What Is Load Securement, and What Standards Govern Safe Transport?

Are you new to the transport industry and need to know how to safely secure your loads before your first trip? Load securement is critical, and the North American Cargo Securement Standard has outlined how to properly tie down the items you are transporting.

Whether it is a bridge crane, steel rods, logs, heavy equipment, another piece of machinery, or building materials, before they can be installed on-site for their working purposes, they must be transported from the manufacturer to the end-user’s facility or worksite.

In order to transport and deliver cargo safely, drivers must have a way to adequately secure the load to the vehicle. Load securement plays a vital role in not only delivering loads safely, but also, keeping America’s public highways free from incidents that could lead to lost loads, accidents with other vehicles, and most importantly, loss of life.

This is why the North American Cargo Securement Standard was created by the U.S. Federal Motor Carrier Safety Administration (FMCSA).

After reading this article, you’ll be able to:

- Specify when North American Cargo Securement Standard applies

- List the three methods of load securement on a motor vehicle

- Define working load limit (WLL) and aggregate working load limit (AWLL)

- Describe how the number of tie-downs required to secure a load is determined

- List safety guidelines related to cargo securement

- Identify when vehicles and load securement devices should be inspected during transport

- List commodities that have special load securement requirements

What is the North American Cargo Securement Standard?

The North American Cargo Securement Standard provides the basis for the rules and regulations covering load securement in the United States and Canada.

This standard was created because unsecured or under-secured loads can lead to:

- Loss of life

- Loss of load

- Cargo damage

- Vehicle damage

- Accidents with other vehicles

The standard applies to all motor vehicles which use public highways and have a gross vehicle weight of over 4,500 kg, or 10,000 lbs.

What is the Purpose of Load Securement Rules?

Load securement rules and regulations were established under the North American Cargo Securement Standard. These rules were created for and ensure cargo does not:

- Leak or spill

- Blow, fall or otherwise dislodge from the vehicle

- Fall through the vehicle

- Shift in a way that adversely affects the vehicle’s stability or maneuverability

In order to avoid any of the above situations, load securement systems have minimum force, requirements in all directions, including forward, rearward, sideways, and sometimes, upwards.

What Are the Ways Cargo Can Be Secured for Transport?

There are three main ways cargo can be secured for transport.

These options include:

- Secured on a vehicle-The cargo must be secured by tie-downs, which can be accompanied by:

- Blocking

- Bracing

- Friction mats

- Other cargo

- Dunnage

- Combination of the above options

- Immobilized-The cargo can be immobilized by structures or a combination of the following:

- Structure

- Blocking

- Bracing

- Fully contained-In this case, the cargo must not be able to shift or tip, and it must be restrained from sideways movement either by other cargo or a vehicle structure.

What Is a Tie-Down?

A tie-down is an assembly of devices that uses one or more anchor points and restricts cargo movement. Several different materials can be used to tie-down a load for transport. They include:

- Chain

- Synthetic webbing

- Wire rope

- Steel strapping

Several other components can used as tie-downs in load securement:

- Clamps

- Hooks

- Winches

- Ratchets

In all cases, the vehicle operator must be able to tighten the tie-downs, except for steel strapping. All of the tie-down components, anchor points, and vehicle structures must be appropriate for the load and in good working condition.

Also, all materials used as chocks, cradles, dunnage, blocking, and bracing must be able to withstand the forces of the load and the tie-downs.

If rub rails are present and the cargo is positioned within them, the tie-downs must be positioned within the rub rails. If the cargo has edges that could cut or tear the tie-down material, edge protection is required.

What Determines a Tie-Down’s Working Load Limit?

The Working Load Limit (WLL) of a securement device is the maximum load that device can handle during normal use.

The working load limit of each tie-down is equal to the lowest working load limit amongst its components, including the:

- Tie-down material

- Connectors

- Tightening devices

- Anchor points

It is important to know that many nylon straps do not indicate their working load limits. They only indicate the breaking strength. For nylon straps, the working load limit is only 1/3 of the breaking strength.

Most tie-down devices are marked with their working load limit or a code or symbol that corresponds to a working load limit. If the tie-down material is unmarked, working load limits for some common materials can be found in the North American Cargo Securement Standard.

The aggregate working load limit, or AWLL, is the combined working load limit of all of the tie-downs and other restraint devices that are used to secure a particular load.

According to United States Department of Transportation standards, the AWLL for indirect tie-downs should be at least half of the cargo’s weight for general freight securement. For direct tie-downs, the AWLL must be at least equal to the cargo’s weight.

What Are the Methods of Load Securement?

There are two types of tie-downs used when securing loads to transport vehicles, and they are direct tie-downs and indirect tie-downs.

A direct tie-down connects to an anchor point on the vehicle and to the cargo. Ideally, the tie-down angle should be less than 45° from horizontal.

An indirect tie-down passes through, over, or around the cargo, and is connected to two anchor points on the vehicle.

For tie-downs that pass over the cargo, the angle should be greater than 45° to maximize the downward force on the cargo.

Different tie-downs contribute differently to the aggregate working load limit. A direct tie-down or indirect tie-down with anchor points on the same side of the vehicle contributes only half of its working load limit, while an indirect tie-down with anchor points on opposite sides of the vehicle contributes to its entire working load limit.

How Many Tie-Downs Are Required for Safe Load Securement?

Basic load securement rules require the aggregate working load limit be equal to or greater than half the cargo weight.

Example: To secure a 20,000 lb. load for transport, the aggregate working load limit of the tie-downs and other securement devices should be at least 10,000 lbs. If blocking or friction mats are used, the aggregate should also include those components.

The required number of tie-downs also depends on the cargo’s length. The basic rule is that if forward restraint is present, there should be one tie-down for every 10’ or 3 m of cargo length. If forward restraint is not present, an additional tie-down is required.

According to the U.S. Department of Transportation, the bare minimum for a general freight load that has a length of 5’ and weighs 1,100 lbs. is one tie-down. Then, a load measuring 10’ in length and less than 10,000 lbs. requires a minimum of two tie-downs. Loads heavier than 10,000 lbs. require four tie-downs, and one additional tie-down per 10’ of load length.

It is often said “you can never have enough tie-downs.” While this is basically true, if damaged tie-downs are used, even if the undamaged tie-downs meet or exceed the aggregate working load limit requirement, the driver still can be cited.

Therefore, it is a good idea to:

- Examine tie-downs on a regular basis

- Discard damaged or worn-out devices

- Replace the compromised devices with good ones

For some commodities, including logs, lumber, wire coils and paper rolls, more detailed requirements are specified in the North American Cargo Securement Standard.

What Safety Guidelines Should Be Followed When Loading Cargo?

Before loading cargo, you need to make sure all personnel are:

- Wearing or using the proper personal protective equipment (PPE) for the job. If mobile equipment is being moved onto a trailer, this includes the operator wearing a seatbelt.

- If heavy equipment or machinery is being moved, make sure the equipment is clean and free of loose debris that could come loose during transport, including:

- Rocks

- Dirt

- Mud

3. Know the laws and regulations for every jurisdiction through which you will travel.

4. Don’t hurry and don’t take shortcuts-Take the time to think about what you’re doing and the consequences.

What Are the Safe Loading Steps?

The four steps that are critical to safe loading of large or heavy loads are:

- Measure

- Load

- Re-measure

- Secure

Performing these steps each time before transporting a load will help prevent:

- Accidents

- Equipment damage

- Injuries during:

- Loading

- Transporting

- Unloading

It is important to determine the height, width, and weight of the cargo before it is loaded. For heavy equipment, this information usually can be found in equipment manuals.

These measurements are used to determine the required number and type of load-restraint devices, and whether the load meets all of the relevant rules and regulations for transport. Also, inspect the vehicle structures, chains, straps, connectors, and other devices that you will be using the secure the load.

If any of the load securement items are damaged, or are not rated properly for the load, they must be replaced before transport.

How Do I Safely Load Wheeled or Tracked Equipment?

Once the cargo has been measured and the vehicle and securement devices have been checked, it is time to load the equipment.

If wheeled or tracked equipment is being loaded:

- Make sure the operator of the equipment is experienced and familiar with the machine and the controls

- Make sure a spotter is present at a safe distance and the spotter stays visible to the operator during loading

- Once loaded, lower all implements, secure the steering lock and any swing-frame locks, and follow all other instructions listed in the manual

- Make sure at least 50 percent of the outside tire or track width is supported by a vehicle structure

***For wheeled and tracked equipment, the USDOT requires a MINIMUM of four tie-downs for safe load securement. Also, any piece of equipment over 10,000 lbs. will require four tie-downs, each with a WLL of 5,000 lbs.

Load Positioning and Re-Measuring

When the cargo has been moved onto the trailer, make sure the load is balanced, front to back and left to right, and is properly positioned over the axles. Also, measure the height and width of the load, including all attachments on heavy equipment.

Securing the Load

Once the cargo is loaded, it is time to secure it for transport, and you should follow these steps to make sure you are as safe as possible during travel:

- Be aware of all regulations regarding:

- Number of tie-down points

- Allowable chain, strap or wire rope sizes

- Type and number of tightening devices

- Remember to consult with local experts if you have questions or are unsure about anything

- Remember only use designated tie-down points, and to lower and secure all:

- Attachments

- Buckets

- Work tools on heavy equipment

- Use proper grade chains, straps, or wire ropes with the proper load rating for the cargo being secured

- Tighten all chains, straps, or wire ropes until they are straight and tight. Be careful not to over-tighten, as this can strain and weaken the tie-down components

- If the load is wide:

- Use flags

- Make sure the load does not interfere with the driver’s view of the road

- Inspect cargo and restraint devices within the first 50 miles of the trip

- After the first inspection, re-examine securement at regular intervals, including:

- Three hours

- 150 miles

- New driver

What Is Commodity-Specific Securement?

Several commodities have specific requirements for their transporting, including:

- Logs

- Lumber

- Metal coils

- Paper rolls

- Concrete pipe

- Automobiles

- Light trucks

- Vans

- Heavy vehicles, equipment and machinery

- Large boulders

Examples of special requirements include:

- Blocking for cargo that can roll

- Special vehicle structures

- For logs, those would include:

- Bunks

- Bolsters

- Stakes

- For logs, those would include:

- Specific stacking and arrangement details for lumber, paper rolls, and concrete

What Training Should Companies Give their Employees?

The most important factor is abiding by the load securement standards of the North American Cargo Securement Standard and Federal Motor Carrier Safety Administration (FMCSA). Training should occur with any operator prior to performing the load securement, to ensure proper selection, inspection, and use of the equipment.

Example: Mazzella utilizes computer-based training to help in reviewing load securement covering the North American Cargo Securement Standard and FMCSA requirements. After that, it is important to confirm competency with the operator and demonstrate what success looks like for the specific vehicle that will be used.

While many people can pass an online quiz or course, operators need to apply those lessons in real-world settings. Supervisors are required to observe operators, and utilize ride-alongs to confirm they are:

- Doing their pre-use inspection

- Securing their loads and making sure they’re taut

- Making the requisite stops (miles / minutes) to reassess the loads. During the assessments, the focus is on looking at each of the tie-downs to make sure they’re secure.

How Can Mazzella Help You with Load Securement?

Load securement rules and regulations help ensure the safety of drivers and passengers on public highways.

If you are involved in the transport of large or heavy cargo on motor vehicles, make sure you are aware of all rules and regulations for the cargo being transported and the jurisdictions you will be driving through. If you have any questions or concerns, it is recommended that you consult with a local expert to get the proper answer or solution to any issues.

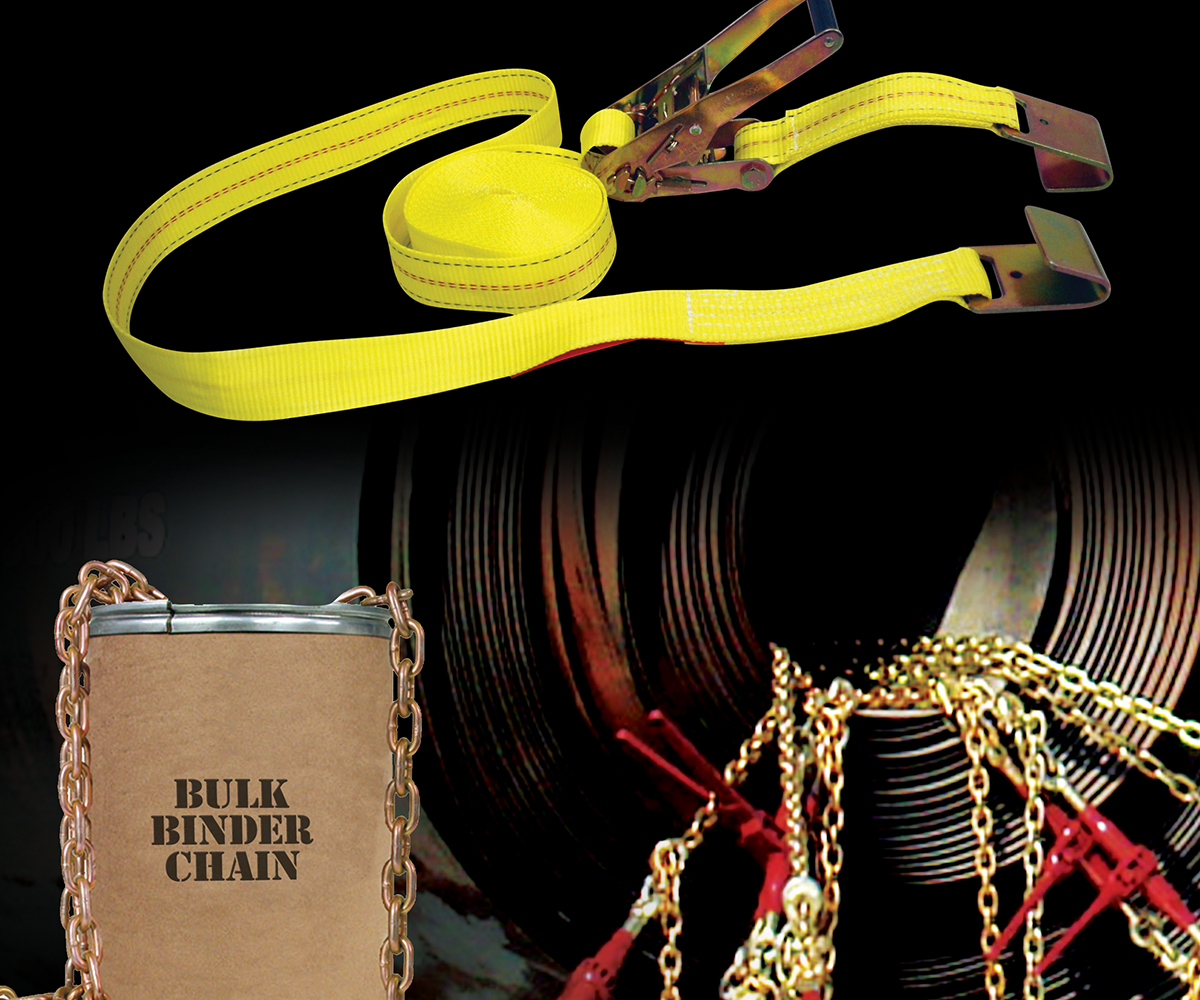

We stock an entire line of load securement products to secure your loads to your trucks and trailers.

Mazzella stocks binder chains, load binders, ratchet straps and truck tie-down assemblies, along with a complete line of alloy and carbon chain, and fittings.

Not only do we offer a competitive price, but you can also depend on our quality service and selection. If you have a question or need advice, our Lifting Specialists are an excellent source for information.

Call us at 800.362.4601 or click here if you need load securement products!

Load Securement

Do you need to ensure your cargo is safely secured during transport? We stock an entire line of load securement products to secure your loads to your trucks and trailers.

We stock binder chains, load binders, ratchet straps and truck tie-down assemblies, along with a complete line of alloy and carbon chain, and fittings.

Copyright 2022. Mazzella Companies.