Description

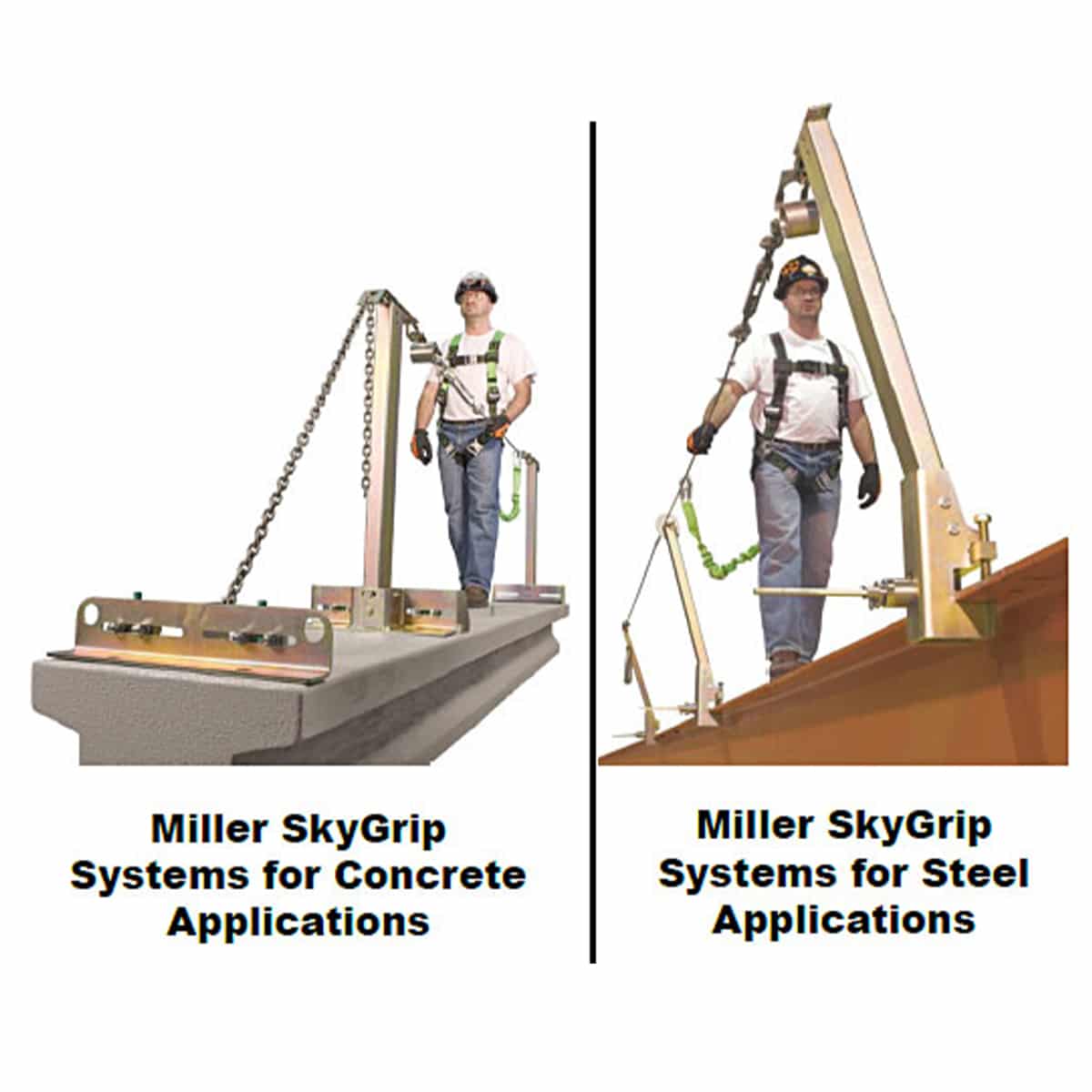

Miller SkyGrip Systems for Concrete Applications

Miller SkyGrip Temporary Horizontal Lifeline Systems for concrete applications feature unique stanchion adjustment that allows the anchorage to be repositioned, minimizing obstruction and increasing safety.

- Uniquely designed for angled adjustment—swings out of the way when placing deck-pans between beams (common in bridge construction)

- Slider bracket tensions tie-back chain to minimize fall clearance

- For concrete applications, bases can be positioned parallel or perpendicular to the beam.

- Three methods of attachment include:

– V-Grip rebar attachments (Rebar sizes 4 to 11) – Expansion anchor bolts (Purchased separately)

– Precast inserts (Purchased separately)

– Slider bracket assists with quick installation

– Angled adjustment

Complete system includes stanchions, tie-back brackets, chain connectors, slider brackets, energy absorber(s), line tension indicator, turnbuckle, cable and hardware. Attach to rebar, coil inserts or concrete expansion bolts.

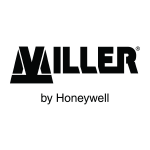

Miller SkyGrip Systems for Steel Applications

Miller SkyGrip Temporary Horizontal Lifeline Systems for steel applications are compact and lightweight for easy installation, while providing greater user mobility for increased productivity.

- Two base / crossbar adjustment systems accommodate wide range of steel beam sizes

- Low-profile crossbar—reduces trip hazard

- Quick grip above-the-beam adjustment—patent-pending design allows for easy one-person installation and dismantle, increasing safety and productivity

– Position crossbar

– Fine-tune adjustment

– Stanchion installation complete

– All adjustments above-the-beam

Complete system includes stanchions, energy absorber(s), line tension indicator, turnbuckle, cable and hardware.

- Systems with Standard Base—Fit beam flanges 4″ to 18″ wide up to 2-1/4″ thick.

- Systems with Large Base—Fit beam flanges 12″ to 36″ wide and to 2-1/4″ to 3-3/8″ thick.