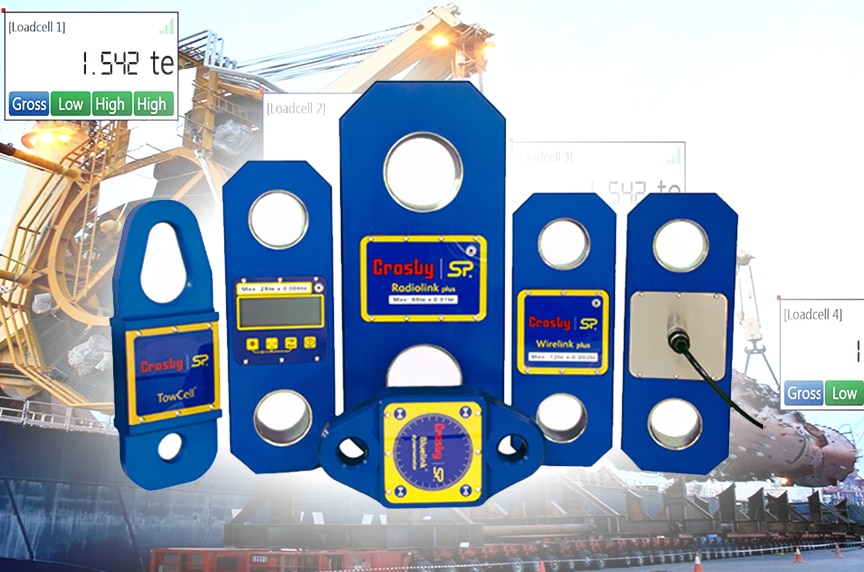

Which Crosby | Straightpoint Load Cell Is Right For You?

You know you need a load cell to help accurately measure the weights of your lifts, but which one is right for you? Crosby | Straightpoint has a diverse line of products that can help meet your needs when making overhead lifts.

If you care about the safety of your workers, there is no room for guessing when determining the weight of a load.

Rather than guessing how much a load weighs as you’re doing your lift planning, there is a way to accurately monitor what your cranes are lifting.

Crosby | Straightpoint load cells are focused on taking the guesswork out of lifting. They want you to know your load’s exact weight and eliminate the risks associated with not using a load cell/dynamometer.

If you don’t eliminate hazards as often as possible when lifting loads, it could lead to catastrophic failure. In a worst-case scenario, a failed lift could damage the load, or more importantly, cause injury or death.

In this article, we’ll look at the following:

- What is a Crosby | Straightpoint Load Cell?

- What is the Radiolink Plus?

- What is the BlueLink?

- Which type of load cell is best for you?

What Is a Crosby | Straightpoint Load Cell?

Using a load cell or dynamometer is all about knowing how much you’re going to pick up.

The load cell is an indication device that will show you how much weight you have on your hook. Strain gauge technology measures the microscopic strain on the body of the load cell. Then, the results are converted into a pound, kilogram, kilonewton, or metric ton reading.

What Is the Radiolink Plus?

This is Crosby | Straightpoint’s link-style load cell with shackles on the top and bottom. It is their most commonly used load cell for monitoring loads. In their opinion, monitoring load weight should be done for every lift.

You put one shackle on the hook and attach the rigging to the bottom shackle. A wireless handheld device receives the information, which helps keep operators a safe distance away from the lift.

The wireless handheld device has a 1,000-meter range, which equates to 3,280’. Although Crosby | Straightpoint rarely sees applications with a need to be that far away from the load, it means the Radio Frequency (RF) signal from The Radiolink Plus is reliable and will remain strong at these varying distances.

Reading the Results

Some load cells you may see in the industry have an integral screen or on-board display. This may be appealing in certain situations. However, it also creates some challenges, for instance:

- The operator must remain in close proximity to the load

- It is difficult to read the data from far away

- The integral screen is much more susceptible to damage

Because of space limitations, the screen is typically an inch or less in size. In some cases, it’s not backlit, making it even harder to read. You’ve either got to be really close to the load, which puts you at more risk for serious injury/death, or utilize a lower-tech option like binoculars.

Binoculars still may not be enough, as it could be difficult to tell apart similar-looking numbers on the screen. Results obtained this way may not be able to answer if the crane/rigging gear being used to complete the task is suitable to perform safe lifts.

The Radiolink Plus load cell is strictly wireless. There is no screen / read-out built into the structure of the cell. The Radiolink Plus is manufactured from high-quality aerospace aluminum and can remain functional if gouged or dinged because it also features a completely polycarbonate front plate.

If your load cell’s screen is damaged, it can no longer be used without first going in for assessment / repair.

What Are the Key Specifications of the Radiolink Plus?

Range

The wireless radio frequency signal can reach up to 1,000 m or 3,280’.

Weight

Depending on which of the 14 models of the Radiolink Plus you select, it can weigh as low as 3.3 lbs. (1.5 kg), or as large as 425 lbs. (193 kg).

Capacity

The smallest Radiolink Plus has a capacity of 2,200 lbs. (1,000 kg), and the largest model has a capacity of 1.1 million lbs. (500 metric tons).

Battery Type / Life

The Handheld Display requires 2 AA batteries, while the load cell needs 4 AA batteries.

Display Type

The Radiolink Plus comes with a separate handheld display featuring 240×128 multi-line dot matrix with backlight. Also, the handheld display is capable of reading up to four Crosby | Straightpoint load cells at one time.

Operating Temperature

The Radiolink Plus can operate between 14° to 122°F (-10° to +50°C).

Accuracy

Across all 14 models, the Radiolink Plus has an accuracy of +/- 0.1% full scale.

Frequency

The Radiolink Plus has a 2.4 GHz frequency.

Protection

The Radiolink Plus is IP67 rated. It is dust tight and watertight against water immersion between 15 cm and 1 m for 30 minutes.

What Is the BlueLink Bluetooth Dynamometer?

Crosby | Straightpoint has customers who have said, ‘Hey, I’m working on an auto crane on the side of a truck. It’s 1-ton. I don’t need to be 200’ away. I just need something that’s going be reliable, and lightweight, where I can put it in use and see the results on my phone using an app.”

Enter the BlueLink Bluetooth Dynamometer.

The BlueLink Bluetooth Dynamometer has a 6½-ton capacity. It’s a Bluetooth-only device meant to be used with Crosby | Straightpoint’s HHP app, which is free on Android and iOS platforms, and the customer can monitor the loads on their phones.

Also, the app has a record and log feature for when you need to record a particular measurement for later referral. Once logged into the app, it will allow you the convenience of exporting the details of the logged measurement(s) either to your mobile device, or send it to a particular email address in a spreadsheet format.

Monitoring the Results

Crosby | Straightpoint designed the BlueLink Bluetooth Dynamometer to connect to up to eight devices simultaneously.

Let’s say you want to monitor the load while the crane operator is executing a lift. The operator doesn’t have to pass off the phone or wireless handheld device because the app allows you to monitor the load.

As a double-check, if there’s a project engineer who wants to monitor the lift as well, all three can check the progress of the lift through the app without having to share and risk losing wireless display devices.

The app allows for teamwork and project specialization with one person executing the lift and focusing on the load. That person is watching the crane, watching the operation of the lift and controlling it.

By having a second person monitor the load cell, they will give an audio cue to the operator to keep executing the lift or to stop because the crane is overloaded.

For a solo working environment, The HHP app has an audible alarm that’s programmable, so the operator really knows when the load is nearing the crane’s capacity to help avoid overload events.

What Are the Key Specifications of the BlueLink Dynamometer?

Range

The wireless range signal can reach up to 100 m or 328’, which is 1/10th of the frequency of the Radiolink Plus.

Weight

The BlueLink Dynamometer weighs 3.3 lbs. (1.5 kg).

Capacity

The BlueLink Dynamometer comes in one model, and its capacity is 14,300 lbs. (6.5 metric tons).

Battery Type / Life

The BlueLink requires 4 AA batteries, and they can operate the unit for up to 500 hours.

Display Type

Because it is a Bluetooth device, the BlueLink sends results to your smartphone and can view up to four Crosby | Straightpoint load cells at one time

Operating Temperature

The BlueLink Dynamometer can operate between 14° to 122°F (-10° to +50°C).

Accuracy

This dynamometer has an accuracy of +/- 0.2% of full scale.

Protection

The BlueLink is IP67 rated. It is dust tight and watertight against water immersion between 15 cm and 1 m for 30 minutes.

What Are the Differences Between the Radiolink Plus and BlueLink?

The biggest differences between the Radiolink Plus and BlueLink are:

- Range

- Accuracy

- Capacity

Range

A link-style load cell, the Radiolink Plus’s wireless signal range of the Radiolink Plus is up to 1,000 m or 3,280’, which is 10 times the frequency strength of the BlueLink (100 m, 328’).

Accuracy

The Radiolink Plus has an accuracy of +/- 0.1% full scale, while the BlueLink has an accuracy of +/- 0.2% full scale.

Capacity

Because there are 14 models of the Radiolink Plus, they can have a capacity of anywhere between 2,200 lbs. (1,000 kg), and the largest model has a capacity of 1.1 million lbs. (500 metric tons). The BlueLink Dynamometer comes in one model, and its capacity is 14,300 lbs. (6.5 metric tons).

Which Crosby | StraightPoint Load Cell Is Best for You?

Crosby | Straightpoint really worked hard to make these tools user-friendly. That means being able to open the case, turn on the device simply by hitting the power button and

Limitations

Crosby | Straightpoint’s load cells are designed to operate between 14°F (-10°C) and 122°F (50°C). If you’re making a lift in sub-zero temperatures, it’s probably not a fit for Crosby | Straightpoint’s load cells.

Conversely, in hot forge foundries, customers will put a load cell on a crane that’s getting up to 150°F, and others have said, “It’ll flash a temperature of 250°F.” Crosby | Straightpoint doesn’t have an effective solution for something that hot.

Crosby | Straightpoint does make custom project load-monitoring solutions, so special applications can be reviewed for capabilities.

If you work in a hazardous environment where you’re using spark-resistant cranes and hoists and explosion-proof equipment, Crosby | Straightpoint has an ATEX (Atmosphere Explosible)-rated load cell that can be used in those hazardous environments. The specialized load cell must be marked by ATEX and has to be ATEX-approved.

***Remember to have conversations with your rigging specialists and reach out to manufacturers to understand what you’re getting into because the equipment / tools business is not a “one-size-fits-all, out-of-the-box” application. Do your research on what you’re about to rig BEFORE you rig it.

Summary

If you need a longer range from the crane to your display, more accurate rating or higher capacities, the Radiolink Plus will be your better option.

How Can Mazzella Help with Your Lifting and Rigging Needs?

For decades, Crosby has manufactured products to make the lifting and rigging industry safer. Similarly, Mazzella has the mission to provide you with quality products that are the right fits to increase your productivity and minimize your safety risks.

Mazzella is a distributor of Crosby products of all types, including, but not limited to:

- Radiolink Plus

- BlueLink

- Wireless Load Shackle

- BlokCam

- Verton

- Crosby Gunnebo GrabiQ Chain Slings

- Clamps

- Pipe Grabs

- Sheaves

- Bearings

- Blocks

- Sling Saver Hardware

- Turnbuckles

- Hooks

- Thimbles

By using the proper equipment, you’re controlling or eliminating hazards in the workplace. That helps reduce the risk of an accident. Think about how quickly the costs of a workplace accident or fatality can add up, including:

- Lost wages

- Workers’ compensation

- Low employee morale

- Decrease in productivity

- Workforce shortages

- Potential legal fees and OSHA fines

Remember, putting safety at the forefront of your lifts will help increase your productivity and minimize your downtime.

Click here to contact a Mazzella lifting specialist today for all of your lifting needs!

Crosby|Straightpoint Load Cell Dynamometers

Crosby designed the Radiolink Plus to be rigged with Crosby standard shackles. Straightpoint’s DNV-GL type approved wireless tension load cell is capable of weighing and dynamic load monitoring capacities from 1t to 500t (all in stock).

Copyright 2023. Mazzella Companies.