How Much Does a Lifeline Inspection Cost?

Whether you’re comparing quotes or trying to budget, this page gives you the clarity most providers avoid.

You’ll see what affects inspection pricing, what’s actually included, and how to get the best value, without cutting corners or facing surprise charges. You’ll also know what to expect before anyone sets foot in your facility, with guides, tools, and FAQs to help you make the smartest decision for your team and company.

Lifeline Inspection Pricing

| Service Type | Who Performs It | Used For | Typical Price Range |

|---|---|---|---|

| Standard Lifeline Inspection | Qualified Mazzella Inspector | Pre-engineered systems with documentation or Mazzella-installed systems | $500 – $2,000 |

| P.E. Lifeline Certification Inspection | Licensed Professional Engineer (P.E.) | Custom-built or undocumented systems requiring structural verification (P.E. may be required) | $2,500 – $10,000 |

All inspections are quoted on a port-to-port basis — this includes travel time from the nearest Mazzella location, on-site inspection time, and return. Bundling inspection services can help reduce costs.

What’s Included In Your Detailed Inspection?

Our inspections follow the intent of OSHA 1910/1926, ANSI Z359, and OEM specifications for fall protection systems. Each inspection helps validate the structural integrity, compliance, and safe usage of your fall protection systems.

- Each inspection includes (as applicable):

- Visual review of lifelines, anchors, and fall protection systems

- Inspection of harnesses, retractables, and lanyards (when included)

- Tagging and documentation of each system

- Evaluation of drawings, specs, and manufacturer criteria

- Structural verification (if required) by a Professional Engineer (P.E.)

- You receive a detailed report with:

- Inspection results, deficiencies, and recommendations

- Tagging status and required actions

- Notes on out-of-service systems and next steps

We inspect all system types—pre-engineered, custom, or undocumented—and flag any that require PE review.

Factors That Affect Inspection Cost

Contact Our Inspections Team

Frequently Asked Questions

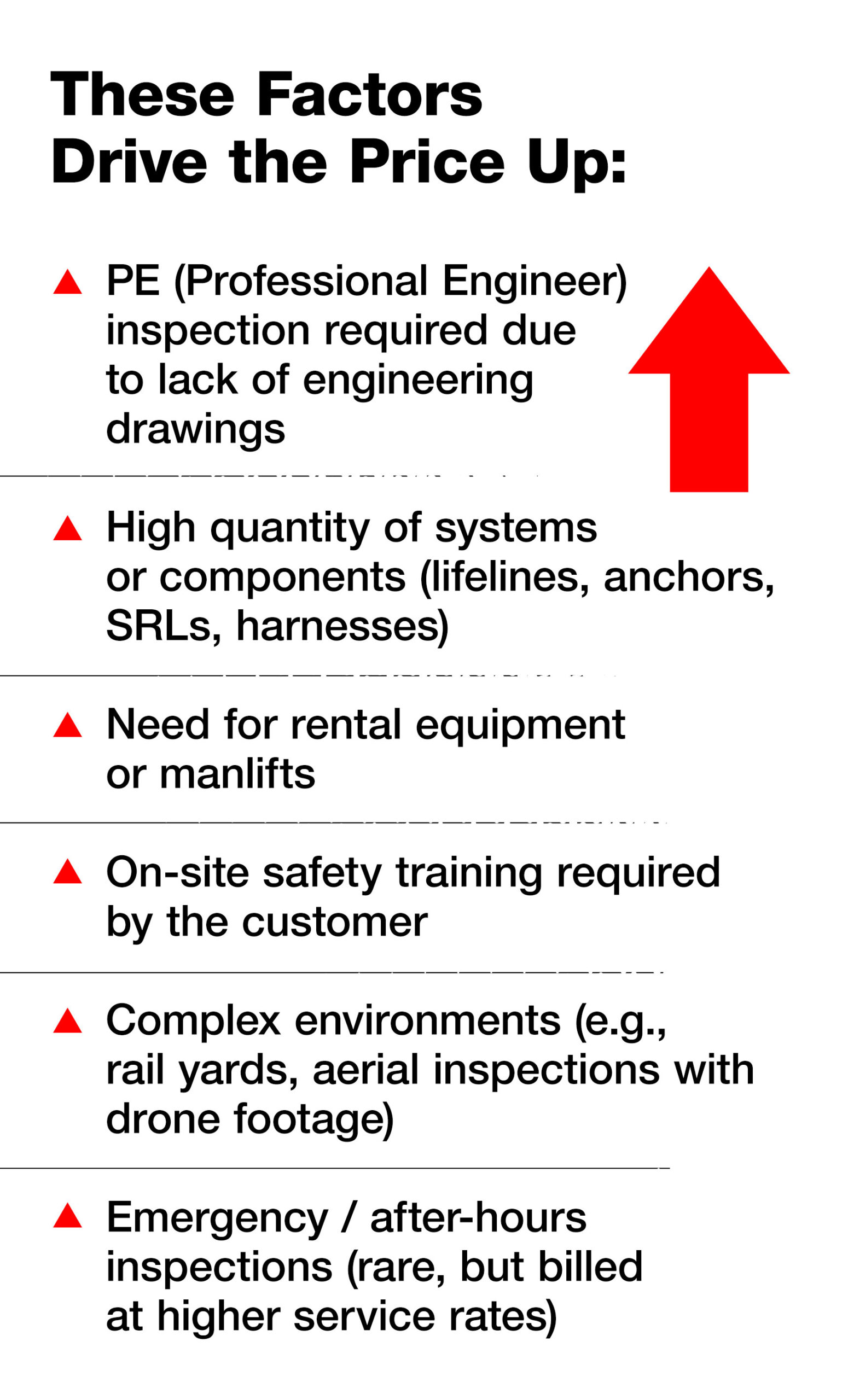

What factors drive the price up?

Several factors can increase the total cost of a lifeline inspection:

- PE (Professional Engineer) inspection required due to lack of engineering drawings.

- High quantity of systems or components (lifelines, anchors, SRLs, harnesses).

- Need for rental equipment or manlifts.

- On-site safety training required by the customer.

- Complex environments (e.g., rail yards, aerial inspections with drone footage).

- Emergency / after-hours inspections (rare, but billed at higher service rates).

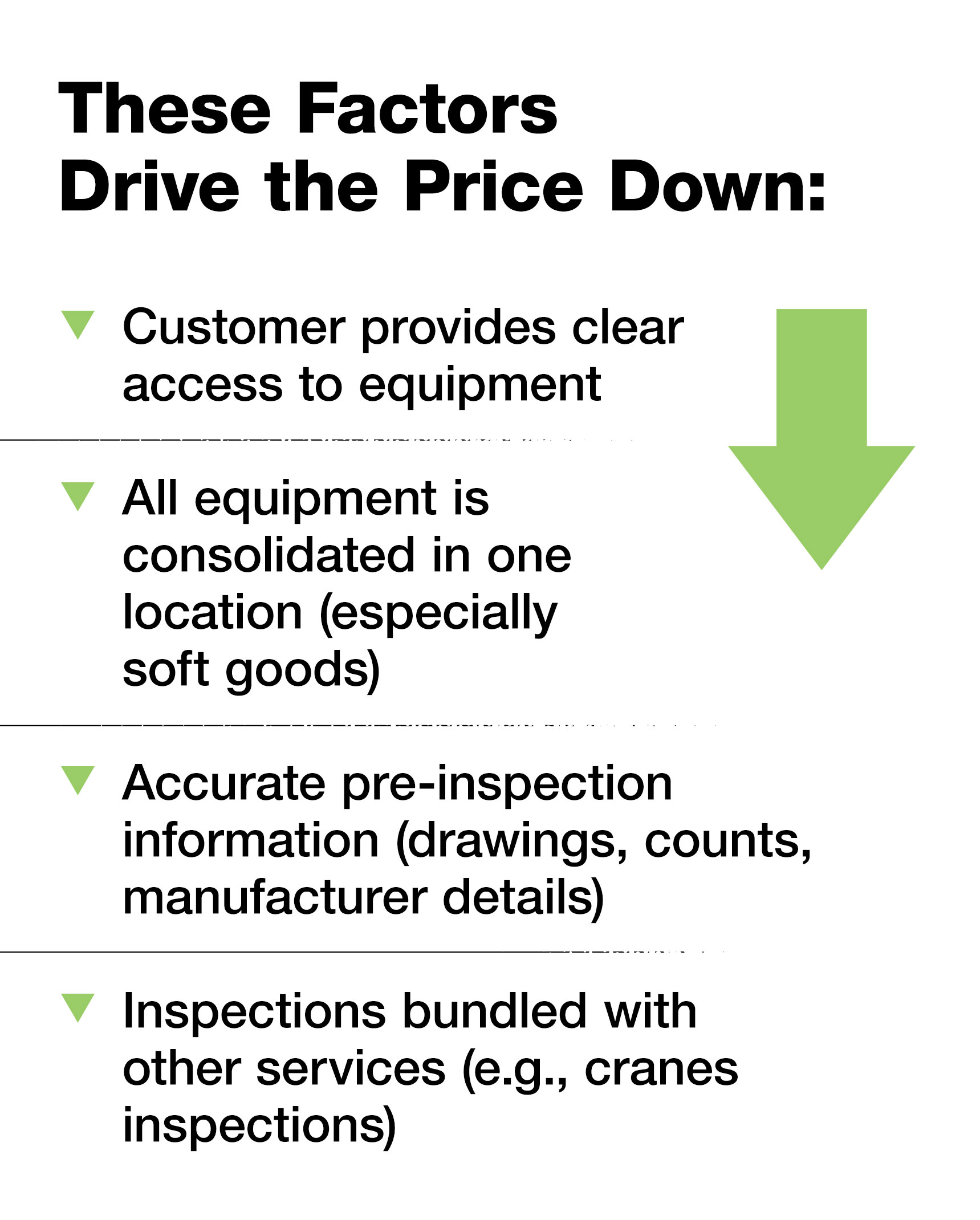

What factors drive the price down?

Fall protection lifeline inspection costs can be reduced if:

- Customer provides clear access to equipment.

- All equipment is consolidated in one location (especially soft goods).

- Accurate pre-inspection information (drawings, counts, manufacturer details).

- Inspections bundled with other services (e.g., crane inspections).

What makes some companies so expensive?

Higher-priced inspection providers often offer:

- PE-led inspections with full engineering analysis.

- Companies performing deeper structural integrity checks.

- Full reporting, documentation, and customer communication included in price.

- Focus on compliance, safety, and liability prevention — not just checking a box.

What makes some companies so cheap?

- Service inspections may be less expensive when a company has local technicians, which reduces travel-related costs.

- Some companies do not have access to Licensed Professional Engineers (P.E.) PE inspections may be more expensive due to involvement of a Professional Engineer and the need to evaluate structural support.

- Some companies perform only basic visual inspections, which lowers cost but limits scope. Others conduct more comprehensive evaluations, including a review of engineering drawings and verification of structural load capacity, which increases cost.

- Pricing can vary by region, inspection scope, and whether the provider includes documentation, tagging, or reporting.

Caution: “Free” inspections can be costly if they miss compliance gaps or expose you to liability.

Why does packaging vary in the industry?

At Mazzella, fall protection and lifeline inspections may be performed by a service technician or a Professional Engineer (P.E.), depending on the scope and requirements. A standard inspection includes a visual review of anchors, lifelines, and soft goods, as well as tagging, documentation, and a written report. When required, a P.E. can assess structural attachment points and verify that systems meet applicable load and compliance standards.

- Some inspections are performed by a service technician; others require a Professional Engineer (P.E.).

- A P.E. may be required when:

- Engineering drawings are missing.

- Custom or manually installed systems are in place.

- Structural verification is needed.

- Soft goods (lanyards, SRLs, harnesses) may be included if part of a larger system inspection; standalone soft goods may be handled by a separate process or team.

- Services offered and pricing structures vary across providers.

What’s the difference between a standard lifeline inspection and a P.E. lifeline certification inspection?

Depending on your system, you may qualify for a standard inspection — or you may be required to use a Professional Engineer (P.E.) to certify your lifeline.

Inspection Type Comparison

| Standard Lifeline Inspection | P.E. Lifeline Certification Inspection | |

|---|---|---|

| Performed By | Qualified Mazzella Inspector | Licensed Professional Engineer |

| Applies To | Pre-engineered systems with manufacturer documentation | Site-specific or custom systems with no supporting documentation |

| Eligible Systems | Systems installed by Mazzella, or built with known components | Systems lacking drawings, specs, or clearly defined inspection criteria |

| Cost | Lower cost | Significantly higher due to engineering involvement |

When is a P.E. inspection required?

A P.E. Lifeline Certification is required when:

- Your system is custom-built or field-fabricated.

- There are no drawings, specifications, or inspection guidelines from the manufacturer.

- The system requires engineering validation of structural integrity.

If your system does not meet these criteria, a standard inspection may be available — and more cost-effective.

Please note that all homemade systems will fail a visual inspection and will require a PE to validate the structural integrity.

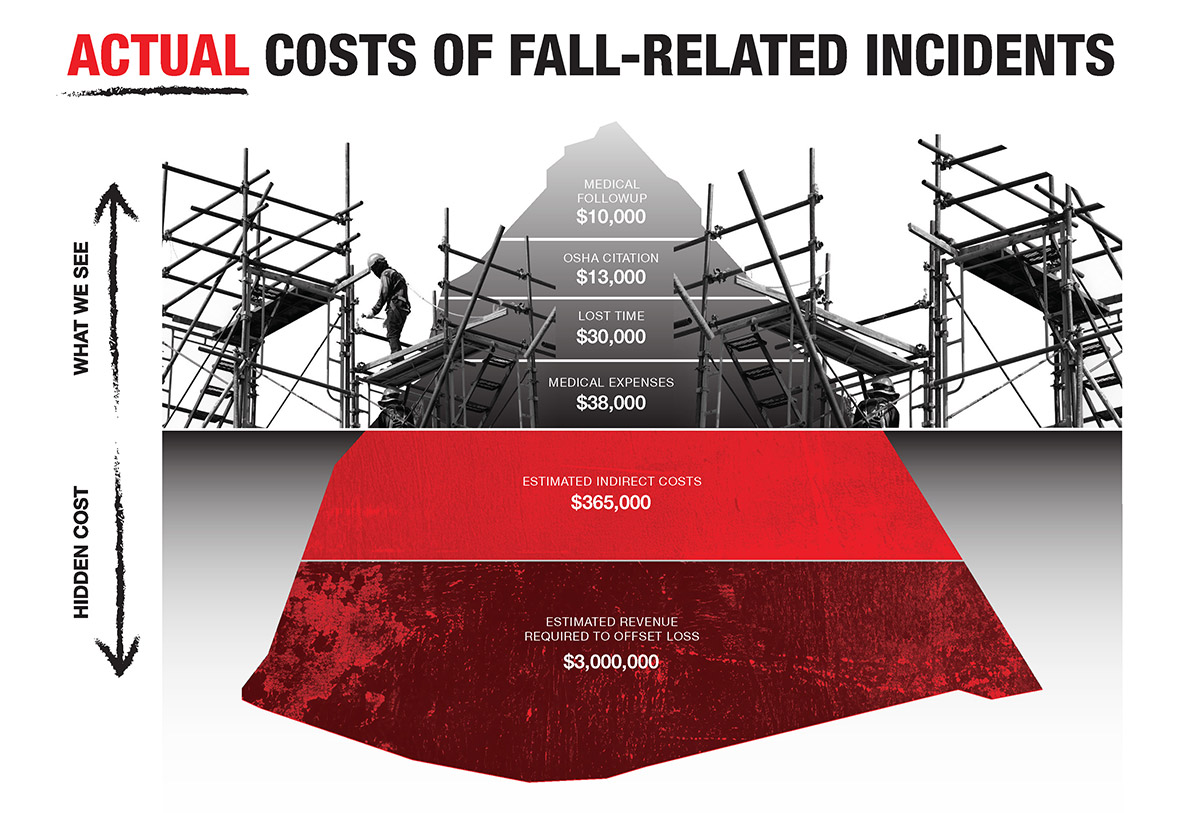

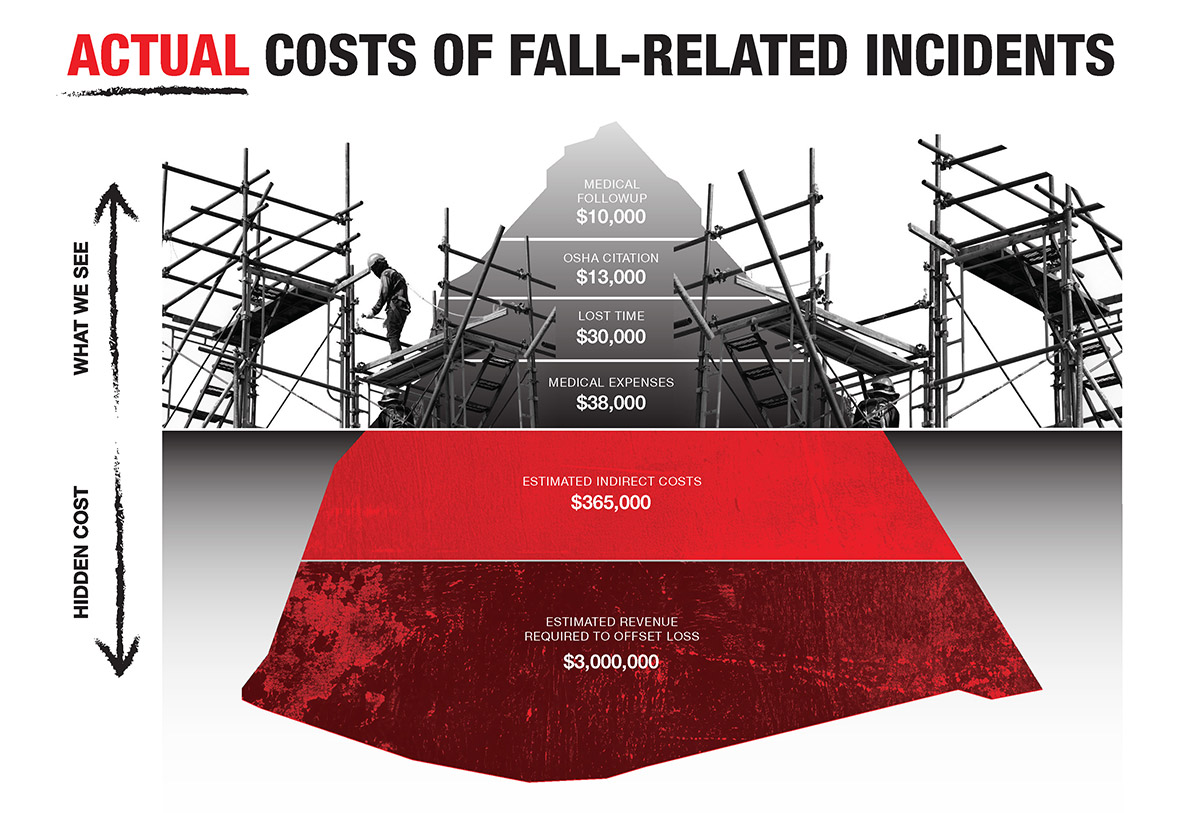

Lifetime Cost vs. Initial Price

Fall protection and lifeline inspections are required annually by OSHA. While inspections involve an upfront cost, the cost of a fall-related incident can be catastrophic by comparison.

According to data from the Department of Labor, OSHA, and CDC (2017–2018):

- OSHA citation (2025): $16,550 (serious) or $165,514 (willful / repeat)

- Average medical cost (2023): $43,000

- Lost time injury cost (2022): $51,047

- Medical follow-up and recovery: Over $10,000

- Estimated indirect costs: Over $365,000

- Estimated revenue required to offset loss: Over $3,000,000

These figures reflect averages — actual costs in fall-related incidents can be significantly higher, especially when legal exposure and brand impact are considered.

Have lifeline inspection rates changed recently?

- Pricing generally remains stable year over year, unless affected by internal labor rate adjustments or scope changes.

- Customers with multi-year service relationships typically see predictable pricing.

How does billing work for lifeline inspections?

- Pricing is typically invoiced after the inspection and report delivery.

- Payment terms depend on existing customer agreements.

- For enterprise accounts, Master Service Agreements (MSAs) may establish predefined pricing structures.

- Bundling lifeline inspections with other services — like overhead crane inspections — can reduce total service costs and simplify scheduling and billing.

What’s included in the lifeline inspection cost?

Your inspection cost includes more than just a quick visual once-over — it covers a full evaluation of your fall protection systems by a qualified Mazzella inspector or, if required, a licensed Professional Engineer (P.E.).

Depending on the scope of the inspection, here’s what may be included:

- System Components Inspected (as applicable).

- Permanent horizontal lifelines

- Temporary horizontal lifelines

- Vertical lifelines

- Fixed D-ring anchors

- Standing seam roof anchors

- I-beam trolleys, jib systems, rail systems

- Confined space tripods

- Mobile fall protection systems

- Soft goods (harnesses, retractables, lanyards)

- Structural Inspection Services Include:

- Inspection criteria aligned with:

- ⮕ OSHA 1910 & 1926 (fall protection compliance)

- ⮕ ANSI Z359 (fall protection equipment standards)

- ⮕ OEM specifications for your installed systems

- Tagging and documentation of all systems

- Inspection reports detailing findings, deficiencies, and recommendations

- Verification against manufacturer specs or engineering drawings

- Structural review (if required) by a P.E.

- Coordination for access equipment (aerial lift, etc.)

- Optional bundling with other services (e.g., crane inspections)

- Inspection criteria aligned with:

Your team will also receive guidance on what passed, what failed, and why — including whether issues can be corrected, or if the system must be taken out of service. Where drawings or documentation are missing, we help determine whether a standard inspection or a full P.E. certification is required.

Are there any hidden costs?

There shouldn’t be — but in this industry, not every provider is transparent.

With Mazzella, you’ll always know what’s included up front. However, there are a few common add-ons across the industry that can increase cost:

- Professional Engineer (P.E.) certification, if required.

- Rental equipment (like lifts) if not available on-site.

- After-hours or emergency scheduling.

- Follow-up services like repairs, re-inspections, or training.

We’ll always flag these during the quoting process to avoid surprises.

Why should I budget for qualified third-party lifeline inspections?

Because the cost of doing it wrong can be catastrophic.

A qualified third-party inspection:

- Keeps you OSHA-compliant — inspections are required annually.

- Identifies risks before they cause downtime, injuries, or fines.

- Provides neutral, expert documentation you can trust in audits or litigation.

- Validates structural integrity — especially if drawings are missing or systems are custom-installed.

- Protects your people and your business — financially, legally, and morally.

Whether you’re a facility manager, safety lead, or EHS director, budgeting for a third-party inspection isn’t just smart — it’s mandatory in most cases.

How to Prepare for Your Inspection

Preparing properly can reduce inspection time, avoid delays, and lower your total cost. Here’s how to get ready:

✅ Before the Inspection:

- Know where your lifelines are located ⮕ Identify the location of each system within your facility or site — time spent tracking them down increases cost.

- Provide accurate system information ⮕ Include engineering drawings, system counts, and manufacturer specs.

- Consolidate soft goods (harnesses, lanyards, SRLs) ⮕ Keep them all in one accessible location.

- Ensure clear and safe access ⮕ Unlock doors, remove obstacles, and provide any needed lift equipment.

- Bundle services if possible ⮕ Schedule lifeline inspections alongside crane or rigging inspections for cost savings.

- Communicate site-specific requirements ⮕ Let us know if safety orientation, special PPE, or escorting is needed

🛠️ Optional — For P.E. Inspections:

- Be ready to discuss missing engineering documentation or custom-built systems.

- If aerial inspections or drones are required, flag this in advance.

The more prepared you are, the faster and more efficient your inspection will be — and the less likely you are to incur unexpected costs.

Why Mazzella?

Mazzella provides comprehensive fall protection inspections that help you stay compliant, reduce risk, and protect your workers.

🧠 Trusted Technical Expertise

- Inspections performed by trained fall protection inspectors or licensed Professional Engineers (P.E.s).

- Ability to inspect lifelines, harnesses, anchors, trolleys, and more.

- Inspectors can also perform crane, rigging, or racking inspections in the same visit.

🧰 Complete Service Capabilities

- Inspection, installation, repairs, training, and product supply from one provider.

- National service coverage helps reduce travel and scheduling costs.

- Soft goods can be included when part of a larger inspection scope.

📋 Efficient, Documented, and Compliant

- Inspections meet OSHA 1910/1926, ANSI Z359, and OEM standards.

- Digital reports provided after inspections.

- Master Service Agreements (MSAs) available for large or multi-site accounts.

Whether your system is pre-engineered, custom-built, or undocumented, Mazzella’s inspection programs are structured to match your environment and compliance requirements.

![Fall Protection Harness Inspection Field Reference [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2022/05/resource-download-fall-protection-harness-inspection-guide.jpg)

![Cable SRL Inspection Field Reference [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2023/05/resource-download-cable-SRLs-field-reference-inspection-guide.jpg)

![Fall Protection Synthetic SRL and Lanyard Inspection Field Reference [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2022/06/resource-download-fall-protection-SRL-lanyard-inspection-removal-criteria-poster.jpg)

![Job Safety Analysis & Working at Height Risk Assessment [Bundle]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-fall-protection-jsa-whra-bundle-0324.jpg)

![Top 10 Safety Tips for Working at Height [Infographic]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-top-10-safety-tips-for-working-at-height-infographic-0324.jpg)