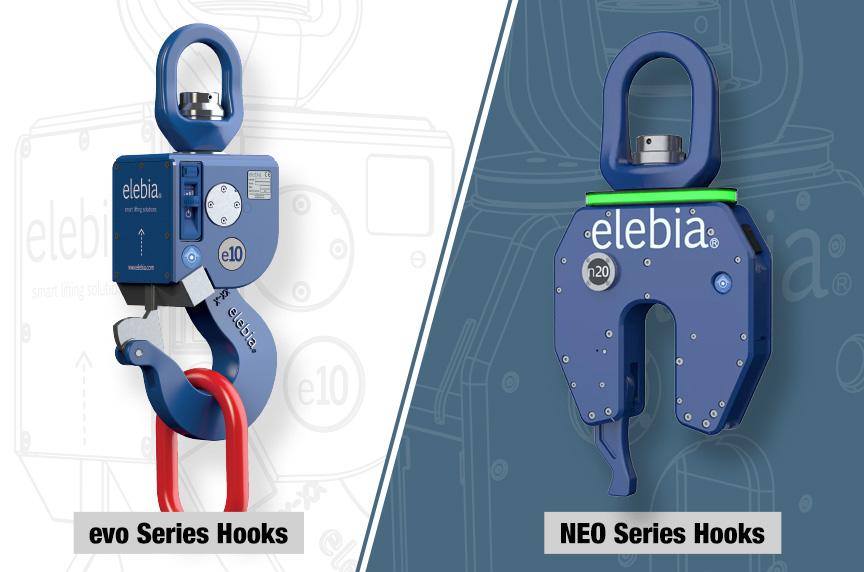

There are two Elebia hook models: the Evo and Neo lines. The Evo model has a lifting capacity ranging from 2.5- to 25-tons. It also utilizes an open swing-style hook with an attached magnet, making it great for lifting chain slings off the ground.

With the Neo model, the lifting capacity range is from 20- to 100-tons, making it ideal for heavy lifting applications, like spreader beams and furnace components. The Neo model also uses a motor-controlled hatch to secure the hook in place.

Historically used in ports and shipyards, Elebia hooks were designed to operate in intense environments, allowing for a seamless transition into steel mills.

How and Where are Elebia Hooks Used in Steel Mills?

Whether it’s the melt shop, hot mills, pickling lines, roll mills, pig lines, or shipping, Elebia hooks are now found in every stage of the steelmaking process.

One of the biggest responsibilities of an Elebia hook is the transportation and handling of graphite electrodes.

These electrodes can weigh several tons, making it impossible for workers to lift them manually. As the conductor for the steel’s furnaces, they’re also incredibly hot, posing a safety risk to workers. And while lifting slings are an affordable and flexible lifting device, they are not designed to withstand the intense environments of a steel mill.

Thanks to their versatility, Elebia hooks make rigging electrodes faster, regardless of whether it’s in a vertical or horizontal position. The hook’s remote control feature eliminates employees needing to climb on top of furnaces to rig them, decreasing their chances of injury.

Another key use of Elebia hooks is along the mill’s pickling line. Before, operators had to crawl into the pickling basket to make a connection for the crane hook, leaving them vulnerable to slip and fall hazards, cuts and abrasions, and exposure to dangerous chemicals. Now, the process can be done completely hands-free.

Furthermore, Elebia hooks can also be used for lifting and rigging:

- Furnace components

- Offloading raw materials

- Tundish and scrap buckets

- Aluminum beams

- Heavy bags

How do Elebia Hooks Deter Danger in Steel Mills?

The Elebia hook was built with safety in mind, and the most significant safety features include:

1. Hands-Free Lifts

Broken hands and feet, soft tissue damage, back pain, and knee and joint issues are some of the most common injuries that can occur when your workers are lifting and moving heavy objects. Thanks to the Elebia hook’s remote control options, operators can now lift loads from over 450 feet away, eliminating repetitive and grueling manual labor.

For example, instead of a worker climbing on top of a hot furnace to hook a graphite electrode, a skilled crane operator can safely do it from the other side of the room.

2. Fail-Safe Technology

Once a hook is loaded with anything weighing 50 pounds or more, the motor’s torque won’t be powerful enough to open it, making it impossible to drop a load when suspended. This feature reduces the chance of damaging your load and protects workers from falling debris.

3. Security Torque Limit (STL)

Built into all Elebia hooks, the Security Torque Limit is a device that detects if a hook is overloaded. If detected, the hook will automatically cancel the operation.

4. Customization Offerings

Elebia offers a variety of customization options for your automatic hook. Some of these include:

- An LED light system with three color stages: blue for “ready to lift,” red for “not prepared to lift,” and green for “ready to engage,” offering operators a better visual line of sight

- A custom shank to fit the hook into your crane block

- A stainless-steel shield for added heat resistance

- Protective bumpers

Can Elebia Hooks Withstand a Steel Mill’s Harsh Environment?

Elebia hooks were designed to function in intense environments. When talking to our lifting and rigging experts, they cited Elebia hooks with three million cycles (which is when the hook opens and closes) without a single mechanical failure. In fact, they haven’t seen one yet that has reached the end of its life cycle.

Furthermore, the batteries have a lifespan of about two years and take less than three hours to fully charge—both exceptional by industry standards. If your Elebia hook has the LED light attachment, a white light will appear when your battery needs to be charged.

Elebia hooks are also made with a trade secret abrasion-resistant steel, allowing the hook to withstand temperatures as high as 482° F. This makes them a great tool to use around the mill’s furnaces. The biggest concern would be your battery, and even then, it can operate in temperatures up to 450° F.

Despite their exceptional durability, ASME B30.20 standards require that all below-the-hook lifting devices, including Elebia hooks, get an annual service check. If you’re working with Mazzella, you would ship the hook back to us. From there, we:

- Fully disassemble the hook

- Check the moving and loading components and make any replacements

- Conduct a reload test before sending it back

With proper maintenance, an Elebia hook can continue operating and withstand a steel mill’s harsh environments for years.

Are Elebia Hooks a Good Fit for Your Hot Metal Application?

Whether it’s removing your workers from dangerous situations, their high durability, or improving productivity levels, Elebia hooks have proven to be a reliable and valuable tool at steel mills nationwide.

With the steel industry moving towards no-touch processes, the Elebia hook is a tool that can make that transition an easy one for your organization.

If you’d like to learn more about Mazzella’s No Touch® technology for steel mills, download this brochure covering our electrode handling systems.

Below-the-Hook Lifting Devices

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

Copyright 2024. Mazzella Companies.