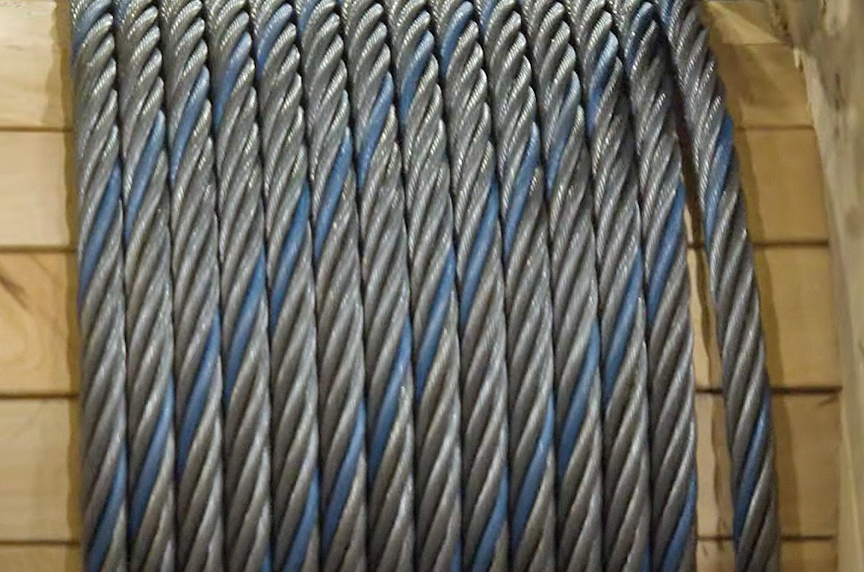

How Can I Identify Domestic Wire Rope Brands by Color Strand?

How can I differentiate between domestic wire rope manufacturers? In the 1980s, U.S. wire rope manufacturers decided to color one of the strands of their products for easier identification among customers.

As an operations manager in need of new ropes, your machines require a specific manufacturer of wire ropes. However, when you walk into a supplier’s warehouse, you don’t know how to identify one wire rope manufacturer’s product from another.

You did notice that domestic wire ropes have different color strands, and those are known as “identifiers.”

To distinguish themselves from international products, domestic wire rope manufacturers selected certain colors to put on their strands.

Although you notice these colors, you’re not sure which company is represented by what color, and we’re here to clear up that confusion.

In this article, we’re going to learn about:

- The different types of strand markers

- Why color coding is used in the U.S.

- How a strand identifier differs from a core marker

- The colors representing major U.S. wire rope manufacturers

Different Types of Strand Markers

With domestic wire rope brands, the way to identify the color strand is by looking at it. This is for general purpose wire rope only, which includes the 6×19 and 6×36 classes.

General purpose wire rope is used in the manufacture of wire rope slings, on overhead cranes, and mobile cranes. It differs from high-performance crane rope. General purpose wire rope isn’t 19-strand or 35×7.

One or two of those strands would have a color marking, which would then identify that wire rope manufacturer.

Why Is Color Coding Used in the U.S.?

Beginning in the 1980s, U.S. companies used color-coding systems as a form of identification to differentiate from international products. This was done to establish traceability as non-domestic manufacturers became more prominent in the wire rope industry.

Typically, using the wire rope will wear off the color strand markers where they’re no longer visible. However, this system is utilized by end-users at the time of receipt to make sure they’re getting the brand of wire rope they ordered.

How Does a Strand Identifier Differ from a Core Marker?

The core marker is different than a strand identifier. The core marker is an internal plastic mono filament film that would help identify:

- Country of origin

- Rope brand (Manufacturer)

Generally, you have to cut into the rope to find the core marker. In the event of a rope failure, the core marker will make it easier to identify the manufacturer. Core markers run throughout the entire wire rope. If you took a cross section of the rope, and deconstructed it, you’d find the film used to identify the manufacturer and country of origin.

Predominantly, domestic wire rope suppliers brought this to market. However, today, most manufacturers, including high quality non-domestic wire rope suppliers, also use internal core markers to identify themselves.

Also, some non-domestic manufacturers have adopted the color strand system.

“The Big Three”

There are three major U.S. Wire Rope manufacturers, including:

The Bridon-Bekaert Ropes Group consists of the Bridon Group and Wire Rope Industries (WRI).

Color Identifications

When it comes to the three major domestic wire rope suppliers and the color strand that identifies them, the markings unique to the brand include:

- Bridon-Bekaert is one blue strand that is going on its general purpose rope

- Wirerope Works has one purple strand to identify its general purpose rope

- WireCo differentiates its color stranding by what wire rope it is

o Their 6×19 wire rope has a red identifier

o The 6×36 class wire rope has a yellow identifier

This helps not only to identify them as the wire rope manufacturer, but also, it acknowledges the class of rope it is.

No Standards of Governance

There are no standards from the American Society of Mechanical Engineers (ASME) or Occupational Safety and Health Administration (OSHA) mandating the use of color strand identifiers.

Simply put, it was an easy way for manufacturers to separate themselves from import manufacturers.

Also, it’s not a hard and fast rule that every run of domestic rope has a color strand. There may be a specific reason that a run of rope doesn’t have a color. Colors are solely based on the manufacturers of the wire rope, and it’s traceability.

Colors don’t identify the wire rope’s working load limit.

This is all about marketing, so customers can identify the manufacturers quickly. The color-coding system was designed so anyone with knowledge of the colors can walk into a warehouse and figure out which suppliers that distributor offers.

Also, customers can identify the wire rope after purchase before it gets put into use.

Making Your Choice

By reading this article, you now know the history and reasoning behind the domestic wire rope color-coding system. Also, you understand which colors represent what domestic wire rope manufacturers.

Having this knowledge should clear up confusion the next time you need wire rope. Hopefully, it will make your buying experience more efficient and user-friendly.

Remember, the color strands are simply identifiers. They are not indications of working load limits. For that information, refer to the manufacturer’s standards, or tags required by ASME.

Call us at 800.362.4601 or click here to get the high performance wire ropes you need!

Crane Ropes

Mazzella stocks a large inventory of high performance wire ropes available for immediate delivery.

We stock our various high performance ropes at our many locations in sizes from 1/4” to 3” diameter and 9 mm to 52 mm diameter.

We stock both domestic and non-domestic products ready for same or next day shipment from one of our many service centers.

Copyright 2021. Mazzella Companies.