What Sling Protection is Right for You?

Do you find yourself constantly replacing synthetic lifting slings? In this article, we explore several types of sling protection products that can extend the life of your slings, including the CornerMax Sleeve.

Are you constantly ordering new lifting slings because your previous ones were damaged? Well, you are not alone. Across the lifting and rigging industry, it’s common to view your lifting slings—primarily synthetic lifting slings— as disposable items.

Every sling on a job site should be considered a special tool needing special protection. Not doing so increases your operations cost and puts your workers at risk.

With more awareness on workplace safety (including increased OSHA fines), safeguarding your lifting slings is now a necessity—not a recommendation. But with so many options out on the market, it can be confusing as to what solution you should invest in.

Those researching sling protection are looking for three main outcomes: improve worker safety, protect their loads from damage, and increase the life of their lifting slings.

When considering potential solutions, you should pick one that increases safety and is cost-effective.

For over 70 years, Mazzella has put state-of-the-art solutions in the hands of lifting and rigging professionals. And to help answer potential questions you may have during your decision-making process, we wrote this article to discuss topics like:

- What’s the difference between cut protection and abrasion protection?

- What types of cut protection are available?

- When and where do you need cut protection?

- What is the CornerMax® Sleeve?

- What are the best lifting applications for a CornerMax® Sleeve?

- Is a CornerMax® Sleeve right for you?

What Types of Sling Protection Products are Available?

While there are many types of lifting slings, there are even more options for sling protection, including:

Corner Pads

Corner pads, specifically SlingMax®’s CornerMax® Pads, create a “tunnel” of cut protection where the sling doesn’t contact the load’s edge.

Wear Pads

Commonly used with wire rope and chain slings, wear pads act as a buffer between the load and the sling.

Corner Protectors

Lightweight and easy to use, magnetic corner protectors are placed directly onto the corners and edges of steel loads, instead of placing them on the lifting sling.

Additionally, they can be used on synthetic, wire rope, and synthetic rope liftings slings, and they have a maximum loading capacity of 12,500 PSI.

Covers and Sleeves

Covers and sleeves are ideal for protecting synthetic slings when it’s not practical to use a corner pad.

Reinforced Eyes

An endless sling with butted edges sewn together to double the sling width.

What’s the Difference Between Abrasion and Cut Protection?

During your research, you will come across two types of protection:

Abrasion protection is ideal for lifting any rounded, rough edges. For example, when lifting a large stone or concrete slab, an abrasion protection sleeve will keep it safe from a rough edge, preventing additional damage to your sleeve.

Cut protection is best when lifting loads at a 90-degree angle. No matter how dull the angle may appear, it can still cut into a sleeve with enough applied pressure. You would want to use cut protection for lifting steel beams and loading and unloading steel coils.

When Would You Use Synthetic Sling Protection?

On a job site, every lift should be seen as critical, meaning every lift performed should have protection. Whether you’re using synthetics, wire ropes, wire mesh, or alloy chains, any lifting sling on a job site should have protection.

While many see synthetic slings as easily disposable items, they’re still an integral part of every lift.

What Is the CornerMax® Sleeve and What are Its Benefits?

Developed by SlingMax Rigging Solutions, the CornerMax® Sleeve is a lab-tested, extremely cut-resistant sleeve designed for protecting synthetic lifting slings.

Unlike lifting pads, which are ideal for loads with 90-degree straight edges, the sleeve can form around most geometric shapes. Whether it’s a steel coil, an I-beam, or a stone slab, the CornerMax® Sleeve’s flexible shape makes it a versatile tool at your job site.

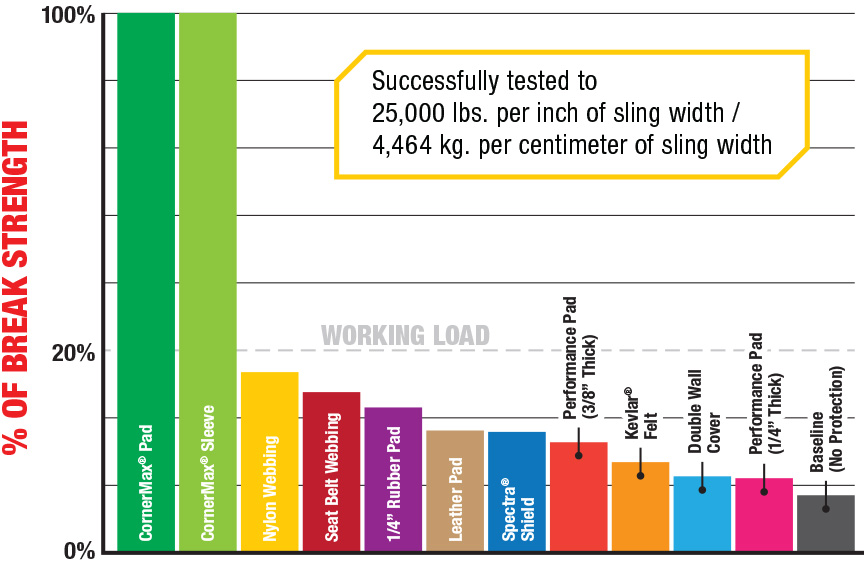

Because it’s made from a High Modulus Polyethylene fiber (HMPE) and features a tight weave, the CornerMax® Sleeve can reach 25,000 pounds per square inch of sling width, exceptional by industry standards.

What are the Biggest Benefits of Using a CornerMax® Sleeve?

Historically, synthetic web slings were viewed as disposable items. While popular for being ergonomic and affordable, their material makes them susceptible to damage in certain applications, especially those involving sharp edges.

With a CornerMax® Sleeve, synthetic lifting slings can now be used in applications dominated by wire rope slings, alloy chains, and mesh.

Not only will you save money by not having to purchase wire ropes and alloy chain slings, but the CornerMax® Sleeve also extends the lifespan of your current slings—eliminating the need to constantly replace damaged ones.

Can a CornerMax Sleeve Only Be Used with Slingmax® Products?

One of the biggest benefits of a CornerMax® Sleeve is its versatility. While it’s made by Slingmax®, the CornerMax® Sleeve is not exclusive to their slings.

In addition to Slingmax®’s high–performance Twin-Path® and Single-Path slings, our safety experts encourage anyone needing cut protection to use CornerMax® Sleeve on their flat web slings, polyester roundslings, or any synthetic lifting sling on your job site.

Can You Use CornerMax® Sleeves on Alloy Chains or Wire Rope Slings?

Because of the CornerMax Sleeve’s specific design, our experts recommend not using it with any wire rope or chain lifting slings. Since the sleeve is specifically designed for synthetic material, wire rope or chain lifting slings would put immense pressure on the sleeve, crushing and / or tearing it.

Additionally, you would not get that guaranteed protection of 25,000 pounds per usable inch of sling width.

What Inspection Criteria Comes with a CornerMax® Sleeve?

With the CornerMax Sleeve, you would inspect it just like any other lifting sling. Go through and see if there are any tears, holes, punctures, or fraying at the edges.

If any of these are found, immediately remove the sleeve from the job site.

What are the Best Practices for Using a CornerMax® Sleeve?

Before lifting a load, ensure the CornerMax Sleeve is fully connected to the entire surface. You will want to avoid placing just the edge of the sleeve on the surface, as you won’t achieve complete protection.

Is a CornerMax® Sleeve Right for You?

Making your lifting operations safer and more cost-effective doesn’t have to be an ultimatum. With state-of-the-art solutions like the CornerMax® Sleeve, both your equipment and workers are put in a safer position.

With decades of first-hand experience in safeguarding lifting projects, Mazzella has plenty of useful, informative content to help you in your decision-making process. Want to learn more about lifting slings and their ideal applications? Download our extensive Lifting Slings Types & Terms E-Book.

Need a good podcast to listen to? Check out our Safety Factor podcast series that dives into a variety of industry-related safety topics.

Copyright 2024. Mazzella Companies.