What Can You Expect from a Mazzella Crane Rope Installation?

Do you have questions about the process of installing high-performance ropes on a crane? Mazzella goes to great lengths to ensure the removal of old ropes and installation of new ones is as smooth as possible and limits the amount of downtime for a crane.

How long will it take to remove and replace the old rope when the technician, assistants, and supplies arrive on-site?

For some small cranes, the timeframe could be as little as 45 minutes, but for larger cranes, removing the old rope and installing the new one could be a several-hour process.

There are a lot of factors that go into a successful crane ropes installation. The most important thing is the quicker your supplier responds to your order and gets a rope on location, the quicker that rope gets installed properly, which saves you time and money.

Downtime is the key, and it could cost your company tens of thousands of dollars per day if your crane(s) are inoperable.

When Mazzella fulfills a crane ropes order, it is not just about the sale and the bottom line.

While we’re in the business of selling crane ropes, we’re also in the business of building relationships and trust. We’ll always work with and serve you, and are committed to making sure you get the correct products for the right applications.

That honesty and trust is of utmost importance for the safety of your workers and the proper maintenance of your cranes.

In this article, we will discuss the process of replacing the high-performance crane ropes on a Grove® RT9150 rough terrain crane, including:

- How to prepare the spooling truck to pull the old rope off the crane

- What is a Job Safety Analysis (JSA)?

- How the old cable is pulled off the crane

- Preparing a new crane rope to spool onto a crane

- Properly seasoning your crane rope

Properly Preparing for New Crane Ropes

Say you and your company avoid the pitfalls of ordering the wrong crane rope and have a new spool on its way. Once the order process is done, what can your company do to prepare for delivery and installation?

As much as Mazzella can be prepared on our end, you need to be ready for the installation so the process can go as smoothly and safely as possible.

You have to make sure the technicians have the space to perform their duties. The easier it is for the installers to get on-site, get to work and finish their responsibilities, the faster your company can get back up and running.

It is a good idea to:

- Give management the proper notice of when the installer will be on-site

- Have the necessary technicians on-site to help the installer with the rope replacement

- Make sure the installer / technicians have a clear working space

There’s a lot of downtime and waiting associated with being unprepared for an installation, so the more prepared you can be for the install, the better. You don’t want a situation where your crane is inactive because of an oversight or completely avoidable situation.

Also, Mazzella recommends you measure your sheaves with a sheave gauge. A sheave gauge will help you measure the wear of the root, the amount of wear on the groove wall, and the diameter of the wire rope.

How Far Should Your New Cable Be from the Crane?

To start, Mazzella installers want 60’ of space between the tip of the boom and the new cable.

If you’re not keeping the cable we’re pulling off, this isn’t necessarily a factor. However, before we install the new rope, we must be 60’ from the boom tip, or 120’ from the car body.

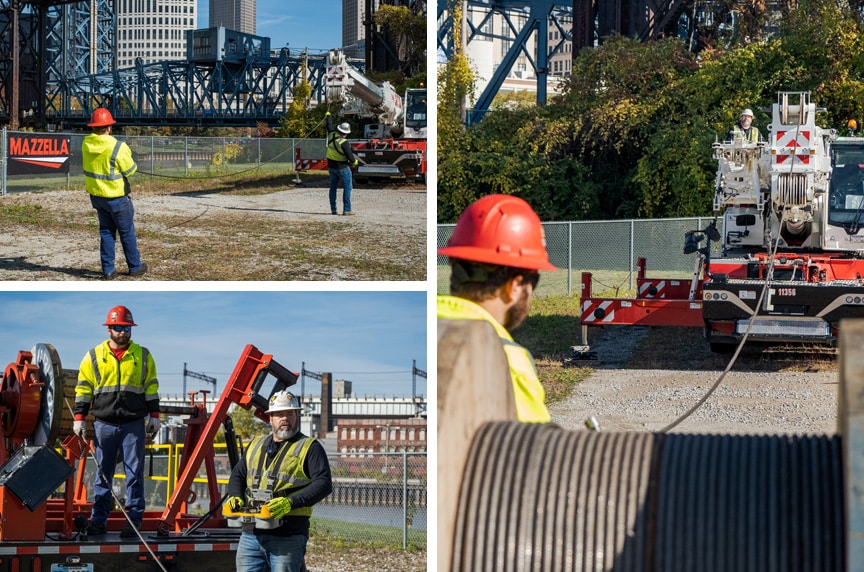

Setting Up the Spooling Unit

We start by putting down the walkways on the sides of our spooling truck to allow for easy access to the equipment.

Then, we disconnect the chain on the chain drive assembly, push down to release the tensioner, and disconnect the chain from the sprocket on the assembly.

When we’re installing the chain on the assembly, we start at the top and push the chain around. Then, we make sure the chain tensioner is on and engaged so the removal spool can be used to take off the used rope.

***Remember to ensure all equipment is powered off and locked out / tagged out, per OSHA 1910.147 Lockout / Tagout regulation, before doing any removal or installation of high-performance specialty wire ropes.

How Is the Old Rope Removed from the Crane?

At the top of the boom tip, there are two pins that must be removed before the removal and installation processes begin to avoid damaging them when we’re pulling off the rope. Doing so prevents any rubbing or cutting into the end of the pins.

Once the pins are removed, the installer begins to pull out the used rope, hand over hand, with the end of the whip anchored on the ground. By doing this, you’re pulling off twice the cable, or as our installers say, “Work smarter, not harder.”

We always keep tension on the cable when pulling it off the crane. This is done to prevent the rope from back spooling onto the drum. The initial pull of the crane ropes will be at least the 60’ of distance between the spooling truck and the boom tip.

Often, a staple is put into the reel to hold down the end of the rope before the spooling drum is used to pull off the remainder of the cable. Also, we’ll make sure there is a clear path from the boom tip to the spooling drum.

Then, the installer picks up a heavy-duty hammer to help guide the rope as it is spooling onto the drum. We don’t ever put our hands on a used cable, or any cable for that matter. The hammer is used to help control the spool.

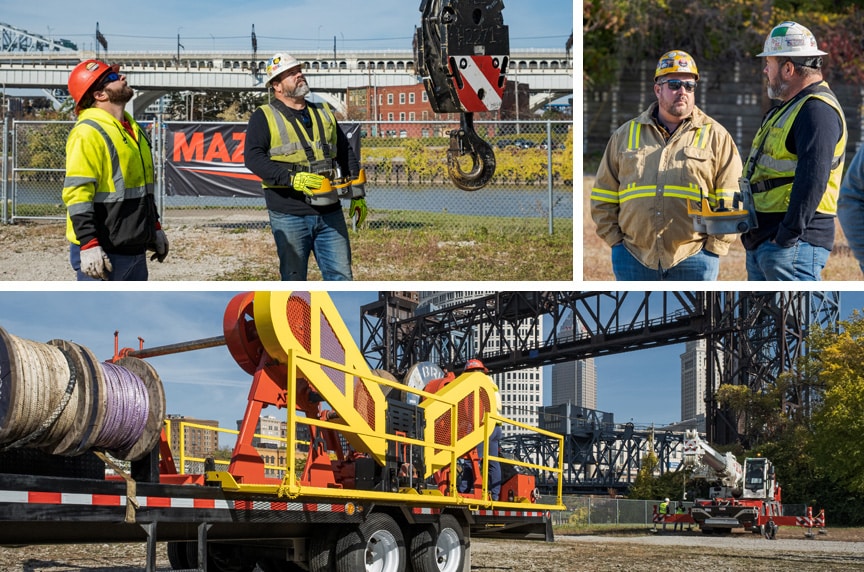

The last step of the preparation process is turning on and warming up the truck. While that is being done, our installer talks with the crane operator and reviews the Job Safety Analysis.

What Is a Job Safety Analysis (JSA)?

A Job Safety Analysis (JSA) focuses on the relationship between the worker, the task, the tools, and the work environment—and identifies hazards before they occur.

One of the first things that you can do to help keep your job site safe is to begin identifying hazards. OSHA defines a hazard as a condition, or a set of circumstances, that present a potential for harm. A hazard is often associated with a condition or activity that will cause illness (health hazard) or physical harm or injury (safety hazards).

Hazards are the main cause of occupational health and safety problems. The single most effective way to assess safety management on your job site or facility is to perform a Job Safety Analysis, or JSA.

After a hazard is identified, a determination is made on how to control or eliminate the hazard altogether.

Performing a job safety analysis is truly invaluable. By controlling or eliminating hazards in the workplace, you help reduce the risk of an accident. Think about how quickly the costs of a workplace accident or fatality can add up, including:

- Lost wages

- Workers’ compensation

- Low employee morale

- Decrease in productivity

- Workforce shortages

- Potential legal fees and OSHA fines

During the process, our installer will pull off the slack in the cable until they get tension and give the crane operator the signal to feed the rope. When the rope is down to a bed layer, the operator will slow down the crane, and the cable will be removed slowly until there are only one or two wraps remaining on the drum.

At that point, the installer will stop the spooling drum, but the crane operator will feed the remainder of the line to put slack in the rope. That will allow for the old cable to be removed from the drum.

If the operator stops feeding the line at any point, that will stop the spooling drum. The faster the operator feeds the line, the faster the spooling drum will pull off the old rope.

How Is the Old Rope Removed from a Crane?

After the old cable is connected to the spooling drum and the JSA has been completed / agreed upon, the installer will check to make sure the controls are in proper working order. Also, the installer will make any adjustments necessary to the tensioner and the accelerator.

Adjustments to the tensioner need to be made slowly to initiate the spooling process. Then, the installer will go to the back of the truck and use the heavy-duty hammer to help guide the rope as it is spooling onto the drum.

When the cable is tight, the installer will increase the pressure on the tensioner. The hammer is used to help the installer avoid being hurt from broken wires or anything else that can snag their gloves.

Getting a New Crane Rope Ready to Spool onto a Crane

As the crane operator pulls out the remaining cable, our installer will get the new crane ropes ready to install. This helps prevent downtime, as when the crane operator is ready for the new rope to be installed, they do not have to wait for it to be prepared.

Much like how the old rope is started, the new rope will be pulled off the spooling drum, hand over hand, until it reaches the boom tip.

How Is a New Rope Spooled onto a Crane?

Once the new rope is near the boom tip and the crane operator has removed the old cable, the new one will be put into the drum. When that is completed, the installer will tension up a T-bar on the side of the spooling drum until it is hand tight.

Installers don’t put too much tension on the crane ropes because when the crane operator starts pulling, the rope will suck down in on itself. One layer is okay, but two layers is not, and that is controlled by the tensioner.

Whenever Mazzella spools new ropes onto a crane, we’re not giving you the full tension. We’re giving you enough tension to spool onto your crane.

How Do You Break In the New Rope?

Following the install’s completion and the blocks are re-reeved, the installer will have the operator sign the ticket and will explain the process of seasoning the new crane rope.

Before making your first pick with the new rope, you need to scope out the boom to its full length, then, take the rope down to the ground to pick up an object between 5-10% of the working load limit of the cable. At that point, you’ll be in the lagging, and that is when you’ll get your actual working tension on the cable.

You need to pick up and bring back down that 5-10% load between four and five times to season the rope properly and make sure it sits on the drum correctly before putting the crane back into service.

How Can Mazzella Help You With Crane Ropes Installations?

We hope this article helped you understand more about Mazzella’s process for installing crane ropes, and why the process for ordering from us is so comprehensive.

Mazzella has one of the largest crane ropes inventories in the United States…ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM (original equipment manufacturer) assemblies:

- In sizes from ¼” to 3” diameter and 9mm to 52mm diameter

- Domestic and Non-Domestic

- In stock and ready for same or next-day shipment from one of our many service centers

Also, we can manufacture assemblies with standard or custom end fittings. Special testing and tolerance requirements are available.

Again, with our experience and access to all brands of wire rope, Mazzella guarantees we’ll get you the correct rope for your cranes. Email craneropegroup@mazzellacompanies.com with any questions or to schedule your next crane rope project. Call us at 800.362.4601 or click here to get the high-performance wire ropes you need!

Crane Ropes

One Brand of Rope Will Not Work on Every Machine!

Mazzella stocks a large inventory of high-performance wire ropes available for immediate delivery.

We stock our various high-performance ropes at our many locations in sizes from 1/4” to 3” diameter and 9 mm to 52 mm diameter.

We stock both domestic and non-domestic products ready for same or next day shipment from one of our many service centers.

Copyright 2022. Mazzella Companies.