A Buyer’s Guide to Selecting a Fall Protection Harness

Working at height is a dangerous business, but the risks for injury / death can be greatly reduced by using fall protection equipment. Selecting the proper fall protection harness is a good place to start, and here is a buyer’s guide for selecting the correct one for your needs.

If you’re new to the construction or manufacturing industries, you may be wondering how to protect yourself while working at height. Selecting the correct harness is a good place to start, and it is important to consider comfort, fit, unique features, and what you will be doing while at height to make the best possible choice.

Harnesses are a critical piece of “personal fall protection,” and full-body harnesses are approved for use in:

- Fall arrest

- Positioning

- Confined space rescue

- Ladder climbing devices

It is key to keep harnesses in proper working condition because doing so could be the difference between making it home safely after completing a day’s work, and not making it home at all due to a failure in personal fall protection equipment leading to injury or death.

However, before you can keep a harness in working condition, you must first select the proper fall protection equipment for working at height.

In this article, we will look at the following, which will help in your search for a fall protection harness:

- What material should your harness be made from

- Where should the D-rings be located?

- Selecting a harness for your body type

- Making a checklist for the manufacturer

What Material Should Your Harness Be Made From?

A typical harness is going to be made out of polyester straps. However, it might be Kevlar if you’ll be working around welding or in another kind of hot environment. The Kevlar harness is able to adapt and withstand those higher temperatures, or those demands on your environment.

For workers who perform several tasks while they’re at height, or frequently change working environments, that needs to be taken into consideration. You might need two different types of harnesses just for that reason. However, some manufacturers have a product that will be able to be worn in multiple environments.

Where Should Your D-rings Be Located?

The location of the D-rings is another factor that must be considered before selecting a harness for your at-height work, and much of it will be determined by the type of lifeline you’re using.

There are two types of D-rings:

- Sternum D-rings

- Dorsal D-rings

Sternum D-rings are located on the chest, and if you’re using a vertical lifeline, that would be your best option. It will eliminate any interference that would be present with a dorsal D-ring.

For horizontal lifelines, you need the dorsal D-ring as to not interfere with what you’re doing in the field. Iron workers commonly use horizontal lifelines and dorsal D-rings.

Additionally, there are harnesses with side D-rings, but those are used for positioning, and not as anchor points. Side D-rings are used for you to position into what you’re doing, so you can have both hands free. Most of the time, workers using side D-rings are connected to a vertical lifeline.

Selecting a Harness for Your Body Type

Everybody’s body type is different, and thus, their fall protection equipment must be customized to their needs.

Body type really refers to your range of motion. Some people have longer arms, while others are taller than the average worker. It’s going to affect how you actually do your job while you’re working at height.

You may ask, “Is comfort important? Are the features important?”

The answer to both questions is yes because the fall protection harness has to fit your body for best results in the event of a fall. The harness has to do what you need it to do in case you experience a fall. When you’re fitting that harness, it has to fit as if it were custom-made for your body. Many manufacturers have harnesses that can adjust to your body.

While the specification on harnesses in OSHA 1910.140 is 310 pounds of total weight (worker and tools), there are harnesses specially made for a higher weight requirement.

***OSHA 1910.140 is a standard used by the Occupational Safety and Health Administration, who is responsible for investigating any incidents that result in serious injury and / or death on the job site.

Make a Checklist for the Manufacturer

Manufacturers will help you select the harness needed for you to work safety while at height, but to get the one that best suits your needs, you should be prepared with a list of topics to discuss with them. Those topics should include at least the following:

- What type of work you do?

- Are you in construction or general industry?

- Are you going to be doing several different tasks while working at height?

- Are you going to be welding?

- Are you going to be using it while pipe fitting or something that is unique to your work environment?

After taking these factors into consideration, the manufacturer will select what they would recommend as the best harness for your needs, and explain their reasoning for choosing that piece of fall protection equipment. Getting as much information before you actually select the harness is really the best course of action. You should always refer to the manufacturer specifications and recommendations before selecting your harness.

You want to be as detailed as possible when shopping for a harness as to get the one that best suits the type of work you will be doing at height and the environment in which you ply your trade. By making your own checklist, you’re essentially saying to yourself, “Hey, there are companies that have been in the business for a while, and they can help you.”

How Can Mazzella Help With Your Fall Protection Needs?

Accidents while working at height are one of the biggest causes of workplace injury and death. You need to make sure you are doing things safely and correctly. We can help with your fall protection needs, plans, equipment, and training.

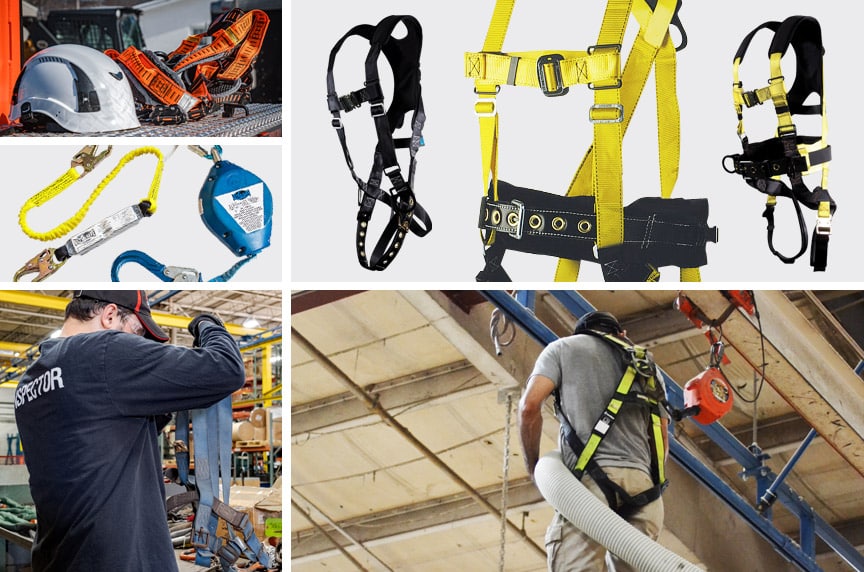

Mazzella has custom-configured several types of fall protection systems for businesses across the country that have diverse needs based on their working conditions. Also, we are a distributor of The XSERIES Mobile Grabber® fall protection units and have helped several customers select and use this equipment in the field.

Mazzella is a leading supplier and installer of engineered fall protection systems in the U.S., as well as a distributor of soft goods, including harnesses, lanyards, self-retracting lifelines, scaffolding and netting. All of our engineered systems and products meet or exceed the federal criteria required by OSHA and ANSI (the American National Standards Institute) and can be customized with your individual fall protection and financial needs in mind.

We work with our partners to provide full-body harnesses, as well as many other fall protection products.

Also Mazzella specializes in site analysis and evaluation, as well as employee training for equipment installed or products sold. Also, we offer general training, system inspection, documentation storage, and procedure development, like rescue plans.

Rigging inspections are what Mazzella is known for. However, personal fall protection inspections pair well with our rigging inspections division.

What our rigging inspectors have found over the years is that while looking at all the rigging in a facility, many of the workers using this rigging also use personal fall protection. Through our personal fall protection inspection training, we are competent to conduct these inspections.

Call us at 800.362.4601 or click here if you need harnesses or other fall protection equipment!

Fall Protection

We are a leading supplier and installer of engineered fall protection systems in the U.S., as well as a distributor of soft goods like harnesses, lanyards, self-retracting lifelines, scaffolding and netting. All of our engineered systems and products meet or exceed the federal criteria required by OSHA and ANSI and can be customized with your individual fall protection and financial needs in mind.

We specialize in site analysis and evaluation, as well as employee training for equipment installed or products sold. We also offer general training, system inspection, documentation storage, and procedure development, like rescue plans.

Copyright 2022. Mazzella Companies.