What Is Harrington’s LB Heavy Duty Lever Hoist?

Why should you consider purchasing a Harrington LB Heavy Duty Lever Hoist from Harrington? Simply put, after more than 150 years in business, Harrington understands the needs of the end-user and engineers quality machines that help improve productivity and safety.

“Almost all quality improvement comes via simplification of design, manufacturing…layout, processes, and procedures.” –American businessman Tom Peters.

Learning from feedback provided by end-users, Harrington Hoists, Inc. made several improvements to its LB lever hoist.

If you’re looking for a versatile hoist with an improved design, the Harrington LB Heavy Duty Lever Hoist may be the answer you’ve been looking for all along.

For more than 150 years, Harrington Hoists, Inc. has been providing you with solutions for your lifting and rigging needs.

In this article, we’ll answer the following questions about the Harrington LB Heavy Duty Lever Hoist:

- What is the Harrington LB Heavy Duty Lever Hoist?

- Which unique features does the Harrington LB Heavy Duty Lever Hoist offer?

- What are the maintenance and service classes for the Harrington LB Heavy Duty Lever Hoist?

- How do you get replacement parts for the Harrington LB Heavy Duty Lever Hoist?

What Is the Harrington LB Heavy Duty Lever Hoist?

After studying several industries where lever hoists were used, the LB Heavy Duty Lever Hoist was completely redesigned. Now, it gives operators all of the needed features in one hoist, be it for day-to-day maintenance and service work to heavy-duty construction applications.

With the improved design, the LB hoist features the following advantages over other hoists:

- Compact size

- Lighter weight

- Can work in low-headroom applications

- Ease of:

- Operation

- Transportation

- Storage

- Trouble-free maintenance

The LB hoist has a heavy-duty all-steel construction with a Weston-style mechanical load brake. Also, it features a nickel-plated corrosion-resistant load chain, and is available in the following capacities:

- ¾ ton

- 1 ton

- 1½ tons

- 2 tons

- 2¾ tons*

- 3 tons

- 6 tons

- 9 tons

*The 2¾-ton model is the industry’s first of its kind.

Currently, the LB Heavy Duty Lever Hoist is being used in the following applications:

- Maintenance

- Repairs

- Construction

- Mining

- Manufacturing

- Shipbuilding

What Are the Unique Features of the Harrington LB Heavy Duty Lever Hoist?

This heavy-duty hoist can be used horizontally, vertically, inverted or any other load angle, and has proven tough enough to stand up to any environment. It offers you several unique features and benefits, including:

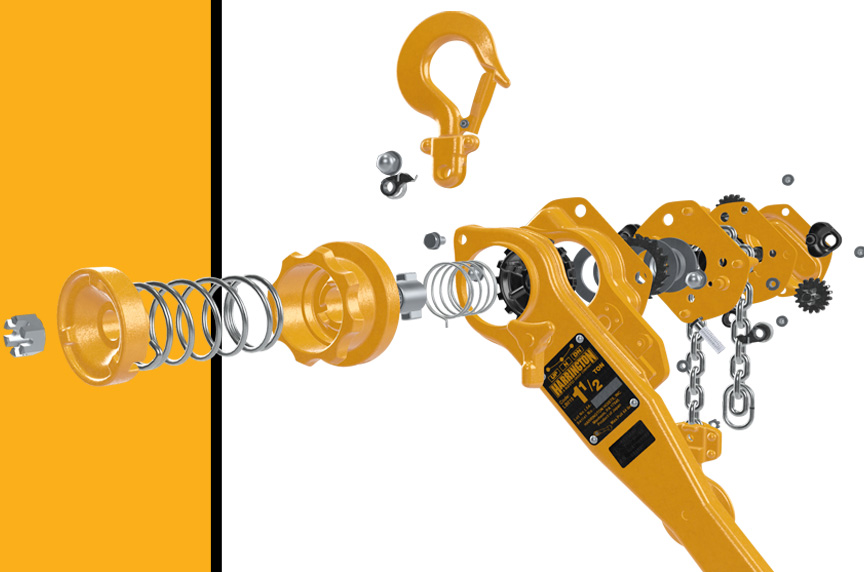

Patented Hardening Process

Forged with an advanced high-frequency heat-treating process ensures uniform hardness of all key load-bearing parts. The process creates a truly rugged hoist you can feel comfortable taking into multiple environments.

Failsafe Freewheel System

The patented spring-loaded freewheel mechanism allows for easy adjustment of the load chain. Additionally, it safeguards against accidental freewheeling under load.

Safety Tip Hook and Latch

Having to take a hoist out of service due to a damaged or broken hook latch is costly in terms of downtime. The LB latch was designed to protect it from damage. The notch at the end of the latch was designed to engaged the tip of the hook. This helps protect it from lateral impact damage.

Additionally, the latch is made of heavy gauge steel and secured by a wide anchor at the base to increase rigidity.

State-of-the-Art Chain Technology

For decades, Harrington has been known for manufacturing and using a lighter-weight, ultra-strong, high-performance load chain in its hoists. The Grade 100 chain uses a shorter and narrower link profile, which ensures greater surface area contact. This helps improve wear resistance and tensile strength.

Structural Steel Side Plates

Regionalized heat-treated side plates provide extreme rigidity to avoid body deformation. Also, they allow for increased operational efficiency, no matter what is being lifted. This heat-treatment process helps prevent abrasion to the load chain during contact with the side plates.

What Are the Design Elements of the Harrington LB Heavy Duty Lever Hoist?

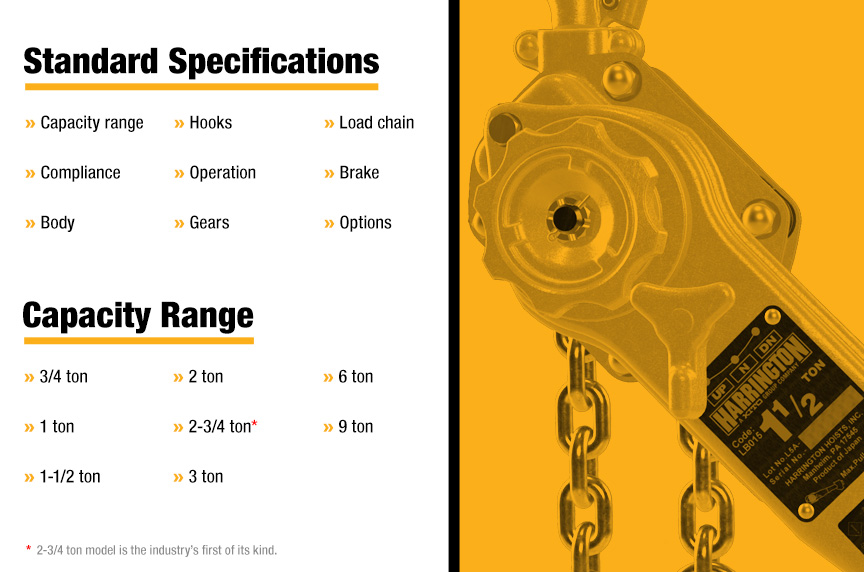

In the manual for the Harrington LB Heavy Duty Lever Hoist, Harrington outlines the following specifications for each of these products, including:

- Capacity range

- Compliance

- Body

- Hooks

- Operation

- Gears

- Load chain

- Brake

- Options

Capacity Range

There are eight different capacities for the Harrington LB Heavy Duty Lever Hoist. They cover the following weight ranges:

- ¾ ton

- 1 ton

- 1½ tons

- 2 tons

- 2¾ tons

- 3 tons

- 6 tons

- 9 tons

Compliance

The LB lever hoist was built to the ASME B30.21 Lever Hoists standard. Additionally, it adheres to the ANSI / ASME HST – 3M Performance Standard for Lever Hoists.

Body

The rugged, high-impact, all-steel construction weighs less than comparable aluminum models Here are the following weights of each hoist with 5’ of chain:

- ¾ ton-13 lbs.

- 1 ton-13 lbs.

- 1½ tons-18 lbs.

- 2 tons-25 lbs.

- 2¾ tons-25 lbs.

- 3 tons-33 lbs.

- 6 tons-57 lbs.

- 9 tons-88 lbs.

Also, it has an open design, which allows for easy inspection and cleaning without dismantling the unit.

Hooks

The hooks are made of forged, heat-treated alloy steel. They open gradually without fracturing under excessive load.

The top and bottom hooks have:

- Heavy-duty hook latches

- The ability to rotate 360°

Operation

The rubber grip handle allows for non-slip operation. It can operate in close quarters with a short handle and 15° recovery stroke.

Also, the patented spring-loaded freewheel mechanism for easy adjustment of the load chain. It protects against accidental freewheeling under load.

Gears

The LB Heavy Duty Lever Hoist features highly durable, split-load double reduction gears. These gears were induction heat-treated and case-hardened, and are enclosed to protect from dust and moisture.

Load Chain

The Grade 100 heat-treated load chain is nickel-plated for corrosion resistance. It has standard lifts of 5’, 10’, 15’, or 20, and custom lengths are available.

Brakes

The Weston-style load brake has four braking surfaces, two brake pads and two brake pawls for added security. The brake mechanism is completely enclosed to protect from dirt and moisture.

Options

Slip Clutch

This feature helps prevent the hoist from being used to lift damaging loads beyond rated capacity.

Top Hook Extender

The extender allows you to locate the hoist body away from its attachment point.

Load Limit Warning Handle

This handle alerts the operator when the hoist is being used to lift damaging loads beyond rated capacity.

Shipyard / Point Hooks

These hooks allow for point loading, which is a concentrated lift where only a very small area or specific point is being lifted.

Bullard® and SmartLok™ Hooks

These hooks allow for a locking latch feature.

Inspection Hooks

The inspection hooks allow for inspection of the internal parts of the hook set.

Custom Lift Lengths

These lengths help suit any requirements you have for your hoists.

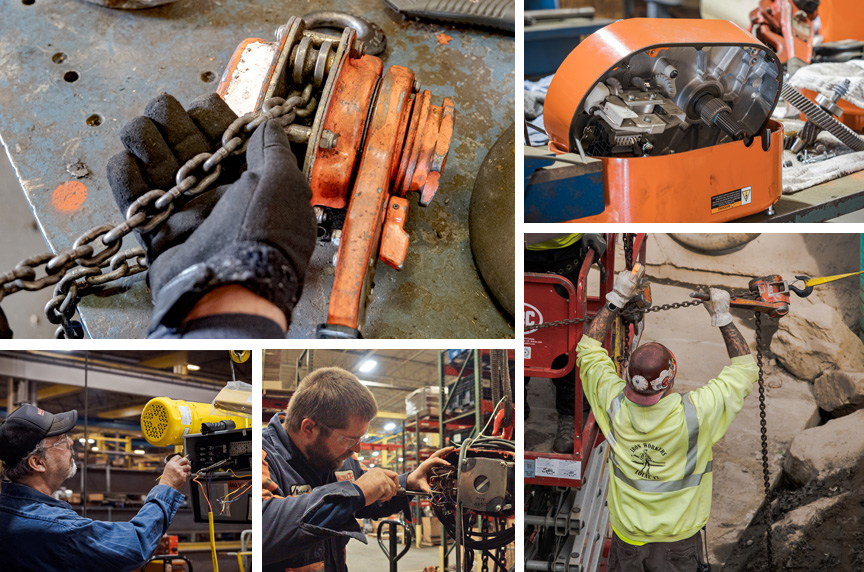

What Are the Maintenance and Service Classes for the Harrington LB Heavy Duty Lever Hoist?

Every box shipped containing a Harrington product will include an owner’s manual. The owner’s manual will tell you how to determine the maintenance schedule for each of their products, along with other important information.

As the owner of the hoist, you have to figure out which of the following classifications applies to your applications:

- Normal Service

- Heavy Service

- Severe Service

Normal service is defined as operations with randomly distributed loads within the rated load limit or uniform loads less than 65% of the rated load limit for more than 25% of the time.

Heavy service is defined as operations within a working load limit which exceeds normal service. That is classified as hoists whose lifts exceed 65% of the rated load for more than 25% of the time or randomly distributed loads for over 25% of the time.

Severe service involves normal service and heavy service under abnormal operating conditions like weather or constant running.

Inspection Requirements

Once you determine what service classifications your hoists fall into, there are two types of inspections:

- Frequent inspection

- Periodic inspection

Designated persons or operators perform the frequent inspections at the facility:

- For normal service, frequent inspections would be needed monthly

- Under heavy service, weekly to monthly

- For severe service, daily to weekly

Designated persons perform periodic inspections. Harrington partners with Mazzella to provide these services. These inspections occur:

- At least yearly for normal service

- Semiannually, at least, for heavy service

- Quarterly for severe service

If you need your hoists repaired, you can contact Mazzella, which is a Harrington repair center, or speak with Harrington directly if you’re not sure who does repairs in your area.

By tracking the serial number of the product, Harrington can determine who you purchased the hoist from and guide you to that distributor first. If that company doesn’t do repairs, Harrington would put you in contact with a service repair center in your area.

How Do You Find Replacement Parts for the Harrington LB Heavy Duty Lever Hoist?

You cannot purchase replacement parts directly from Harrington, as the company only sells products through distributors.

Mazzella is a master parts distributor for Harrington and carries many products to fulfill your needs.

For any further questions, you can contact your local sales representatives. If you go to Harrington’s website under the “Resources” page, there is a “How To Buy” link. You can type in the first three numbers of your zip code, and the “How To Buy” program will pull up the information for the local territory representative.

How Can Mazzella Help With Your Hoists?

Mazzella is your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

If you are not looking to replace a hoist, we also have a Hoist Repair Department available to get your hoist back up and running. We provide in-house repair of electric, lever, manual chain, and wire rope hoists.

We offer you the following with our hoist service division:

- Experienced and qualified technicians assigned to perform hoist inspections and repairs

- Repairs and testing that comply with ASME B30.16 Overhead Underhung and Stationary Hoists and ASME B30.17 Cranes And Monorails (With Underhung Trolley or Bridge) specifications

- Static and dynamic testing

- Test certificates that are available electronically or a hard copy on paper

- Repairs and testing performed at our facility

- Load testing of all repaired hoists and pullers

- Repairs and tests to theatrical standards upon request

Call us at 800.362.4601 or click here if you need hoist units, parts, or repairs!

Harrington Hoists

Mazzella is your one source for hoisting products with lifting capacities ranging up to 100 tons. We offer many types of electric, air, and manual hoists for limitless applications.

The Harrington Hoists product line includes electric and air powered chain hoists and trolleys, electric wire rope hoists and trolleys, lever hoists, manual hand chain hoists, push and geared trolleys, overhead cranes, crane accessories and a full line of replacement parts. Harrington Hoists, Inc. is ISO 9001 certified.

Copyright 2023. Mazzella Companies.