Year in Review: The 10 Best Lifting and Rigging Articles of 2018

If you missed out on some of our articles, or you aren't yet a blog subscriber, then we have you covered. This article will catch you up on the ten most popular and best-performing lifting and rigging articles of 2018.

No matter what industry you’re in, there are plenty of products, procedures, and standards that you need to familiarize yourself with in order to do your job safely and effectively. If you and your team use rigging products and lifting equipment to move and handle loads, then you know how complicated it can be to stay on top of industry standards and regulations.

That’s why we originally created the Lifting & Rigging Learning Center. We’re dedicated to regularly releasing new blog articles, videos, podcasts, and downloadable resources to help answer the questions you might have about material handling, rigging practices, overhead cranes, fall protection, and so much more!

Our goal has always been to partner with industry experts and release educational resources designed to help you:

- Make educated decisions when purchasing lifting or rigging equipment for your specific application

- Understand industry standards from OSHA, ASME, ANSI, CMAA, etc.

- Keep your lifting and rigging programs in compliance with industry standards

- Improve the safety and efficiency of your workplace and practices

In 2018, we’ve grown to over 500 blog subscribers and over 400 YouTube subscribers. Our blog articles were viewed over 100,000 times and we have over 100,000 minutes of video view time on YouTube!

If you’ve read one of our articles, watched any of our videos, listened to a podcast, or downloaded anything from our website, we sincerely thank you. We continue to create new content because we get such great feedback from those who read, watch, or listen.

If you missed out on some of our articles, or still need to subscribe to the blog, then we have you covered. This article will catch you up on the ten most popular and best-performing lifting and rigging articles of 2018.

The Best Lifting and Rigging Articles of 2018

How to Measure Span and Runway Length for an Overhead Crane

While a crane manufacturer will come in to your facility and gather all of the measurements that they need to put a proper quote and specification together, it’s also a good idea for you as the consumer to be informed about the design and specification requirements for your new overhead crane. Understanding how a new crane will fit into your existing facility, or how the structural and design factors of an existing runway and support structure can be utilized, will help you double-check their bids.

The better informed you are as a customer, the smoother the design, consultation, and quotation processes will be. Knowing the specifications and requirements for your crane system gives you more power and knowledge you can use to make an informed purchasing decision. The more informed you are, the easier it will be to select a manufacturer that will provide you with a crane system that is a long-term, safe, and efficient solution.

In this article we cover:

- Tools/materials you’ll need

- How to measure the crane’s runway beams

- How to measure the crane’s rail size

- Measuring crane span

- Measure for crane runway length and distance between supports

- Identifying obstructions and measuring building clearance

- Duty cycle determinations

What Is Wire Rope? Understanding the Specifications and Construction

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. However, selecting the proper wire rope for your lifting application requires some careful thought. Different configurations of the material, wire, and strand structure will provide different benefits and characteristics for the lifting application.

In this article, we cover:

- How wire rope is a machine with many moving parts

- Components of wire rope

- Wire rope construction

- Different types of wire rope and unique characteristics

Overhead Crane Electrification: NEC 610.61 Grounding Requirements

Did you know that cranes using 3-bar conductor electrification are no longer in compliance with electrification standards? Many business owners may not realize that their older electrification systems are outdated, or they mistakenly think they’re in compliance because of a “Grandfather Clause.”

Prior to 2005, overhead cranes using conductor bar electrification only needed three bars—a positive, negative, and neutral to power their overhead crane equipment. The metal wheels on the bridge trolley and hoist trolley provided a ground through contact with the metal track they run on.

In 2005, that changed. Revisions were made to National Electrical Code (NEC) grounding requirements for overhead cranes and stated that a separate grounding conductor was required in place of the metal-to-metal connection provided by the wheels and track.

In this article, we cover:

- The purpose of a ground in an electrical circuit

- Changes to NEC 610.61 Grounding Requirements

- OSHA’s interpretation of their electrical and grounding standards

- Your options for upgrading or modifying a 3-bar conductor electrification system for compliance

How to Inspect Wire Rope Slings According to ASME B30.9 Standards

Do you know who is supposed to be inspecting your wire rope slings? More importantly, do you know how often they’re inspecting them? OSHA and ASME have different inspection requirements, frequencies, and removal criteria for each type of sling—including alloy chain slings, synthetic slings, metal mesh slings, and wire rope slings.

When you understand what is required for your wire rope slings to meet ASME standards, you’ll in turn be able to help ensure the safety of the users, help extend the service life of the slings, and help reduce unnecessary equipment repair costs and loss of production due to equipment downtime.

In this article, we cover:

- Who performs inspections and how often do they occur?

- What’s required on a wire rope sling identification tag?

- Basic inspection criteria for wire rope slings

- Disposal of damaged or failed wire rope slings

- How to inspect wire rope slings

- Best practices for maintaining wire rope slings

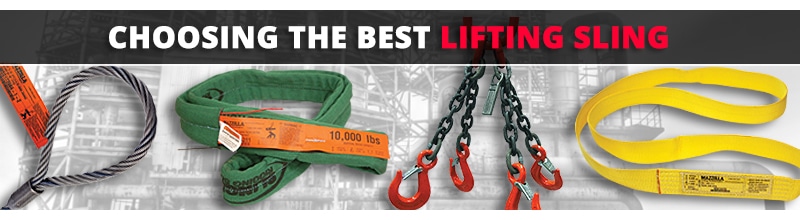

Choosing the Best Lifting Sling: Wire Rope vs. Chain vs. Synthetics

Chain slings, wire rope slings, web slings, roundslings, synthetic rope, and metal mesh slings can all be used to safely and efficiently lift, move, and position a load. But, choosing the right type of lifting sling is dependent on a complete understanding of the application, the environment it’s being used in, and how the sling will be used to support and lift the load.

In this article, we explore the construction, applications, advantages, and disadvantages of the following types of slings:

- Wire rope slings

- Alloy chain slings

- Synthetic web slings

- Synthetic roundslings

- Synthetic rope slings

- Metal mesh slings

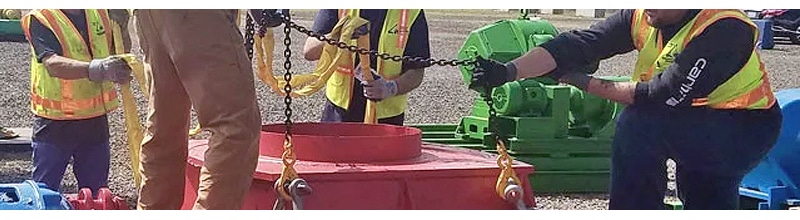

Lifting and Rigging Solutions for Die Handling and Automotive Stamping

Over the years, automation has eliminated a number of production processes that required skilled labor and manual lifting and rigging procedures. In many manufacturing environments, technology controls these processes and procedures almost entirely—with minimal human assistance—particularly in the automotive industry.

However, one area of manufacturing that still relies on skilled labor to perform lifting and rigging procedures is the process used for automotive stamping. Here, flat sheet metal is loaded into a press where a tool and die form the metal into a finished shape. In these shops, dies can be handled with traditional rigging like lifting slings and rigging hardware. Or, specially-engineered devices can be used in conjunction with overhead cranes to provide safer and more precise and reliable handling of the dies for service and maintenance.

In this article, we cover:

- Assessing your lifting equipment and practices

- Using the proper rigging hardware

- Selecting the proper lifting slings

- Specifying the duty cycle of an overhead crane

- Using below-the-hook lifting devices

- Implementing a fall protection program

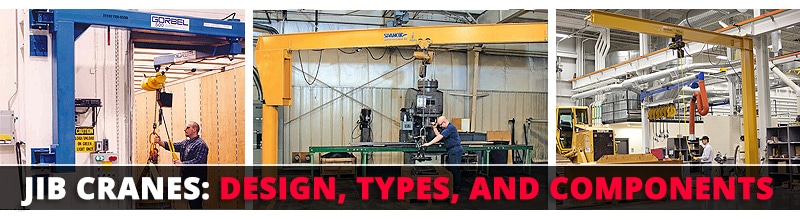

What Is a Jib Crane? A Look at the Design, Types, and Components

Do you feel like your workers are struggling to meet production quotas, or you’re missing that final piece to really streamline your production process? If so, you may want to consider a jib crane.

Installing a jib crane, or a series of jib cranes, can increase production and improve workplace safety at your facility by reducing workplace injuries. Jib cranes are perfectly designed to handle high-volume lifts and provide an ergonomic means of moving material within a work cell or in conjunction with an existing overhead crane system.

In this article, we cover:

- Jib crane design and components

- Different types of jib crane systems, including:

- Freestanding jib cranes

- Foundationless jib cranes

- Mast type jib cranes

- Wall-mounted jib cranes

- Articulating jib cranes

6 Most Common Problems Found During a Rigging Gear Inspection

Do you hear the words “rigging inspection” and immediately begin breaking out in a cold sweat? Are you afraid a rigging inspection is going to disrupt your production and set you back when you have to replace all of the gear that fails inspection?

It’s not a stretch to say that some companies are more proactive in training their employees and inspecting their rigging gear than others. If you were to compare your most recent rigging inspection report to a similar company in your industry, how would you compare when it comes to failed equipment and compliance?

In this article, we cover:

- Problems with sling identification

- Problems with synthetic slings

- Problems with alloy chain slings

- Problems with wire rope

- Problems with rigging hardware

- Problems with below-the-hook lifters

What Is a Gantry Crane? A Closer Look at the Different Types and Design

The term “gantry crane” tends to get thrown around a lot in the material handling industry. We often find that when folks say gantry crane, they’re often referring to an overhead bridge crane system. A gantry crane and bridge crane are actually very different types of overhead cranes.

Gantry cranes are perfectly designed to handle high-volume lifts and provide an efficient means of lifting or moving heavy loads through a yard, fabrication shop, or general manufacturing/warehousing environment.

In this article, we cover:

- The definition of a gantry crane

- Different types of gantry cranes

- Applications where gantry cranes are used

- Gantry crane design considerations

OSHA Definitions of Competent, Qualified, Designated & Certified Persons

Do you know what the difference is between Competent, Qualified, Designated, and Certified? These terms are frequently used in everyday conversation, but as it relates to the rigging and lifting industry, OSHA and ASME have very specific definitions and implications for each one.

Trying to keep track of all of this can make your head spin. For this article, we consulted with some of the most senior-level employees at Mazzella Companies, who have 20-30+ years of experience in the lifting and rigging industry.

In this article, we cover:

- OSHA and ASME definitions and requirements for each term

- What are the qualifications for each terms?

- Who is responsible for determining what those qualifications are?

Wrapping it Up

Again, thank you for everyone who has read, watched, listened, or downloaded any piece of educational content that we’ve put together. Thanks to those who have liked, shared, or commented on any piece we’ve posted on any of our channels, including LinkedIn, Facebook, Twitter, and Instagram.

For 2019, we’d love to hear from you…if you have any ideas for future topics, or have any questions you’d like us to answer, please reach out to us at any time. You can contact us directly at marketing@mazzellacompanies.com.

From all of us at Mazzella, we want to wish you a happy holiday season, Happy New Year, and a productive and prosperous 2019!