Description

Features and Benefits:

- Highest strength

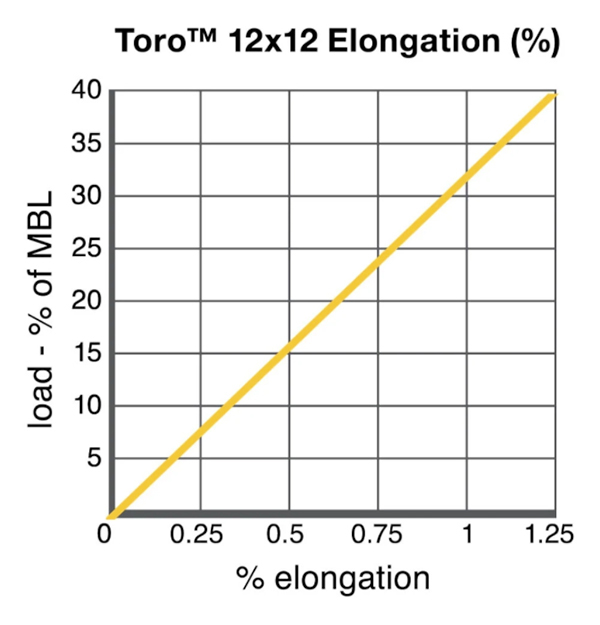

- Very low stretch

- Lightweight

- Soft hand

- Torque free

- Easy splicing

- Floats

- Long lengths available

- High flex fatigue and abrasion resistance

- Moderate UV resistance

- Easy to inspect and repair

- Neutrally buoyant in water

Applications:

- Replacement for wire rope heavy lift slings

- Tug vessel assist lines

- Vessel mooring lines

- Offshore working ropes

- Lashings

Certifications:

- ABS

- DNV-GL

| Nominal Diameter (inches) |

Size (circ in.) |

Approximate Weight (lbs/100ft) |

Minimum Tensile Strength Spliced Rope (lbs) |

Minimum Tensile Strength ISO Unspliced Rope (lbs) |

|---|---|---|---|---|

| 1-5/8 | 5 | 62.0 | 245,000 | 272,100 |

| 1-3/4 | 5-1/2 | 72.3 | 284,300 | 315,800 |

| 2 | 6 | 94.9 | 369,900 | 410,900 |

| 2-1/8 | 6-1/2 | 108.9 | 423,900 | 470,900 |

| 2-1/4 | 7 | 121.3 | 470,100 | 522,200 |

| 2-1/2 | 7-1/2 | 147.9 | 569,400 | 632,600 |

| 2-5/8 | 8 | 163.8 | 630,300 | 700,200 |

| 2-3/4 | 8-1/2 | 182.4 | 698,400 | 775,900 |

| 3 | 9 | 215.4 | 819,000 | 909,900 |

| 3-1/8 | 9-1/2 | 233.2 | 886,500 | 984,900 |

| 3-1/4 | 10 | 253.5 | 961,300 | 1,068,000 |

| 3-1/2 | 10-1/2 | 290.7 | 1,095,300 | 1,216,800 |

| 3-5/8 | 11 | 314.1 | 1,184,300 | 1,315,700 |

| 3-3/4 | 11-1/2 | 338.7 | 1,273,100 | 1,414,400 |

| 4 | 12 | 383.5 | 1,435,200 | 1,594,500 |

| 4-1/8 | 12-1/2 | 407.0 | 1,523,400 | 1,692,400 |

| 4-1/4 | 13 | 433.4 | 1,618,600 | 1,798,200 |

Size: Diameter and circumference are nominal. A new unused rope in relaxed state will measure larger; loading and use compacts ropes, sets splices and lessens rope size.

Weights: Published weights of sizes 1-5/8″– 4-1/4″ diameter are calculated at linear density under stated preload (200d²) plus 4%.

Tensile Strengths: Tensile strength determined in accordance with Cordage Institute 1500‑02 Test Methods for Fiber Ropes and ISO 2307.

Technical Information

- Specific gravity: 0.98*

- Melting point: 284°F (140°C)

- Critical temperature: 150°F (65°C)

- Coefficient of friction: 0.09–0.12*

- Elongation at break: 3%–4%

- Fiber water absorption: 0%

- UV resistance: moderate

- Wet abrasion: superior

- Dry abrasion: superior

* Value based on data supplied by the fiber manufacturer for new, dry fiber