Which Verton EVEREST SpinPod™ Unit Is Best for Me?

How do you decide which Verton EVEREST SpinPod™ unit is best for your overhead lifts? Here is a breakdown of the differences between the Verton EVEREST SpinPod™ units, and some other alternatives, too.

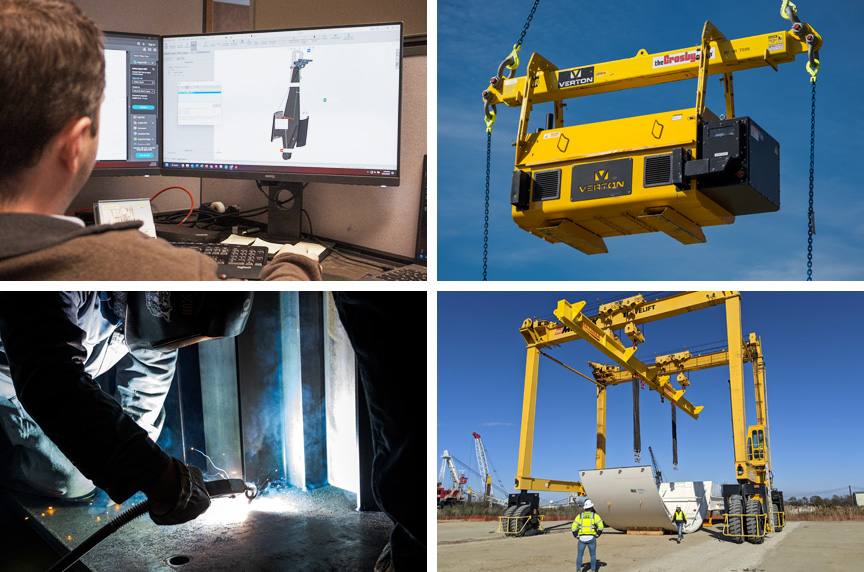

Verton, which The Crosby Group is a partner and master distributor of, has focused on making load control easier and safer through technology.

With their fully-defined mission, Verton created the EVEREST series, which is a collection of load-oriented solutions that eliminate the need for taglines and pulls workers away from overhead lifts. The primary goals are safety and being safety-minded, keeping your workers away from a load, away from pinch points, and managing risks with taglines.

The hands-free lifting solution handles suspended loads through a remote control. That removes the need to have workers in the drop zone and being in contact with the load. Also, the Verton EVEREST SpinPod™ will meet your lifting operation standards by eliminating taglines.

Using the Verton EVEREST SpinPod™ can lead to significant reductions in:

- Downtime

- Hook time

- Overtime

- Time spent and fewer riggers required to orient and control suspended loads

In this article, you’ll learn the following:

- What the Verton EVEREST SpinPod™ is

- How the models differ from each other

- Unique features and benefits of the Verton EVEREST SpinPod™

- Which Verton EVEREST SpinPod™ model is right for you

- What alternatives are available

What Is the Verton EVEREST SpinPod™?

The Verton EVEREST SpinPod™ 7.5 and 30 are load-orientation solutions that allow you to have 360° control of the load under a spreader bar.

The Verton Everest SpinPod™ is a piece of equipment that attaches to a spreader bar and applies torque to move the suspended load on its axis. The unit runs on battery power and uses gyroscopic principles to transfer energy generated from the spinning flywheels into torque to orient the suspended load.

With the SpinPod, riggers can control a suspended load from a safe distance (up to 200 m), making lifting operations hands-free.

This technology has been developed with the intention of removing operators from the danger zone. With the ability to control lifts remotely, riggers are no longer required to be near suspended loads to push or pull a tagline. Removing riggers from the vicinity of suspended loads is a significant improvement in safety in these very challenging and dangerous operations.

Instead of using taglines, the Verton EVEREST SpinPod™ allows you to:

- Reduce and reallocate resources with only a single operator needed to rotate loads

- Gain better oversight with dashboard integration analyzing live metrics from onboard sensors and through smart technologies

- Plan, track, analyze, and benchmark projects to improve efficiency

Breaking Down the Verton EVEREST SpinPod™ Models

EVEREST SpinPod™ 7.5

This version of Verton’s gyroscopic technology provides a modular solution for precise remote load orientation and control. It eliminates taglines for a “hands-free” lifting operation.

The Verton EVEREST SpinPod™ 7.5 attaches to your existing spreader beam or a Verton-certified spreader bar. Customized configurations will help you with unique rigging situations.

Features of the Verton EVEREST SpinPod™ 7.5 include:

- A 5-30 ton rotational capacity (based on a single unit, higher with modular configurations)

- Remote-control load-management system

- Dashboard integration available

- Left, right, and hold functionality

- Low, medium, and high-rotation speeds

- 200 m line-of-sight remote control range with pitch-and-catch functionality

- Battery swap (optional)

- Works for onshore and offshore applications

EVEREST SpinPod™ 30

For larger and bulkier loads, Verton has scaled up to meet your precision load orientation needs with the EVEREST SpinPod™ 30.

Ready for orders, the latest evolution of the SpinPod™ provides more torque and still features all the same impressive functionality for precise load control and orientation as the Verton EVEREST SpinPod™ 7.5.

Operated by remote control, the rigger can now orient the load from a safe distance.

Features of the Verton EVEREST SpinPod™ 30 include:

- 20-100 ton rotational capacity (based on a single unit, higher with modular configurations)

- Remote-control load-management system

- Left, right, and hold functionality

- Low, medium, and high-rotation speeds

- 200 m line-of-sight remote control range with pitch-and-catch functionality

- IoT dashboard included

- Battery swap (optional)

- Works for onshore and offshore applications

What Factors Determine Which Model Is For Me?

Before ordering an EVEREST SpinPod™ device, safety managers and construction forepersons must understand the type of work their employees will be conducting and the environment in which the equipment will be used.

It is important to know the answers to the following questions before deciding on which Verton EVEREST SpinPod™ model is right for you:

- What is the weight of your lifts?

- What environments will the Verton EVEREST SpinPod™ be used in?

- What is the size of the space where the Verton EVEREST SpinPod™ will be used?

Using a Verton EVEREST SpinPod™ allows the planners to tackle challenging lifts in a different and smarter way.

What Are the Unique Features and Benefits to Using the Verton EVEREST SpinPod™?

Increased Load Control

The SpinPod™ offers riggers and crane operators increased control and safety in their day-to-day operations. By using the SpinPod™, riggers can safely orient suspended loads with increased precision and efficiency.

Peace of Mind

For owners and operators, it provides peace of mind, knowing that as a business owner, you are providing your teams with the latest technologies and mechanical aids to help them do their jobs in a safer and more efficient way.

For lifting planners, it offers additional capabilities and opens the door to approach challenging lifts in a different way. By using the remote-control capabilities, planners can afford not to close some streets when working in the city. Also, the SpinPod™ addresses the skills shortages being experienced in many industries. With the Verton unit, jobs that would require a crew of five or six riggers, can now be completed with two or three.

Increased Efficiency and Productivity

With the increased precision of load orientation, some existing customers experience increased efficiency and are completing jobs ahead of schedule. Examples of efficiency gains from Verton end-users are 38, 62 and 400% improvements using the SpinPod™ over traditional methods with taglines. These efficiency improvements were achieved while improving safety at the same time.

When you start to get close to the desired spot for the lift, you can slowly tap the directional buttons to give the load its precise location.

Battery Life

The battery’s lifespan lasts between 8 and 10 hours of operational use. That’s live, active spinning of the unit itself. Also, the Verton EVEREST SpinPod™ has battery regeneration capabilities. When you get to the end of a pick and want to recapture some of that energy, you have the ability to slow down the flywheel and regenerate the battery on-site. The Verton EVEREST SpinPod™ has a standard 120-volt plug that can be connected to a generator or other sources of power.

The Verton EVEREST SpinPod™ batteries are IP67 rated. These batteries are completely protected from dust contact and protected against water submersion up to 1 m.

For the Verton EVEREST SpinPod™ to reach full power, it takes only about 45 seconds.

Multiple Configurations

One of the added benefits of using the Verton EVEREST SpinPod™ is you can add up to four units onto the spreader beam. Whatever spreader beam you use, you can design it to hold the required units to control the lift.

Exact Orientation Control

The remote control itself has six buttons, including:

- Left

- Right

- Speed (rotational speed of the flywheel in revolutions per minute)

- Reset (to bring the flywheel angles back to 0)

- Enable

- Hold

The Verton EVEREST SpinPod™ can engage automated rotational control to maintain its orientation, counteracting the load from rotating due to external forces.

With 200 m (about 650’) of line-of-sight control, the Verton EVEREST SpinPod™ is activated through pressing the “Hold” button. It will hold its orientation, relative to a specific orientation. This feature is particularly useful when lifting operations take place in windy conditions. By using the “hold” function, operators can line the load with the wind and press “hold.” Then, the SpinPod™ will ensure the heading remains the same until the unit is off “Hold” mode. Using this feature minimizes the effects of the wind.

At this point, the operator can change the hold orientation in increments / decrements of 1° by pressing the left and right buttons. This makes orientational control of the Verton EVEREST SpinPod™ very accurate for lifting operations where precision is of utmost importance.

Example: If you’re lifting a panel over a structure, you can get two remotes with this system with a pitch-and-catch feature. If you’re communicating with your rigger up top and guide on the ground and lose line of sight, you can cast it to that other remote, and they can control it from there.

Lifting Offset Loads

You need to understand to account for the height, weight and width of your load to lift is successfully. Something could weigh 10,000 lbs., be 50’ long, and it would have a different center of gravity than a 20-ton piece that’s just 5’ wide and 30’ tall. They will act differently in the air.

The most important thing with an off-center load is identifying the center of gravity. You want to be as close to that center of gravity as possible underneath the hook, which will give you the most reaction forces on the lift.

It comes down to incorporating this unit into your pick plans, too. In your pick plans, you want to identify:

- Who’s in charge of the remote?

- Who’s communicating with the crane operator?

Quick Change Battery Packs

These units come with a feature for a quick swap on the battery pack.

The battery is located on the left-hand side of the unit. You’ll get 8 to 10 hours of steady operation at 1,500 rpms. However, if you’re running the Verton EVEREST SpinPod™ all day, maybe even multiple shifts, and you need a secondary battery pack, you can:

- Pull a second battery pack off the charger

- Swap out the old battery with the new battery

- Continue your operation

- Battery changeover takes approximately 15 minutes

What Alternatives Does Verton Have If the EVEREST SpinPod™ Isn’t Right For Your Lifting Applications?

After doing your research and comparing the Verton EVEREST SpinPod™ models, you may find these units are not exactly what you need. However, that does not mean Verton cannot help you with your overhead lifts.

Verton offers alternatives for safer overhead lifts, including:

- The Windmaster

- Pipe Handling Solution

The Windmaster

Designed to make your wind turbine erection and maintenance safer, faster, and smarter, The Windmaster solution is Verton’s latest innovation in unlocking improvements in safety and productivity.

This adaptation of Verton’s technology will hit the market in late 2023 or early 2024. It was created specifically for lifting and orienting wind turbine tower sections, nacelles, and turbine blades without the need for taglines.

Features of The Windmaster include:

- Remote-control load-management system for wind turbine installation

- Eliminate taglines for “hands-free” lifting

- Install tower sections, nacelle and blades

- Increase your wind-operating window

- Integration with existing or specialty lifting yokes and rigging

- Onboard IoT, sensors and smart technologies

- Remote control with pitch-and-catch functionality

- Dashboard integration available

- Works for onshore and offshore applications

Pipe Handling Solution

Verton’s Pipe Handling Solution combines the remote load control of Verton’s Everest Series with Global Gravity’s TubeLock®, tubular transport and running system. This all-in-one system is designed to improve operational safety and productivity for onshore and offshore applications.

Really, the pipe handling solution was created to show that Verton can incorporate its solution within existing lifting devices.

How Can Mazzella Help With Your Below-The-Hook Lifting Devices?

Mazzella has partnered with The Crosby Group to become the first North American distributor of the Verton EVEREST SpinPod™. We will start the process by learning about your business. Then, we’ll determine if the EVEREST SpinPod™ is the right fit for your lifting application, and which unit is best for you.

Also, with close to 70 years of experience in designing, developing, and distributing custom engineered products, below-the-hook lifting devices, and lifting attachments, Mazzella can help you get the correct devices for your specific needs.

Know that by working with Mazzella to solve your problems, you will receive below-the-hook lifting solutions done in compliance with ASME B30.20 Below-the-Hook Lifting Devices and ASME BTH-1 Design of Below-the-Hook Lifting Devices standards.

If you don’t need new lifting solutions, we provide repair or recertification of engineered below-the-hook lifting devices to minimize your downtime.

Click here if you need a repair or recertification of your lifting device.

Call us at 800.362.4601 or click here to specify your next below-the-hook project!

Below-the-Hook Lifting Devices

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

Copyright 2023. Mazzella Companies.