Synthetic Slings: Web Slings, Roundslings, and Polyester vs. Nylon

If you’re lifting highly finished parts or delicate materials, then a synthetic lifting sling can provide the flexibility, strength, and support you need to support a specialized load. Synthetic slings can be made from polyester, nylon, or high-performance materials and are lightweight, easy to rig, and extremely flexible.

Are you tired of cumbersome lifting slings that are heavy and difficult for your workers to maneuver when rigging a load? Are you concerned that the slings you’re using are marring, scratching, or crushing delicate loads? A synthetic sling may be the best choice for your overhead lift and can provide the flexibility, strength, and support you need to move material through your facility or job site.

However, you’ll have to give special considerations to the operating environment, stretch under load, and the possibility of the load causing cuts or abrasion to the sling.

At Mazzella, we manufacture and distribute all types of lifting slings, as well as rigging hardware, below-the-hook devices, and other lifting products. In this article, our goal is to expose you to:

- The advantages and disadvantages of using synthetic slings

- A comparison between polyester and nylon slings

- A look at the differences between web slings and roundslings

What Is a Synthetic Lifting Sling?

If you’re lifting highly finished parts or delicate materials, then a synthetic lifting sling can provide the flexibility, strength, and support you need to support a specialized load. Synthetic slings can be made from polyester, nylon, or high-performance materials and are lightweight, easy to rig, and extremely flexible.

Synthetic slings are popular in construction and other general industries because they’re fairly inexpensive, come in a variety of standard sizes, and can be replaced easily.

Advantages of Using Synthetic Slings

Because they’re so flexible, they can mold to the shape of delicate and irregularly-shaped loads, or be used in a choker hitch to securely grip loads of round bar stock or tubes. The soft materials they’re made from are strong enough to lift heavy loads, but will protect expensive and delicate loads from scratches and crushing.

Synthetic slings are extremely versatile, can be used in vertical, choker, and basket hitches and have a Design Factor of 5:1, meaning the breaking strength of the sling is five times higher than the rated Working Load Limit (W.L.L). Never exceed the rated Working Load Limit.

- Inexpensive and lightweight design makes them attractive to almost any industry or lifting application

- Made of soft, flexible materials that grip and mold to the shape of irregular loads

- Strong enough to lift heavy loads but will protect expensive and delicate loads from scratching and crushing

- A variety of materials, construction, and specifications can tailor synthetic slings to almost any lifting application

- Constructed from non-sparking and non-conductive fibers, so they can be used in explosive atmospheres

Disadvantages of Using Synthetic Slings

Careful consideration must be given to the application when determining whether or not to use a synthetic lifting sling. They are more susceptible to damage from environmental factors like extreme temperatures, prolonged UV exposure, and chemically active environments. They’re also not as durable as steel wire rope slings or alloy chain slings when it comes to abrasion and cut resistance.

- Synthetic slings have a relatively low heat-resistance and are not recommended for use in high-heat applications. However, special high-heat resistant slings are available from certain manufacturers.

- Special considerations must be made when selecting a synthetic sling to be used in chemical applications. Nylon and polyester slings have different resistance characteristics to acidic and alkaline environments

- Corner protectors or edge guards should be used to protect against cuts and tears

If there’s any evidence of heat damage, UV damage, rips, tears, punctures, abrasion, or worn or broken stitching, the sling should be removed from service and properly disposed of to discourage further use.

Polyester vs. Nylon Lifting Slings

When choosing a material for synthetic sling use, we recommend considering a material’s resistance to specific chemicals, temperature resistance, and stretch. Below we’ll provide some of the considerations and characteristics of a polyester slings vs. a nylon sling to help you make more of an informed decision.

Synthetic Polyester Slings

- Approximately 3% stretch at rated capacity – less bounce allows for more load control during a lift

- Polyester is a softer material and less abrasive to sensitive or delicate finishes on loads

- Lower liquid absorption compared to nylon and is non-conductive

- Resistant to acidic environments and interactions with bleaching agents

- Good for low headroom lifts

- More popular in Europe but becoming more popular in the U.S. as the cost of nylon material continues to rise

- Not recommended for alkaline environments including aldehydes, ethers, and strong alkalis

- Can’t be used in environments in excess of 194°F or below -40°F

Synthetic Nylon Slings

- 8-10% stretch at rated capacity – can help reduce shock loading but stretch must be accounted for in low headroom lifts

- Unaffected by grease and oil

- More popular in the United States and most widely used material for general purpose synthetic web slings

- Resistant to aldehydes, ethers, and strong alkalis

- Not recommended for acidic environments or for use with bleaching agents

- Retains moisture which can add to or cause stretch under load—however moisture does not affect capacity

- Will conduct electricity because they can absorb moisture/water—NEVER bet your life on this!

- Can’t be used in environments in excess of 194°F or below -40°F

See the chart below for guidelines on what type of slings can be used in conjunction with various types of chemicals:

| Nylon | Polyester | |

| Acids | No | * |

| Alcohols | Yes | Yes |

| Aldehydes | Yes | No |

| Strong Alkalis | Yes | ** |

| Bleach Agents | No | Yes |

| Dry Cleaning Solvents | Yes | Yes |

| Ethers | Yes | No |

| Halogenated Hydrocarbons | Yes | Yes |

| Hydrocarbons | Yes | Yes |

| Ketonnes | Yes | Yes |

| Oils (Crude) | Yes | Yes |

| Oils (Lubricating) | Yes | Yes |

| Soaps & Detergents | Yes | Yes |

| Water & Sea Water | Yes | Yes |

| Weak Alkalis | Yes | Yes |

* Disintegrated by concentrated sulfuric acid

** Degraded by strong alkalis at elevated temperatures

Synthetic Web Slings

Web slings are flat belt straps made of webbing material and most commonly feature fittings, or flat or twisted eyes, on each end. Web slings are the most versatile and widely-used multi-purpose sling. They’re strong, easy to rig, and inexpensive. Compared to chain, they’re more flexible and lighter and can be used to help reduce scratching and denting to loads. They can also be fabricated with wide load-bearing surfaces up to 48” to provide significant surface contact for heavy and large loads.

Nylon web sling performance isn’t affected by oil and grease, and they’re resistant to alkaline-based chemicals. However, they should never be used in acidic atmospheres or near chemicals used as bleaching agents. Polyester web slings can be used in acidic environments or near chemicals used as bleaching agents, but should never be used in alkaline environments.

They also have a relatively low heat-resistance and are not to be used in environments that exceed 194°F, or environments where temperatures are below -40°F. For loads with sharp edges, corner protectors or edge guards should be used to protect the sling from cuts and tears. Because there is a difference between abrasion resistant protection and cut resistant protection, be sure to identify the type of resistance required for your application.

If used outdoors, they should be stored away in a cool, dark, and dry environment to avoid prolonged exposure to sunlight and UV rays, which can damage and weaken the strength of the sling. When a lift is made at the W.L.L., the user can expect approximately 8-10% stretch when using a nylon web sling and 3% stretch when using a polyester web sling at rated capacity.

Polyester Roundslings

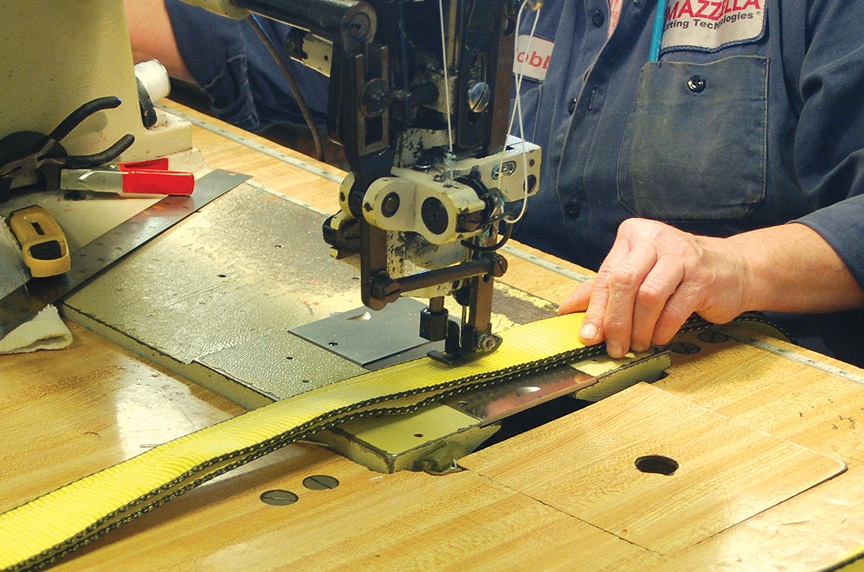

Synthetic roundslings can include both a single path and multi-path design. The multi-path design can consist of high-performance fibers which results in a lighter, more ergonomic, and stronger sling.

Endless roundslings have load-bearing fiber or core yarns that are protected by a single or double woven outer jacket. They are strong, soft and flexible, and protect smooth or polished surfaces from scratches, dents, and crushing.

Roundslings can be used in vertical, basket, or choker hitches—which are especially useful for lifting tubes and pipes. When used in a choker hitch, roundslings release the choke much easier than a web sling would.

While the woven outer jacket has no load-bearing capability, it is designed to protect the internal load-bearing fibers and core yarns against abrasion, dirt and grease, and UV degradation. Polyester roundslings are suitable for acidic environments, or near chemicals used as bleaching agents, but should not be used in alkaline environments.

Like web slings, roundslings are more susceptible to heat damage and should not be used in environments that exceed 194°F or below -40°F. For loads with sharp edges, corner protectors or edge guards should be used to protect the sling from cuts and tears.

If used outdoors, they should be stored in a cool, dark, and dry environment to avoid prolonged exposure to sunlight and UV rays, which can damage and weaken the strength of the sling. When a lift is made at the W.L.L., the user can expect approximately 3-5% stretch when using a roundsling.

Wrapping it Up

When it comes to selecting the right type of synthetic lifting sling for your overhead lift, there are a number of different factors to consider, including:

- Strength and rated capacity of the sling

- Flexibility of the sling

- Resistance to extreme temperatures

- Resistance to abrasion, cuts, or tears

- Resistance to corrosion, chemical exposure, and UV degradation

- Weight of the sling

- Ease of inspection

- Ability to be repaired/proof-tested/re-certified

At Mazzella, we provide rigging inspection services, and rigging/operator training to workers in all types of industries. We have locations scattered throughout the eastern half of the United States that provide specialized lifting and rigging services to industries like energy, construction, automotive, steel, naval and maritime, and mining.

If you have questions about the proper type of lifting sling you should be using for your application, or you want to get better service life out of the slings you’re currently using, contact a Lifting Specialist at a location nearest you.

Slings & Assemblies

Are you looking for lifting slings, including chain, wire rope, synthetic flat web, metal mesh, cordage, and single-path / high-performance roundslings? We can help provide the right sling for your needs!

Additionally, if you need sling assemblies—both large and small, we can manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Contact us today to get the lifting slings and assemblies you need!

Learn more about lifting slings and assemblies!

Copyright 2018. Mazzella Companies.