What are the Most Commonly Serviced Items on Overhead Cranes?

In certain facilities, it’s not uncommon to see a 50-year-old overhead crane still in operation. In other facilities, you will see an overhead crane showing significant wear and problems after just months of operation. Why is that?

Overhead cranes can be one of the biggest long-term investments an organization can make. They can speed up processes, improve employee safety, reduce downtime, and some operations are just not practical to be performed without an overhead crane.

However, like any complex machinery, they require regular maintenance and inspections to ensure they operate safely and effectively. With some overhead cranes costing several hundred thousand dollars, and crane breakdowns often costing thousands of dollars per hour, you can’t afford to have one constantly breaking and not performing to your standards.

Whether you are a crane service professional or responsible for purchasing cranes for your organization, understanding these common problems and their solutions can help you maintain your equipment and avoid costly downtime. This article will explore the most common issues with overhead cranes and provide practical advice on how to prevent them.

Here’s what we’ll go over:

- Common problems with overhead cranes

- Issues with wrong duty cycles

- Wire rope maintenance challenges

- Hoist brake problems

- Control system (radio/pendant) failures

- Hoist gearbox issues

- Runway and rail alignment problems

- How to choose the right overhead crane

What are the Most Common Problems with Overhead Cranes?

According to our overhead crane experts, the most common issues are:

- Cranes are being used in the wrong duty cycle and application — increased strain on key components that can cause a failure

- Neglected Gearboxes — a lack of proper inspections and maintenance in mechanical gearboxes on hoist, trolleys and bridges will often result in leaks, premature wear and failures of these components.

- Overlooked Wire Rope Assemblies — a lack of proper inspection and regular lubrication of wire ropes will lead to premature failures and risk of dropped loads.

- Runways and Rail Alignment Issues — misalignment can cause serious damage to crane wheels, bearings, gearboxes and runway structures.

- Radio and Pendant Control Issues — disrupt crane operations

- Hoist Brake Issues — can lead to load drift, which are dangerous for the load and workers

What are the Common Issues With Wrong Duty Cycle?

The duty cycle is a measure of how often and how intensely a crane is used. It takes into account factors such as the frequency of lifts, the type of load, and the average weight of the loads handled.

There are six (6) different classifications for overhead cranes, specified by the Crane Manufacturers Association of America (CMAA).

Common Issues and Causes

A 25-ton Class C crane is not the same as a 25-ton Class E Process Crane. Using the wrong duty cycle can overstress wire rope, gearboxes, wheels, bearings, motors, and controls, leading to early failure and costly repairs.

Oftentimes, people will choose the wrong crane during the initial purchase phase to save money, and they end up spending more money in the long run making modifications, replacing parts, and fixing breakdowns.

Prevention Tips

Evaluate how frequently and intensely your crane will be used and consider environmental conditions. Speak with your engineering and production teams. A reputable crane manufacturer can guide you through proper crane selection and custom design solutions.

What Are the Common Issues with Wire Ropes?

Wire ropes can be very susceptible due to their exposure to:

- Abrasion

- Stretch

- Diameter reduction

- Corrosion

- Kinks and birdcaging

- Heat damage

- End fitting damage

- Peening, fatigue, and broken wires

Common Issues and Causes

Wire ropes can suffer from various issues, including wear and tear from regular use, damage due to improper use, and corrosion from exposure to harsh environments. Overloading the crane can also lead to premature wear and damage to the wire ropes.

Prevention Tips

To prevent these issues, it is essential to conduct regular inspections of the wire rope. Required monthly inspections and a regular lubrication schedule can identify signs of damage early and prolong the life of the wire rope.

How Can You Keep Hoist Brakes in Top Condition?

Hoist brakes ensure the crane can lift and hold loads securely. Problems include brake pad wear, brake gap issues, and load drift.

Common Issues and Causes

Like the brake pads on your car, they can wear out over time, leading to reduced braking efficiency. Brake gap issues, where the gap between the brake components becomes too large, can also affect the braking performance and cause mechanical failures. Load drift, where the load continues to move after the brake is applied, is another common problem that can indicate brake issues.

Prevention Tips

Inspect regularly. Adjust gaps as needed. Replace pads promptly. Listen for abnormal sounds during use.

Why Are Radios and Pendants Essential for Crane Operations?

Radios and push button pendants are the primary control systems for operating overhead cranes. They allow operators to control the crane’s movements safely and efficiently. However, these control systems can experience issues such as electrical failures and signal interference.

Common Issues and Causes

Electrical failures in radios and pendants can occur due to wear and tear on the components, exposure to harsh environments, or improper handling.

Prevention Tips

To prevent issues with radios and pendants, regular testing and maintenance are essential. Keeping the control systems clean and free from dust and debris can help prevent electrical failures. Ensuring that the control systems are properly designed for crane operations is also key.

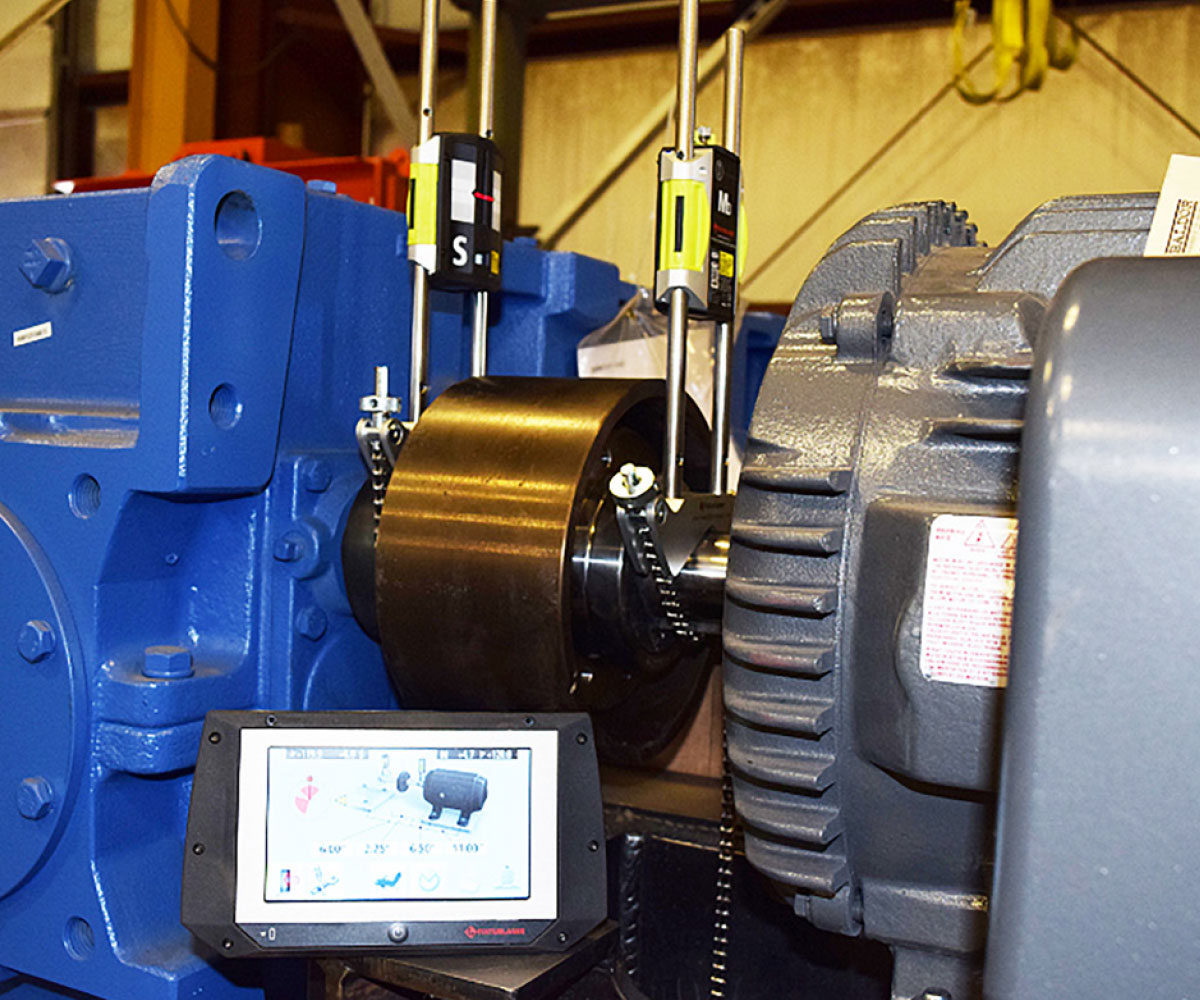

What Should You Know About Maintaining Hoist Gearboxes?

Hoist gearboxes are responsible for transferring power from the motor to the hoist, trolley or bridge components to move the components or load properly, making them a critical component of overhead cranes. However, they can suffer from issues such as oil contamination and gear wear.

Common Issues and Causes

Oil contamination in hoist gearboxes can occur due to a lack of regular oil changes or the ingress of contaminants. Gear wear can result from overloading the crane or excessive use without proper maintenance.

Prevention Tips

Regular oil changes are essential to maintain the performance of all hoist gearboxes. Following the OEM recommendations for oil change intervals can help prevent oil contamination.

Conducting particulate testing of the oil can also help identify contaminants early, allowing for timely maintenance. Additionally, adhering to proper usage guidelines and avoiding overloading the crane can reduce gear wear and extend the lifespan of the gearbox.

How Do You Ensure Runway and Rail Alignment Stays Accurate?

Runway and rail alignment are crucial for the smooth operation of overhead cranes. Misalignment can lead to issues such as wheel wear, bearing failures, and structural problems.

Common Issues and Causes

Improper installation of the runway and rail system can lead to misalignment. Soil compression and settling of the building or foundation over time can also cause alignment issues. Lack of routine checks can allow these problems to go unnoticed until they cause significant damage.

Prevention Tips

Conducting routine runway surveys is essential to ensure accurate alignment. Addressing soil compression and settling issues promptly can prevent misalignment. Ensuring tight tolerance during the installation of the runway and rail system can also reduce the risk of alignment problems. Regular checks and maintenance can help identify and address alignment issues before they lead to more severe problems.

How Can You Choose the Right Overhead Crane?

Don’t Just Look at the Price Tag

For many companies, $300,000 for an overhead crane seems like a very steep price. Why wouldn’t they choose a more affordable option, one in the $25,000-$50,000?

Cheaper cranes may lack OEM or commercially available parts and may not be built for your application. A low upfront cost often leads to higher long-term expenses.

Consider the Entire Lifespan of the Crane

When researching an overhead crane model, it’s common for people to only think about their costs for the next two or three years. In that case, they will opt in for the more affordable option and ignore the true costs of owning an overhead crane.

Consider the entire lifespan of an overhead crane, realizing these are systems that can (and should) last decades.

Make Sure You Have Commercially Available Parts

Crane owners benefit from the flexibility of sourcing parts from multiple suppliers. Relying solely on the OEM can mean inflated costs and limited options.

Final Thoughts

Addressing common issues such as wire rope wear, hoist brake problems, control system failures, gearbox maintenance, and runway alignment can extend the life of your overhead crane by decades.

By implementing regular inspections, adhering to maintenance schedules, operator training, and following best practices for crane operation, you can ensure the safety and efficiency of your overhead cranes and keep them running for generations.

Whether you’re a Production Manager, Safety Officer, or Maintenance Technician, staying ahead of these issues is critical.

Try our free Crane Inspection Price Calculator to get a quick estimate of your service needs in less than 5 minutes.

Calculate Your Crane Inspection Cost.