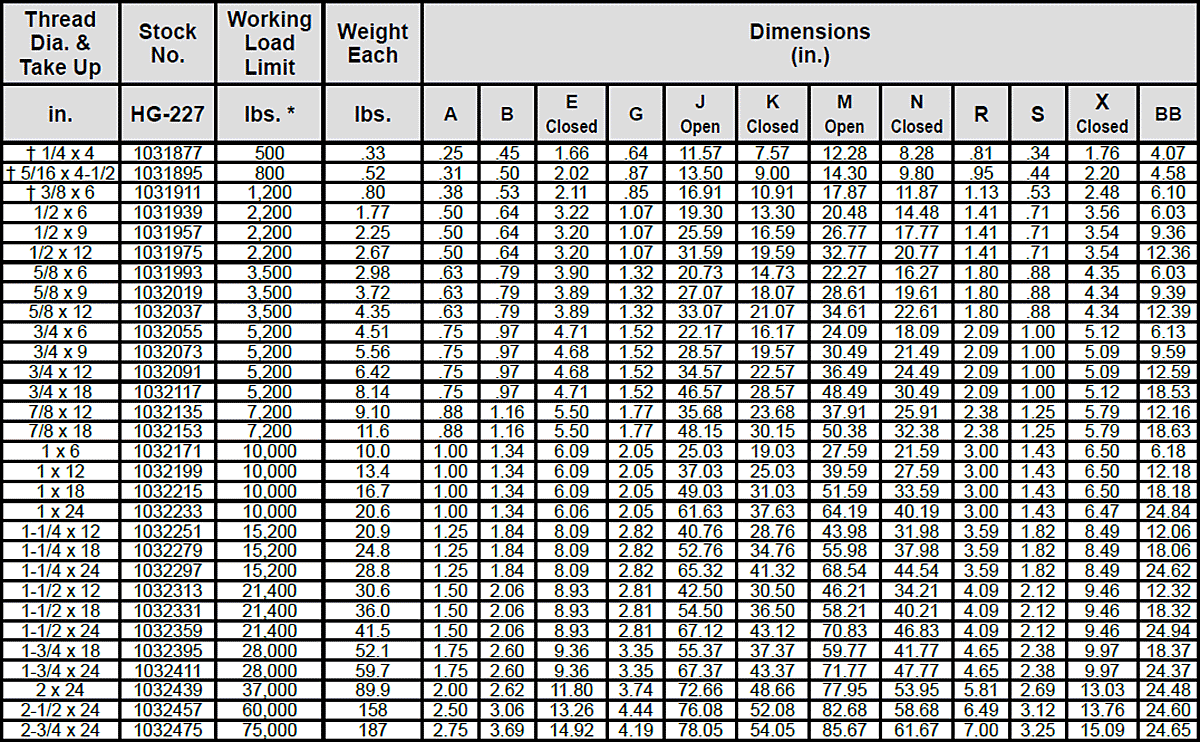

Description

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

† Mechanical Galvanized

Meets the performance requirements of Federal Specifications FF-T-791b, Type 1, Form 1 — CLASS 8, and ASTM F-1145, except for those provisions required of the contractor.

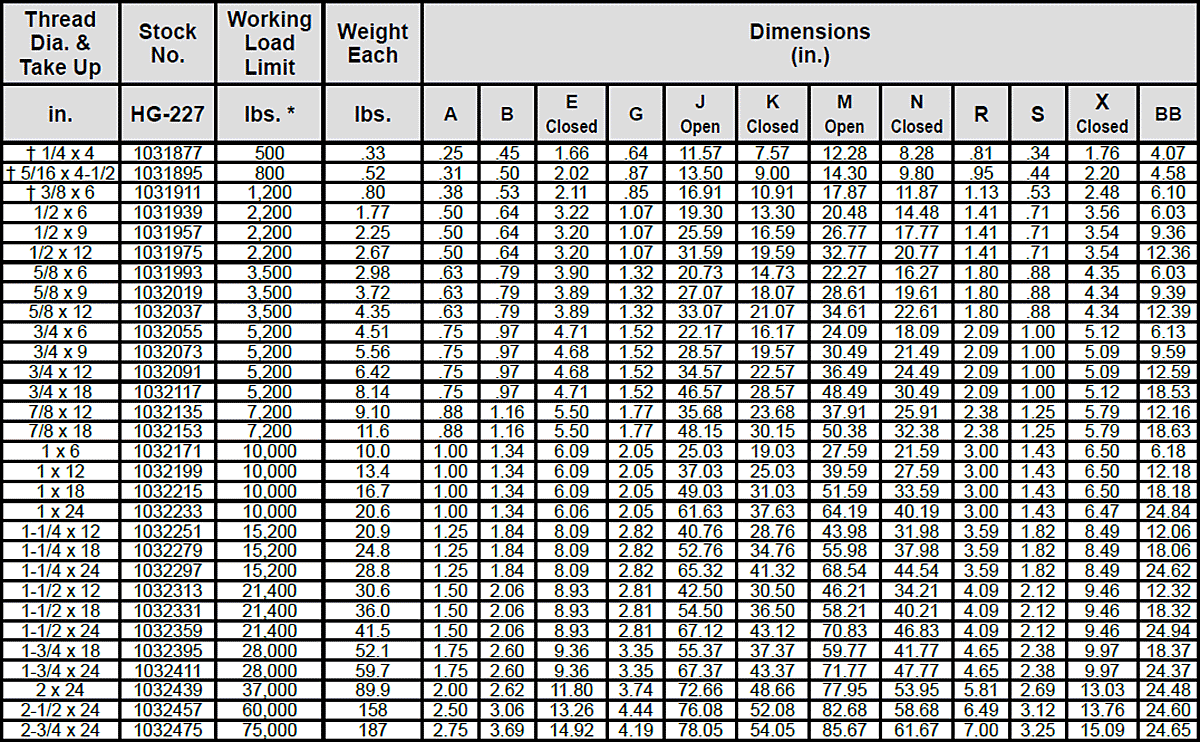

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

† Mechanical Galvanized

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.