Description

Features and Benefits:

- Very high heat resistance

- Zero creep

- Very low stretch

- Very high strength

- Soft hand

- Torque free

- Easy splicing

Applications:

- Theatrical rigging lines

- Utility winch and pulling lines

- Recreational vehicle winch lines

- Tower guy wires

Certifications:

- ABS

- DNV-GL

| Nominal Diameter (inches) |

Size (circ in.) |

Approximate Weight (lbs/100ft) |

Minimum Tensile Strength Spliced Rope (lbs) |

Minimum Tensile Strength ISO Unspliced Rope (lbs) |

|---|---|---|---|---|

| 1/8 | 3/8 | 0.6 | 2,520 | 2,800 |

| 3/16 | 9/16 | 1.3 | 5,040 | 5,600 |

| 1/4 | 3/4 | 1.9 | 7,335 | 8,200 |

| 5/16 | 15/16 | 3.2 | 11,700 | 13,000 |

| 3/8 | 1-1/8 | 4.3 | 16,200 | 18,000 |

| 7/16 | 1-1/4 | 6.7 | 25,200 | 28,000 |

| 1/2 | 1-1/2 | 8.3 | 29,700 | 33,000 |

| 5/8 | 1-3/4 | 13.5 | 45,000 | 50,000 |

| 3/4 | 2-1/4 | 19.3 | 59,000 | 65,600 |

| 7/8 | 2-3/4 | 25.3 | 76,000 | 84,400 |

| 1 | 3 | 31.1 | 92,000 | 102,200 |

| 1-1/8 | 3-1/2 | 42.3 | 123,000 | 136,700 |

| 1-1/4 | 3-3/4 | 48.1 | 139,400 | 154,900 |

Sizes available up to 8-1/4″ diameter (200 mm) and 4,900,000 lbs strength. Tensile Strengths are determined in accordance with Cordage Institute 1500, Test Methods for Fiber Rope. Weights are calculated at linear density under standard preload (200d2) plus 4%. See reverse side for application and safety information.

Technical Information

Specific gravity: 1.39*

Thermal decomposition: 932°F (500°C)

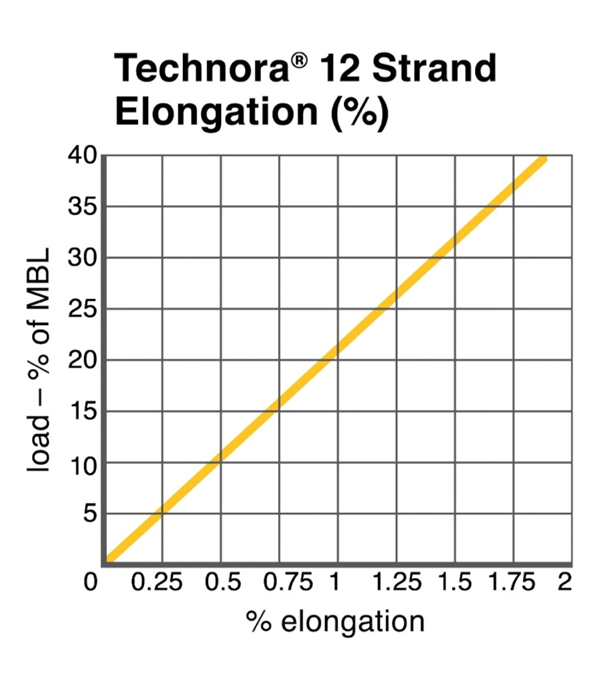

Elongation at break: 4–5%

Fiber water absorption: 0%

UV resistance: moderate

Abrasion resistance: good

* Value based on data supplied by the fiber manufacturer for new, dry fiber