Are Twin-Path® Slings Worth the Extra Cost?

Learn about the biggest factors affecting the cost of a Twin-Path Sling, including patented technology and unique offerings.

The Twin-Path® sling, designed by Slingmax Rigging Solutions, is one of the most popular high-performance roundslings on the market, and for good reason. They are lightweight, they have a high lifting capacity, they are repairable, and they are backed by years of engineered data and testing.

However, Twin-Path® slings are not known for being inexpensive, especially compared to other traditional lifting slings. For many riggers, paying several hundred dollars for a synthetic lifting sling seems ridiculous. Historically, synthetic roundslings are something you buy cheap and discard the second they get damaged.

However, are you actually saving money constantly purchasing cheap lifting slings, or would it be better to invest the extra money into a Twin-Path® sling?

To help you better understand the cost of a Twin-Path sling, and if it’s worth the investment, our article will break down:

- What are the Advantages of a Twin-Path?

- Are There More Affordable Alternatives to a Twin-Path Sling?

What Is the Twin-Path® Sling?

Slingmax’s most popular design and flagship model, the Twin-Path® is a high-performance roundsling made from two individual paths of internal load-bearing fibers – providing extra redundancy if damage occurs to one of the paths during a lift.

It’s made from K-Spec® core yarn, a patented and blended load bearing core fiber that gives the sling extra strength. Its unique design makes the Twin-Path® comparable steel lifting slings while being a fraction of the weight.

Twin-Path® slings have an exceptionally high lifting capacity, with a standard capacity of up to 800,000 lbs. (400-ton). They can be used to lift fighter jets, wind turbines, generators, the setting of towers, and so much more.

Why are Twin-Path® Slings so Expensive?

You can expect to pay 20-30% more for a Twin-Path ® sling than you would for synthetic and steel slings. One of the main reasons for the price increase is that the Twin-Path ® uses special patented material that isn’t used in other lifting slings. They include:

K-Spec® Core Yarn

The two paths that form the Twin-Paths design are made from K-Spec® core yarn, a high-performance blended yarn that is five times stronger than equivalent nylon and polyester fibers. The core yarn gives the Twin-Path less than 1% stretch, comparable to a wire rope sling.

Covermax®

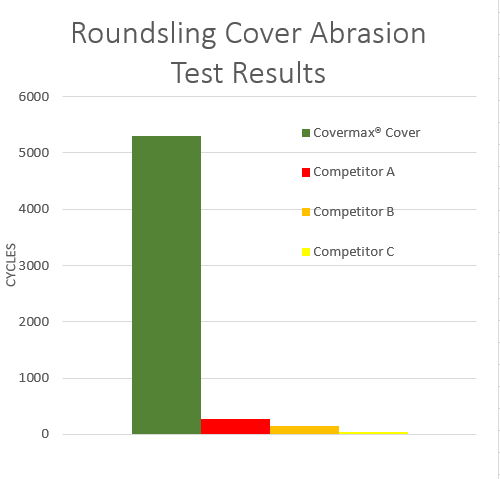

Each sling is made with a bulk nylon covers designed to protect the internal core yarns. The top green layer provides abrasion resistance, and the second layer provides an extra level of protection to the core yarns, but it also is a visual indicator that the top cover has been damaged.

Because of the Covermax® technology, Twin-Paths load-bearing fibers, unlike wire rope or alloy chain slings, aren’t exposed to the load or environmental elements like corrosion, UV damage, and abrasion or cutting damage.

Check-Fast® Inspection System

One of the more unique Twin-Path features is their external warning indicator (EWI) called the Check-Fast® system.

If the sling is overloaded, the indicator is pulled into the sling and disappears before the sling fails. If during inspection, you don’t see the EWI, the sling has been overloaded and needs to be removed from service.

Rifled Cover® Technology

Rifled Cover® Technology is a patented technology which allows for an increased strength-to-weight ratio. It helically twists the core fiber during the fabrication process, increasing the strength of load bearing core fibers by 17%. Rifled Cover® Technology is also used to create the Helix sling, Slingmax’s newest product.

Length and Capacity

The other main factors impacting the cost of a Twin-Path® sling is the length and capacity of the sling you order.

All Twin-Paths are custom made to the customer’s specifications. As with any product, the larger the sling is, the more material and labor is needed, increasing the final price.

For example, a small Twin-Path® only rated for 10,000 lbs. will only cost a few hundred dollars. Meanwhile, Twin-Paths rated for several hundred tons, used in the most extreme overhead lifting applications, could cost tens of thousands of dollars.

For example, a 4′ Twin-Path sling with a 10,000 lbs. vertical capacity will cost around $175. On the other end of the spectrum, a 12′ sling with a rated vertical capacity of 300,000 lbs. will costs over $19,000.

What are the Advantages of a Twin-Path?

Repairable and Backed by Data

Slingmax® has a network of approved distributors who are exclusively licensed, trained, and certified to manufacture, repair and test Slingmax® products—which Mazella is part of.

The benefit of having a sling that can be repaired is you don’t have to constantly buy new slings, saving you money in the long run.

A Great Fit for Multiple Industries

Twin-Paths were designed with high-capacity lifting projects in mind, regardless of the industry. They’re popular in almost any environment where heavy lifting projects are common, including:

- Construction and excavation

- Oil and gas

- Power generation

- Aerospace and military

- Port yards and ship building

- Manufacturing and general industry

Added Durability

The mix of Covermax® and Rifled Cover® Technology gives riggers a sling that can be used in the fields for years. Plus, it would be smart to pair your Twin-Path sling with one of Slingmax’s patented sling protection products. A great option for the Twin-Path would be the CornerMax® Sleeve, a cut-resistant sleeve made from a High Modulus Polyethylene fiber (HMPE).

Ergonomic Design

Twin-Paths are as strong as steel slings while weighing 90% less. This ergonomic design reduces the overall weight of your rigging equipment so your crane can lift closer to its full capacity. It also reduces the need for extra hardware and manual labor on the job site.

This also reduces the number of people required to rig a load compared to heavy chain or wire rope slings, which could require multiple workers or additional equipment, like cranes or forklifts, just to move the slings on or around the job site.

Plus, the lighter design makes it easy for riggers to move around a facility and avoid back, muscle, or tissue damage that occurs when carrying heavy alloy or steel slings.

Are Twin-Paths Cost Effective?

While some may be intimidated by the initial cost of a Twin-Path, you should consider the total value of the rigging over time. When you buy a cheaper lifting sling, it’s more likely to tear and wear out quicker, and is probably not repairable

Twin-Paths slings, when used correctly, can be used in the field for years. According to representatives from Slingmax, they’ve received Twin-Path slings over 10 years old coming in for repairs. Over the lifetime of the sling, it’s going to be less expensive than constantly having to buy cheaper rigging equipment over several months or years.

Are There More Affordable Alternatives to a Twin-Path® Sling?

There are still high-quality Slingmax products to choose from if you can’t afford the Twin-Path sling.

The best option for those on a budget is the Single-Path sling, which has the same features a Twin-Path sling has, including:

- K-Spec® Core Fiber

- Check-Fast® Overload Indicator

- Covermax®® Jacket Material

Single-Path slings require less material and time to manufacture. However, their overall lifting capacity is only 200,000 lbs., a fraction of the Twin-Paths’ 800,000 lbs. lifting capacity. Single-Path slings also do not offer the extra redundancy in case of damage that a Twin-Path offers.

Furthermore, if you’re lifting a load with a smaller diameter, you would want to use the Helix sling.

Are Twin-Path® Slings Worth the Investment?

When performing critical lifts, the cost of rigging equipment is minor compared to the additional safety and peace of mind provided by a Slingmax Twin-Path sling.

While they are significantly more expensive than chains or wire rope, Twin-Paths offer rigging professionals exclusive features and benefits that are impossible to find with standard lifting slings.

High-quality material offers riggers end-user repairability, lower freight costs, and easy storage. Plus, the reduced weight helps prevent shoulder and back injuries. When purchasing a Twin-Path sling, you are also purchasing peace of mind regarding the safety of your load and workers.

But Twin-Paths are not ideal for all environments. They aren’t suitable for high heat environments (above 180°F) and are too wide for some lift points. In these cases, respectively, you will want to opt for a Sparkeater sling and the new Helix sling. Check out our article and video that covers which Slingmax sling is right for you.

Mazzella is one of the largest accredited Slingmax distributors in the country, so contact your local Mazzella representative if you want to purchase a Twin-Path or have further questions.

Copyright 2025. Mazzella Companies.