Description

- Forged suspension ring acc. to EN 1677, grade 80, electromagnetic crack detected, pink powder coated; meets the requirements of the appropriate safety authorities.

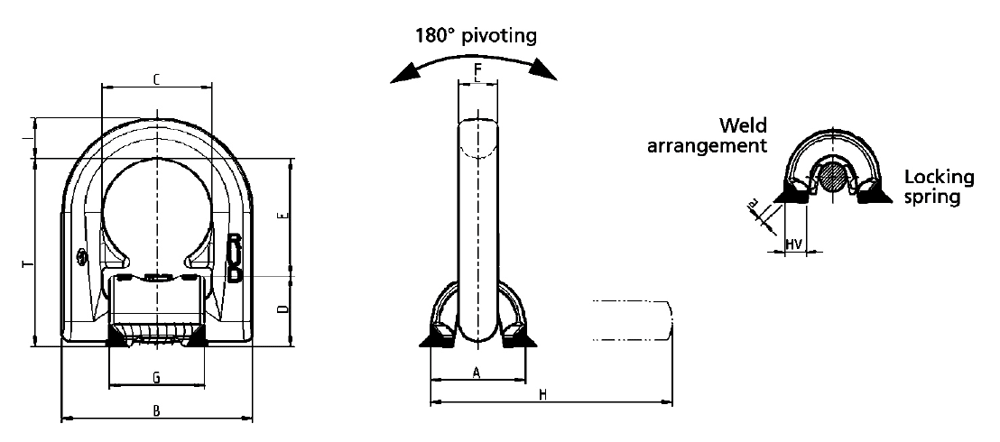

- The welding block has been forged of material 1.0570 (St 52-3) and clearly stamped with the permissible WLL. The patented distance lugs assist in achieving the correct root weld.

- Important: By the special weld design (continuous HV), therequirements of DIN 18800 are fulfilled, i.e., a closed weld avoidscorrosion and thus suitable for outdoor use

- Distinctive features for type LBS-U: A protected spring maintains the load ring in every required position. The parts are assembled in such a way that they remain captive.

- The spring reduces vibration induced noise.

Attention: Refer to RUD user welding instructions.

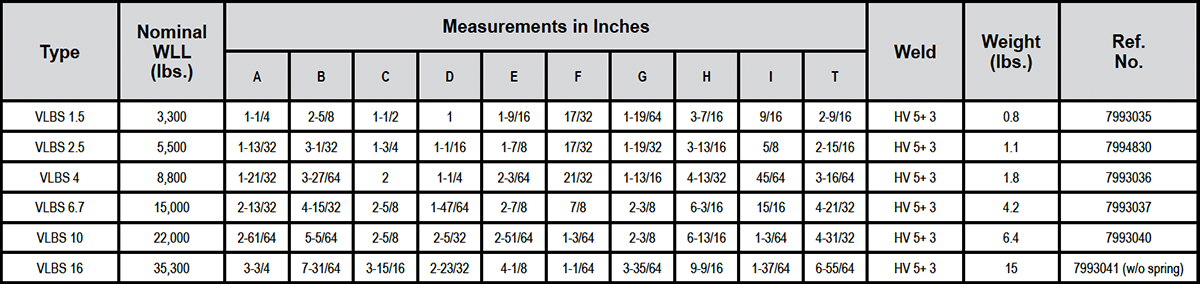

The WLL (Working Load Limit) is listed at the nominal value (worst case scenario) unless otherwise specified.