Wire Rope Slings: What Does Import and Domestic Really Mean?

When sourcing wire rope or wire rope slings for your next lifting project, make sure that you do your research and understand where the raw materials came from and where the final product was assembled.

In the lifting and rigging marketplace, there are plenty of options when it comes to buying wire rope and wire rope slings. Wire rope slings can be categorized as either domestic, imported, or fall into a confusing grey area where the product may be labeled as “made in the USA” or “American-made” but are manufactured from or contain imported materials.

Over the years, the stigma that was attached to import vs. domestic rigging products has begun to fade away. Today, there are many imported rigging products in the market that are quality pieces, safe to use, and meet the same federal specifications as domestic rigging products. If you’ve taken the steps to vet your supplier, and your supplier is vetting their manufacturer, then you’ve done a good job of covering your bases.

In this article, we’ll break down the following terms and what that means in terms of the country of origin for the raw materials and components, as well as the location where they’re assembled:

- Domestic wire rope slings

- Wire rope slings made in the USA

- Import wire rope slings

Domestic Wire Rope Slings

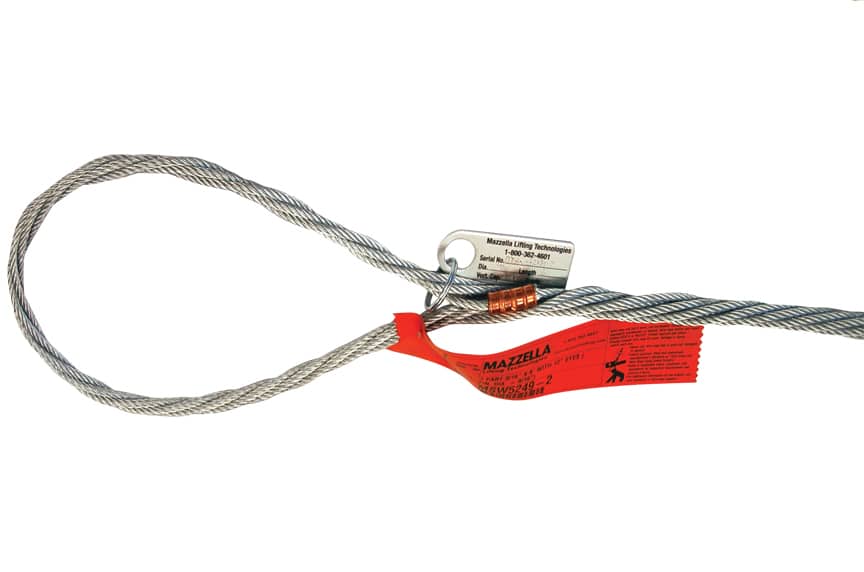

A domestic wire rope sling is a sling that uses components (such as the wire rope and sleeves) from raw material made in the USA. The labor to make these wire rope slings is also performed in the USA.

One advantage to using a domestic wire rope sling is that companies who source their materials domestically and make their rigging products domestically are more equipped to handle special or customized products. Domestic manufacturers tend to have more of an infrastructure in place that allows them to implement quality control programs, make smaller-batch production runs, and can provide their customers with more customized solutions.

Domestic wire rope may not be the lowest price option, but companies who make their wire rope slings domestically can offer value-added services like engineering, R&D, in-house batch testing, and customized product offerings.

Wire Rope Slings Made in the USA

This is where it gets a little misleading in our industry. Some companies may use the term “made in the USA” because the labor to make the wire rope sling is performed in the USA. Essentially, the finished good (the wire rope sling) is assembled in the USA and that’s the only claim that can be made.

In similar instances, you’ll see “Made in the USA” claims made by some of the major auto manufacturers who have assembly plants located in the USA. They may manufacture the majority of their car components overseas, but the actual assembly of the vehicle is performed here in the United States by American workers.

The important difference between a true domestic wire rope and a wire rope that is “made in the USA,” is that the finished version of the sling can be assembled in the USA using raw materials (such as the wire rope and sleeves) that are either sourced entirely overseas, or could be a combination of domestically-sourced and imported materials.

To ensure that a wire rope sling meets the true definition of a domestic product, the raw materials should be made in the USA and the labor to make the finished part should be performed in the USA. If import wire rope is used, then the sling should be considered an import product—not a domestic product.

You can request a “certificate of conformance” from the supplier to make sure that the wire rope slings that you’re purchasing meet the same federal specifications as those required for domestic-made wire rope.

Import Wire Rope Slings

Import wire rope slings are defined as slings that are manufactured and assembled overseas or outside of the USA. These slings use raw materials (such as wire rope and sleeves) that are made in a country other than the USA. The labor to make these wire rope slings is performed in a country outside of the USA as well. They are then shipped here to the United States in a shipping container and are considered import products.

Many rigging shops offer imported wire rope slings in the most common sizes and configurations and at a lower price. Overseas manufacturers traditionally focus on the most common sizes and configurations, and run large production batches. This allows them to run their business with little to no overhead and keep their costs down—savings that are then passed along to the end-user.

While the quality of imported wire rope slings has improved with the spread of modern manufacturing methods and quality control programs, there are still some overseas factories using antiquated technologies and have little to no oversight on quality and testing.

Before you buy an import rigging product, ask the distributor if they or someone from their company has been to the facility making their equipment. If they say no, simply don’t buy it. If a distributor has visited the facility that is producing their rigging products, it should tell you that they are vetting their import suppliers and care about the people that are using their products, as well as the people making them.

What to Look for When Considering Import Wire Rope

When deciding on whether you want to use domestic or import wire rope slings for your company’s lifting program, consider the following:

- Make sure that imported wire rope slings have markings in accordance with federal standards and ask for a certificate of conformance from the supplier.

- Make sure the distributor has visited the facilities that produce their import wire rope and has properly vetted them.

- Make sure the wholesaler/distributor has adequate Product Liability Insurance. Even if the specific overseas manufacturer has liability insurance and an incident were to occur, it is nearly impossible to collect on any claim.

- Make certain that your distributor has products made to their specifications, not the manufacturer’s. This promotes consistent quality and lessens the liability.

- Make certain that your wholesaler / distributor does not buy through a Broker. Buying through a Broker can often times lead to mixed product of varying quality from multiple manufacturing facilities.

- Make sure the import product supplier has a product traceability program in place.

- Make sure the distributor conducts their own inspection and testing in-house.

Wrapping it Up

When sourcing wire rope or wire rope slings for your next lifting project, make sure that you do your research and identify whether the product that you’re buying is truly a domestic-made product, was assembled in the USA using materials or components from overseas, or was manufactured and assembled in an overseas facility.

Most importantly, before you buy an imported or domestic wire rope, make sure that the product was properly batch tested. Importers that vet foreign manufacturers should not rely solely on their supplier, and should always conduct their own set of in-house tests and inspection once they receive the shipment from the supplier.

At Mazzella, we sell the highest-quality import and domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and imported rigging and lifting products to suit your lifting needs.

If you have questions about wire rope slings or are looking for rigging equipment for your next lifting project, contact a Lifting Specialist at a Mazzella location near you.

Slings & Assemblies

Are you looking for lifting slings, including chain, wire rope, synthetic flat web, metal mesh, cordage, and single-path / high-performance roundslings? We can help provide the right sling for your needs!

Additionally, if you need sling assemblies—both large and small, we can manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Contact us today to get the lifting slings and assemblies you need!

Learn more about lifting slings and assemblies!

Copyright 2017. Mazzella Companies.