What is ASME B30.30, and How Does It Apply to Wire Rope Inspection

How do I make sure my wire rope is compliant with the ASME B30.30 standard? Inspecting wire rope is not just a periodic requirement done by an outside company. If you notice something is suspect, you should pull it from service for further evaluation and potential retirement/disposal.

When was the last time your company had their wire rope inspected for potential removal from service criteria?

Wire rope inspection is a vital part of the maintenance process for any construction or crane company because the safety of your workers and security/undamaged delivery of loads lifted by this equipment are of utmost importance.

The guidelines for these inspections comprise the B30.30 Ropes Standard from the American Society of Mechanical Engineers (ASME), and in this piece, you will learn more about the:

- The ASME B30.30 Ropes Standard

- Common problems found on wire rope inspections

- Records keeping

- Recommended disposal criteria

ASME B30.30 Ropes Standard and Types of Crane Wire Rope Inspections

General

***Prior to the ASME B30.30-2019 Ropes standard, there was not an all-inclusive standard that covered steel wire rope and synthetic rope. Typically, rope was addressed in the individual ASME standard for specific equipment such as B30.2 for overhead and gantry cranes or B30.5 for mobile and locomotive cranes, as well as the other B30 standards for additional types of equipment. For now, the reference to wire rope or synthetic ropes contained in those other standards still apply. Our understanding is that as those other standards are updated, they will reference the ASME B30.30 Ropes standard. The intent of this article is to discuss the inspection for steel wire rope as contained in the ASME B30.30-2019.

Outlined in Section 30-1.8.1, “all inspections shall be performed by a designated person. Any deficiencies identified shall be examined and a determination made by a qualified person as to whether they constitute a hazard and, if so, what steps need to be taken to address the hazard.”

In the ASME B30.2 Overhead and Gantry Cranes Standard, a designated person is defined as:

“A person selected or assigned by the employer or the employer’s representatives as being competent to perform specific duties.”

Section 30-0.3 addresses Personnel Competence in this way:

“Persons performing the functions identified in this Volume shall, through education, training, experience, skill, and physical fitness, as necessary, be competent and capable to perform the functions as determined by the employer or employer’s representative.”

OSHA (Occupational Safety and Health Administration) defines a Competent Person as:

“One who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.” (OSHA 29 CFR 1926.32 (f)).

Frequent Inspections

ASME 30-1.8.1 (b) states that:

“Running rope in service shall be visually inspected daily, unless a qualified person determines it should be performed more frequently. The visual inspection shall consist of observation of all rope that can reasonably be expected to be in use during the day’s operations. The inspector should focus on discovering gross damage that may be an immediate hazard.”

According to the B30.30 Standard, inspectors are looking for:

- Distortion of rope structure

- Broken wires

- Corrosion

- Gross damage or deterioration of the end connections

- Evidence of heat, electrical, or lightning damage, or localized change in lubrication condition

Periodic Inspections

ASME 30-1.8.1 (c) states that:

“The inspection frequency shall be based on such factors as rope life on the particular installation or similar installations, severity of environment, percentage of capacity lifts, frequency rates of operation, and exposure to shock loads. Inspections need not be at equal calendar intervals and should be more frequent as the rope approaches the end of its useful life. Close visual inspection of the entire rope length shall be made to evaluate inspection and removal criteria.”

According to the ASME B30.30 Ropes Standard, inspectors will look over the entire wire rope length and focus on uncovering various forms of damage, as well as sections prone to rapid deterioration or needing “special attention,” including:

- Repetitive Wear Sections

- Flange step-up, crossover, and repetitive pickup points on the drum

- Reverse bends in the reeving system

- Equalizer sheaves

- End connections

- Sheave/drum groove wear or corrugation

- Known Wear Areas Based on Previous Experience with the Machine Being Inspected

- Locations Where Rope Vibrations are Damped

- Sections in contact with equalizer sheaves or other sheaves where rope travel is limited

- Sections of the rope at or near end connections where corroded or broken wires may protrude

- Rope in the bridle reeving in boom hoists

- Repetitive pickup points and crossover and change-of-layer points at flanges on drums

- Fleeting or deflector sheaves

Timing of Crane Rope Inspections

Not all ropes are judged on the same criteria, and based on their usage, the frequency of inspections differ.

The ASME B30.30 Ropes Standard states that “Unless otherwise specified by the LHE manufacturer, the rope manufacturer, or a qualified person, the periodic inspection shall be performed at intervals according to the rope service descriptions.”

To make sure you remain in compliance with ASME standards, follow these recommendations for inspections:

Boom Hoist Rope Inspections

- Normal Rope Service-Not to exceed three months or 500 hours of rope operation, whichever comes first

- Heavy Rope Service-Not to exceed two months or 335 hours of rope operation, whichever comes first

- Severe Rope Service-Not to exceed one month or 165 hours of rope operation, whichever comes first

- Special Rope Service-Less than 165 hours of rope operation

All Other Wire Rope Inspections

- Normal Rope Service-Not to exceed 12 months or 2,000 hours of rope operation, whichever comes first

- Heavy Rope Service-Not to exceed six months or 1,000 hours of rope operation, whichever comes first

- Severe Rope Service-Not to exceed three months or 500 hours of rope operation, whichever comes first

- Special Rope Service-Less than 500 hours of rope operation

Ropes that require special attention and reduced time intervals between periodic inspections include:

- Unique construction and susceptibility to damage and increased deterioration when used under difficult conditions

- Duty cycle operations

- Rope operating in chemically active environments

- Rope other than Category 1 rotation-resistant rope operating with active in-line swivels

- Rope operating over synthetic sheaves with single-layer drums

Ropes affected by “unusual occurrences” include:

- Lightning strike

- Abnormal shock load

- Overload on a wire rope

- Under the ASME B30.30 Ropes Standard, “The wire rope shall be inspected in accordance with or as determined by a qualified person.”

Common Types of Wire Rope Damage Found During Inspections

What problems are inspectors looking for during an examination of the wire rope?

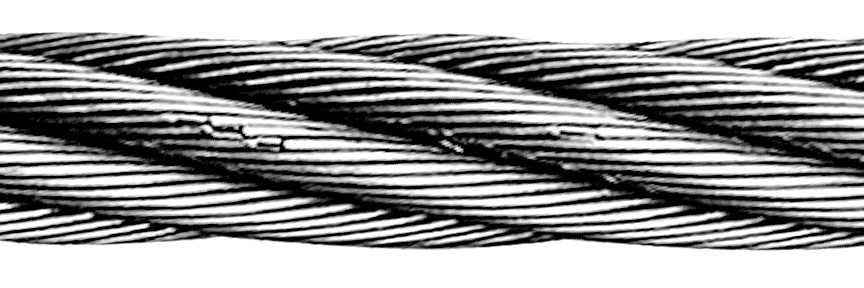

According to ASME B30.30, damage to wire rope comes in many forms, including:

- Rope Diameter-The rope should be measured in numerous locations to check for any loss of diameter. Removal criteria include a reduction from nominal diameter greater than 5% at any location.

- Distortion of Rope Structure-Examples of this form of damage include kinking, severe doglegs, bird caging and crushing. Removal criteria include steel core protrusion between the outer strands, kinking, severe doglegs and changes in original geometry due to crushing where the minimum dimension across the distorted second is less than or equal to 5/6 of the nominal diameter.

- Corrosion-Removal criteria include widespread or localized external corrosion as evidenced by pitting and obvious signs of internal corrosion, such as magnetic debris coming from valleys.

- Waviness of Rope-Removal criteria include when the overall envelope diameter has increased to a value greater than 110% of nominal rope diameter.

- Heat Damage-Removal criteria include any apparent damage from a heat source, such as welding, powerline strikes, or lightning.

- High or Low Strand-Removal criteria include a high or low strand that is higher or lower than half of the strand diameter above or below the surface of the rope.

- End Terminations-Removal criteria include severely corroded, cracked, deformed, worn, grossly damaged, or improperly installed end terminations.

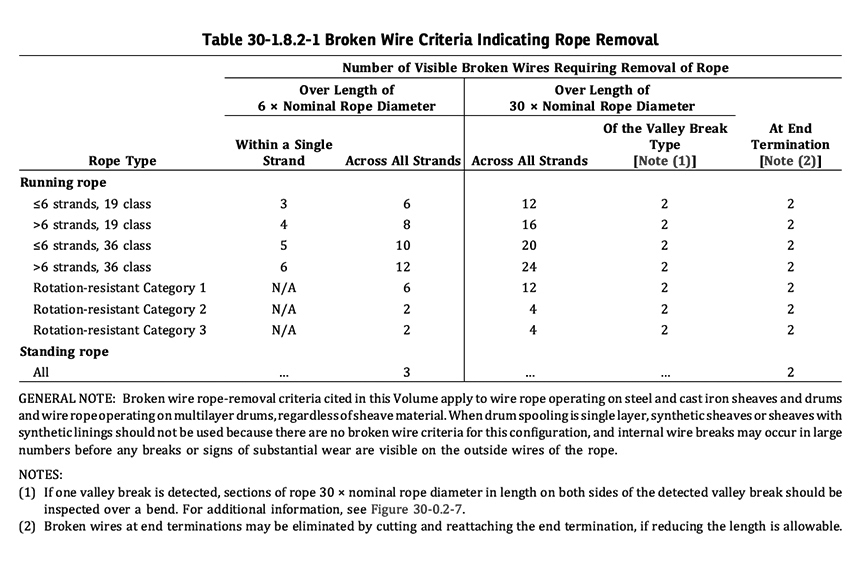

- Visible Broken Wires-See table below for variances given depending on rope usage.

Crane Rope Inspection Records

Types of inspections have different requirements for their records keeping, per ASME B30.30.

Records of frequent inspections are not required.

“To establish a basis for judging the proper time for replacement, a dated report of rope condition at the latest periodic inspection shall be kept on file….

…If the rope is replaced, only the fact that the rope was replaced needs to be recorded.”

Long-Term Inspection Programs “should be established and should include records on the examination of rope removed from service so that a relationship can be established between visual observation and actual condition of the internal structure.”

Wire Rope Lifespan and Disposal Criteria

Section 30-1.8.2 states, “There are no precise rules to determine the exact time for the removal of the rope since many factors are involved. Once a rope reaches any one of the removal criteria, it shall be replaced before the LHE is returned to service.”

Wrapping It Up

By better understanding the ASME B30.30 Ropes Standard for inspection, you have a deeper understanding of the importance of having your equipment examined regularly and have taken the first step in creating a safer work environment for your employees.

Also, you know now that inspecting equipment is not just a periodic requirement done by an outside company. If you notice something is suspect, you should pull it from service for further evaluation and potential retirement/disposal.

Safety and successful lifts are everybody’s responsibility.

Call us at 800.362.4601, or click here for more information on wire rope products or assemblies!