Flemish vs. Turnback vs. Hand-Tucked Eye: Which One is Right for You?

When purchasing a wire rope lifting sling, how do you choose between a Flemish, Turnback, and a Hand-tucked eye? This article covers the pros and cons of each eye sling type and how to choose the right one for your organization.

Thanks to their immense durability, wire rope slings have become commonplace in any construction, industrial, mining, or manufacturing environment involving overhead lifting.

While wire rope slings appear to be a monolith on the surface, they’re an incredibly diverse tool—ranging in size, type, configurations, and functionality. One of the best examples of this diversity is the three eye sling types: Flemish, Turnback, and Hand-tucked.

Knowing the differences between these eye configurations is important, as each one has its best use cases and weaknesses.

From mom-and-pop construction companies to America’s largest steel mills, Mazzella has provided top-of-the-line wire rope slings to organizations for several decades.

We know it can be confusing to decide what wire rope eye sling type is best for your organization’s needs.

To help you in your decision-making process, this article will answer questions like:

- What is a Flemish, Turnback, and Hand-tucked eye?

- What are the pros and cons of each eye?

- What are the inspection requirements for each eye sling type?

- Which wire rope eye sling is right for you?

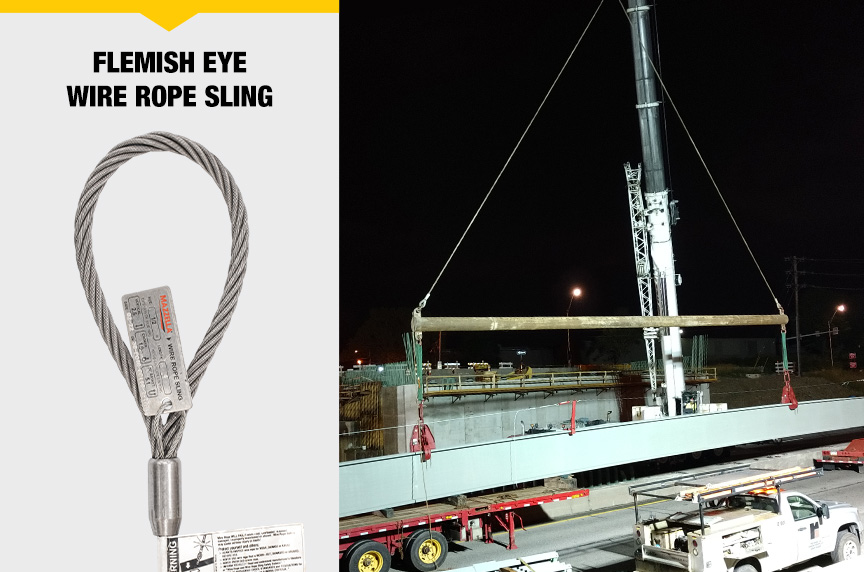

What Is a Flemish Eye?

According to our lifting and rigging experts, the most common type of wire rope eye sling in the United States is the Mechanical Splice Flemish eye.

The Flemish eye is made by opening the wire rope’s individual strands into two parts. From there, the two strands are looped in opposite directions and laid back together—creating an eye shape at the end of the wire rope. Mechanical Spliced Flemish Eyes are traditionally preformed with a general purpose 6×19 or 6×37 Independent Wire Rope Core (IWRC).

Once the eye shape is formed, the rope is fitted with a carbon-steel (sometimes aluminum or stainless steel) sleeve. The rope is then fed into a hydraulic machine, called a swager, that helps form and fit the sleeve in place.

What are the Pros of Using a Flemish Eye?

Thanks to its splicing method, the Flemish eye is the most efficient and economical wire rope eye type available.

Additionally, if there were any malfunction or failure with the carbon-steel sleeve, the Flemish eye could potentially be able to reach its working load limit.

While this isn’t ideal—and properly inspecting your lifting slings can prevent this situation—you could still avoid dropping the load. It would also give you enough time to replace the damaged wire rope sling. If a Flemish eye sling is unswaged and not discovered in time, our lifting and rigging experts say you should set the load down immediately.

What are the Cons of Using a Flemish Eye?

Depending on the job application, the sleeve could interfere with the sling coming out from underneath a load.

For example, iron workers usually prefer using a hand-tucked style sling, since they don’t have a sleeve that could interfere with placing a load in a choker hitch.

What Is a Turnback Eye?

Also referred to as a “fold back loop,” “returned-loop,” or “double-deck eye,” the turnback spliced eye is made by bending the rope against the live portion to the free end by using a steel or stainless steel (drop protective) sleeve.

Like the Flemish eye, this sleeve is crimped with a hydraulic swedger. According to our lifting and rigging experts, Turnback eyes are a popular option in European- and Asian-based industries.

What are the Pros of Using a Turnback Eye?

The Turnback eye is arguably the easiest and fastest sling eye configuration. Since you’re folding one side of the rope to the other, you don’t have to divide the wire rope’s individual strands into two parts. Turnback eyes also have high-efficiency ratings, and they can achieve a 5:1 design factor. While it’s quick to fabricate, strict tolerances need to be met with the sleeve’s finish.

What are the Cons of Using a Turnback Eye?

While turnback eyes have excellent efficiency ratings, the lifting capacity of the sling is entirely dependent on the sleeve’s integrity. If the sleeve fails, the entire load will be dropped, putting your workers at an increased risk of injury or death.

Due to strict requirements around the fabrication process, Turnback eyes are not common on most US job sites when compared to other countries.

What Is a Hand-Tucked Eye?

Used in select industries, the Hand-tucked eye is formed when the shorter “dead” end is hand-tucked or taper and concealed into the longer “live” end of the wire rope.

What are the Pros of Using a Hand-Tucked Eye?

Thanks to its design—which doesn’t include a sleeve—hand-tucked eyes allow for an easier inspection of the wire rope and strands. In some applications, not having that sleeve also makes placing a load in a basket hitch easier. This function is why iron workers prefer them over Turnback and Flemish eyes.

If inspected and tested properly, hand-tucked eyes are a great option in the right applications.

What are the Cons of Using a Hand-Tucked Eye?

While they make for easy inspections, Hand-tucked slings lack the versatility offered by other wire rope slings. If a Hand-tucked sling is used in a vertical configuration and does not have a proper tag line, the sling is susceptible to coming undone.

Additionally, Hand-tucked eye slings will have less lifting capacity than a standard mechanical-spliced sling.

What are the Inspection Requirements for Flemish Eye, Turnback, and Hand-Tucked Slings?

Whether it’s a Flemish, Turnback, or Hand-tucked eye, you will follow the same inspection and safety requirements laid out in ASME’s B30.9 Slings standards.

First, make sure you have the right sling for the job. This means answering important questions, like: will it be exposed to extreme temperatures? How often will you use it? What’s the lifting capacity?

From there, make sure a proper sling tag is attached to every wire rope sling at your job site. This tag will help riggers determine the best application for the sling.

After that, conduct a visual inspection of your sling. While inspecting, look out for deformations, kinks, loss of diameter, severe bends, dog legs, and any broken wires around the sleeve or at the base of the sling (follow the 5-10 rule for standard slings).

If any of these abnormalities are found, remove that sling from the job site.

Which Wire Rope Sling Configuration is Right for You?

Wire rope slings have proven to be an exceptional lifting device, and there’s a good chance you are already using them at your job site. But we understand that wire rope slings are not a one-size-fits-all solution.

Understanding the differences between the three eye sling types will help your organization make the right choice, increasing your productivity and enhancing worker safety.

Mazzella has over 70 years of experience manufacturing and distributing lifting slings to industries nationwide. If you want to learn more about what lifting sling is best for your application, download our Lifting Sling Types & Term Guide for a comprehensive overview.

Copyright 2024. Mazzella Companies.