Synthetic Web Slings: 6 Things You Should Know Before Buying

We often find that when customers want to order a new web sling, they aren’t aware of all the different configurations that exist and may not know how to order a direct replacement. Our goal is to help you understand some of the terms used with synthetic sling construction and what information you can provide during your next order experience.

Synthetic web slings are one of the most popular types of lifting slings on the market. They’re strong enough to support heavy loads and are versatile enough to be used in several different applications and industries.

Web slings are also popular because they’re relatively inexpensive—if one gets damaged or gets removed from service after an inspection, replacement slings can be easily found at a reasonable price.

We often find that customers contact us to order a new web sling, they aren’t aware of all the different configurations that exist and may not know how to order a direct replacement. Even if they have the sling with them, it can be difficult to understand the part number on the tag, or decipher the abbreviations and specifications on the tag to order a direct replacement.

In addition to the weight of the load you’ll be lifting, there there are several things you’ll need to know to get a web sling that meets the needs of your lifting application, including:

- Material – polyester or nylon

- The type of eye or fitting needed on each end

- The number of plies in the body

- Width of the sling body

- Overall length of the sling

- Additional cut, wear, or abrasion protection

Our goal for this article is to help you understand some of the terms used with synthetic sling construction and what information you can provide when requesting a quote during your next order experience.

Synthetic Web Sling Material – Nylon or Polyester

One of the first things you’ll need to determine is if you want or need a web sling made from nylon or polyester material. For most lifting applications, the webbing material won’t make a difference in the quality, capacity, or strength of the web sling. However, in certain applications you may have to consider the stretch of the sling at capacity, and resistance to acids or bleaches in a chemically-active environment.

Polyester web slings are used primarily in conditions where acid is present and minimum stretch is desired. Polyester is unaffected by common acids and bleaching agents, but the material is unsuitable for use in conditions where concentrated sulfuric acid or alkaline are present. Polyester is also unsuitable in locations where temperatures exceed 194°F. Stretch of a polyester web sling at rated capacity is approximately 3%.

Nylon is unaffected by grease and oil and the material has excellent chemical resistance to aldehydes, ethers, and strong alkalis. However, nylon slings are not suitable for use with acids and bleaching agents, or at temperatures in excess of 194°F. The stretch of a nylon sling at capacity is approximately 8-10%.

Polyester and nylon webbing materials have different chemical resistance properties. Please refer to the chart below for guidelines on polyester or nylon web slings in specific chemically-active environments:

| Nylon | Polyester | |

| Acids | No | * |

| Alcohols | Yes | Yes |

| Aldehydes | Yes | No |

| Strong Alkalis | Yes | ** |

| Bleach Agents | No | Yes |

| Dry Cleaning Solvents | Yes | Yes |

| Ethers | Yes | No |

| Halogenated Hydrocarbons | Yes | Yes |

| Hydrocarbons | Yes | Yes |

| Ketonnes | Yes | Yes |

| Oils (Crude) | Yes | Yes |

| Oils (Lubricating) | Yes | Yes |

| Soaps & Detergents | Yes | Yes |

| Water & Sea Water | Yes | Yes |

| Weak Alkalis | Yes | Yes |

* Disintegrated by concentrated sulfuric acid

** Degraded by strong alkalis at elevated temperatures

Different Types of Synthetic Web Sling Configurations

Web slings come in several different configurations, including:

- Single or multi-leg bridle assemblies

- Eyes formed on both end of the sling

- An endless or infinite loop configuration (similar to a synthetic roundsling)

- With fittings on both ends of the sling

Eye and Eye (EE) Web Slings

Eye and eye web slings have eyes sewn into both ends of the sling. Eye and eye slings can be configured with either a flat eye or twisted eye on both ends. A flat eye can be used in a choker hitch, basket hitch, or vertical hitch, while a twisted eye sling has eyes that are twisted 90° to form a better choker hitch.

Endless / Infinite Loop (EN) Web Slings

Endless web slings can be used in all three types of sling hitches. The sling can be rotated throughout its service life to minimize wear and avoid repetitive use damage.

Reverse Eye (RE) Web Slings

A reversed eye web sling is actually an endless sling with butted edges sewn together to double the sling width. Reversed eye slings typically have reinforced eyes and wear pads on both sides of the body for premium resistance to wear and abrasion.

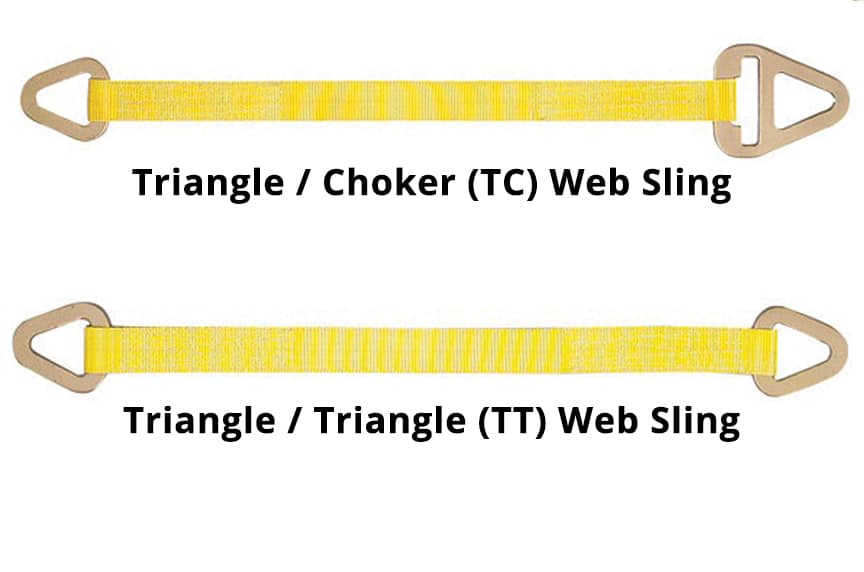

Triangle / Choker Fittings (TC) Web Slings

This type of sling is configured with a triangle and choker fitting on either end. These types of slings are typically used in a choker hitch and can be used in vertical and basket hitches as well.

Triangle / Triangle Fittings (TT) Web Slings

This type of sling is configured with a triangle fitting on each end. These types of slings are normally used in a basket hitch, but can also be used in a vertical hitch. They cannot be used as a choker.

Wide Lift (LT) Web Slings

Wide lift slings have a wider width and more surface area than traditional web slings and are used in a basket hitch. This wider surface provides extra load stability for bulky loads and added protection for fragile loads or finished surfaces.

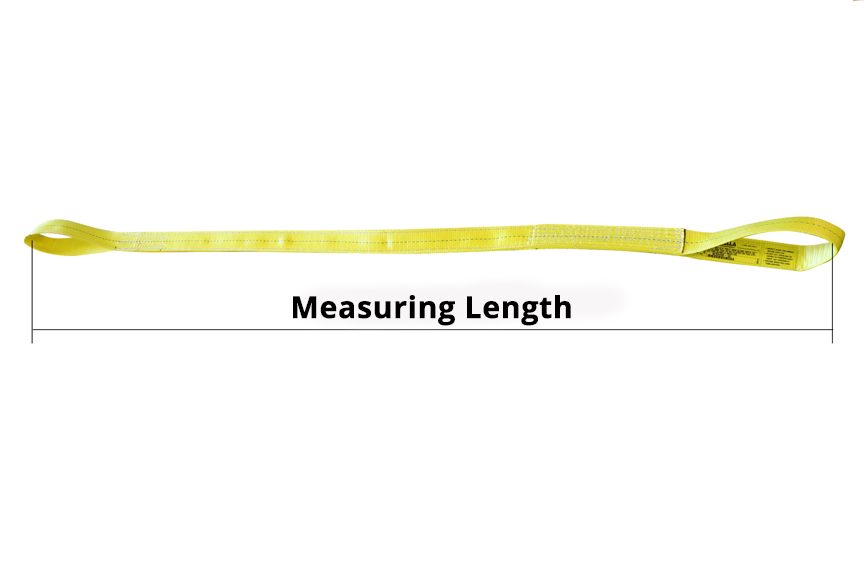

Web Sling Length

Synthetic web slings can come in virtually any length. Many manufacturers offer standardized product offerings, including incremental increases in length ranging anywhere from 2 feet to 20 feet. However, it’s also common for manufacturers to offer customized sling lengths so you can get a web sling designed to the exact specifications of your application.

When determining sling length, measure from the top load-bearing point to the bottom load-bearing point. An eye and eye sling length is measured from tip to tip of the eyes. Multi-leg sling assemblies, or single-leg slings with fittings, are measured from the load-bearing point of any rings, hooks, or fittings.

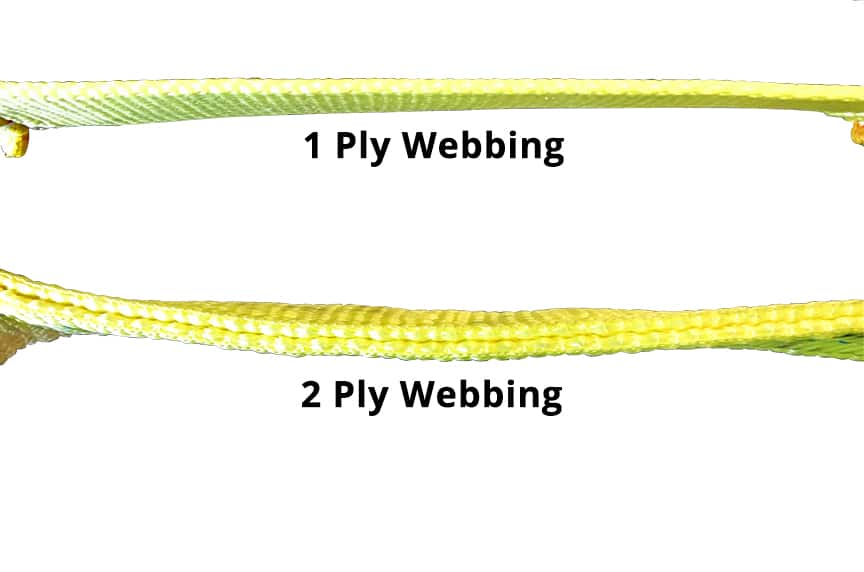

Number of Plies

The ply number, or number of plies, refers to the layers of webbing that make up the body of the sling. A web sling is generally available in 1, 2, 3, or 4 ply configurations. Adding more plies to the sling provides added strength to the body of the sling.

For example, if the breaking strength of a 1 ply web sling = X, then…

- The breaking strength of an equivalent 2 ply web sling = 2X

- The breaking strength of an equivalent 3 ply web sling = 3X

- The breaking strength of an equivalent 4 ply web sling = 4X

Web Sling Width

With a wider sling body, the load is distributed over a larger sling surface area. Wider width slings provide greater protection to delicate or finished surfaces, as well as better load balance and control for large or heavy loads. Typical standard sling lengths can range anywhere from 1” to 12” in width. Larger sizes are available as special-orders, or in a wide lift sling configuration.

Web Sling Protection

There are several different ways that you can incorporate added wear, cut, and abrasion protection to a synthetic web sling. When you know how to properly maintain and care for your slings, you can help extend the service life of the product and get a better return on your investment.

These are some of the web sling protection options that can be added during the manufacturing process, or purchased as an add-on:

- Sling wear pads can be sewn into the webbing material at specific wear points along the sling body or in the eyes

- Edge guards can be sewn along the edges of the sling to offer added protection at critical spots that are prone to abrasion, wear, or cutting

- A sleeve or tube slides over the body of the sling and protects both sides of the sling body while in use

- A wrap, similar to a sleeve, is sewn onto the body of the sling to protect the edges and lifting of the surface from wear or cutting

- A special coating can be added to the webbing material during the manufacturing process. This protects against moisture and dirt penetration and also helps reduce abrasion.

- Special types of shackles are designed specifically for use with web slings. A wider sling bearing surface results in an increased area for load distribution and allows for 100% W.L.L. efficiency.

Always make sure that you follow ASME B30.9 guidelines when inspecting your web slings. Regular inspection of your slings—especially before each use—is crucial to help identify any damage or irregularities that may compromise the strength and integrity of the sling. Web slings are especially susceptible to damage from edges, rough surfaces, heat, chemical exposure, and UV light degradation!

Wrapping it Up

If you want to switch from heavy wire rope or chain to a comparable style web sling, or you’re replacing a sling that’s been damaged or failed inspection, here’s what you’ll need to know to order the correct style sling for your lifting application:

- Working Load Limit

- Sling webbing material

- Number of legs (single or multi-leg assemblies)

- Sling configuration (eye style or fitting style on each end)

- Sling length

- Number of plies

- Sling width

- Additional cut, wear, or abrasion resistance

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We have more than 30 locations across the east coast, midwest, and central and southern portions of the United States—fully stocked with different sizes and configurations of rigging products for your next project.

We’d appreciate the opportunity to help you make the best investment decisions for your lifting and rigging product needs. If you’d like a quote for your next lifting project, or want to schedule a consultation on solutions for your rigging application, please contact a Lifting Specialist today.

Slings & Assemblies

Are you looking for lifting slings, including chain, wire rope, synthetic flat web, metal mesh, cordage, and single-path / high-performance roundslings? We can help provide the right sling for your needs!

Additionally, if you need sling assemblies—both large and small, we can manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Contact us today to get the lifting slings and assemblies you need!

Learn more about lifting slings and assemblies!

Copyright 2019. Mazzella Companies.