SE Hoists, PE Hoists, and CE Hoists: Which Should You Choose?

Mazzella offers three types of engineered hoists: the SE standard hoist, the PE pre-engineered hoist, and the CE custom-engineered hoist. This article breaks down the differences between them, and which one is right for you.

Selecting the right type of hoist is crucial for optimizing efficiency, safety, and cost-effectiveness in any operation. But how do you pick the right hoist for your application?

Mazzella offers three distinct types of hoists: the SE standard hoist, the PE pre-engineered hoist, and the CE custom-engineered hoist. Each of these hoists is designed to meet specific needs, applications, and industries, ensuring customers can find the perfect solution for their lifting requirements.

But picking the wrong hoist for a job can cause unplanned downtimes, unsafe working conditions, and lost productivity. Mazzella Companies has long been a leader in the field of hoist engineering, providing innovative lifting solutions to a wide range of industries.

To help you make an informed decision, this article will compare the unique features, advantages, price ranges, and limitations of each hoist type.

What Is the SE Standard Engineered Hoist?

Designed for monorails and cranes, standard engineered hoists are a reliable and cost-effective hoist solution. Featuring a 2-speed or VFD control, and engineered to exceed ASME H4 Duty standards, standard engineered hoists are ideal for light to heavy duty applications, offering a compact design that facilitates easy installation and maintenance.

An SE hoist can be found in a variety of environments, including:

- Manufacturing plants

- Warehouses and storage facilities

- Maintenance facilities

- Light to medium duty industrial applications.

What are the Key Benefits of a SE Standard Engineered Hoist?

Compact Design

Their space-saving design makes SE hoists great choices for smaller facilities. The compact design also makes it easy for installation and maintenance, reducing downtime.

Reliable Performance

SE hoists are built to exceed ASME H4 Duty standards, ensuring dependable operation. These hoists are available with options such as overcapacity protection to improve safety.

Cost-Effective

If you are not doing complex lifts, and don’t have access to a large budget, SE hoists offer a reliable solution at a lower cost compared to more specialized hoists. The typical price range for a standard engineered hoist is from $15,000 to $50,000.

What are the Downsides of an SE Hoist?

Limited Customization

The SE hoist comes with pre-designed specifications and limited options for customization, which may not meet the needs of highly specialized applications.

Capacity Limitations

The capacity for most standard hoists goes only up to 15 tons, making it unsuitable for heavier lifting requirements.

Standard Features

While it includes essential safety and operational features, it lacks the advanced options and flexibility found in pre-engineered and custom-engineered hoists.

What are Pre-Engineered Hoists?

The PE pre-engineered hoist is designed for heavy manufacturing, steel service, aerospace, defense, foundries, and paper mills. It is built to handle heavy to severe duty applications, offering a robust and versatile solution that meets CMAA Class D&E service requirements.

The PE pre-engineered hoist is ideal for:

- Heavy Manufacturing

- Steel Service Centers

- Aerospace

- Defense

- Foundries and Paper Mills

What are the Key Features of Pre-Engineered Hoists?

- High-Efficiency Gears: Helical, splash-lubricated gears for smooth operation.

- Durable Wheels: Dual-flanged steel wheels with treads and flanges hardened to minimum 425 BHN.

- Motors: Continuous duty, cast iron frame motors with Class H insulation.

- Drum and Reeving: Minimum 20:1 drum to wire rope ratio for true vertical lift.

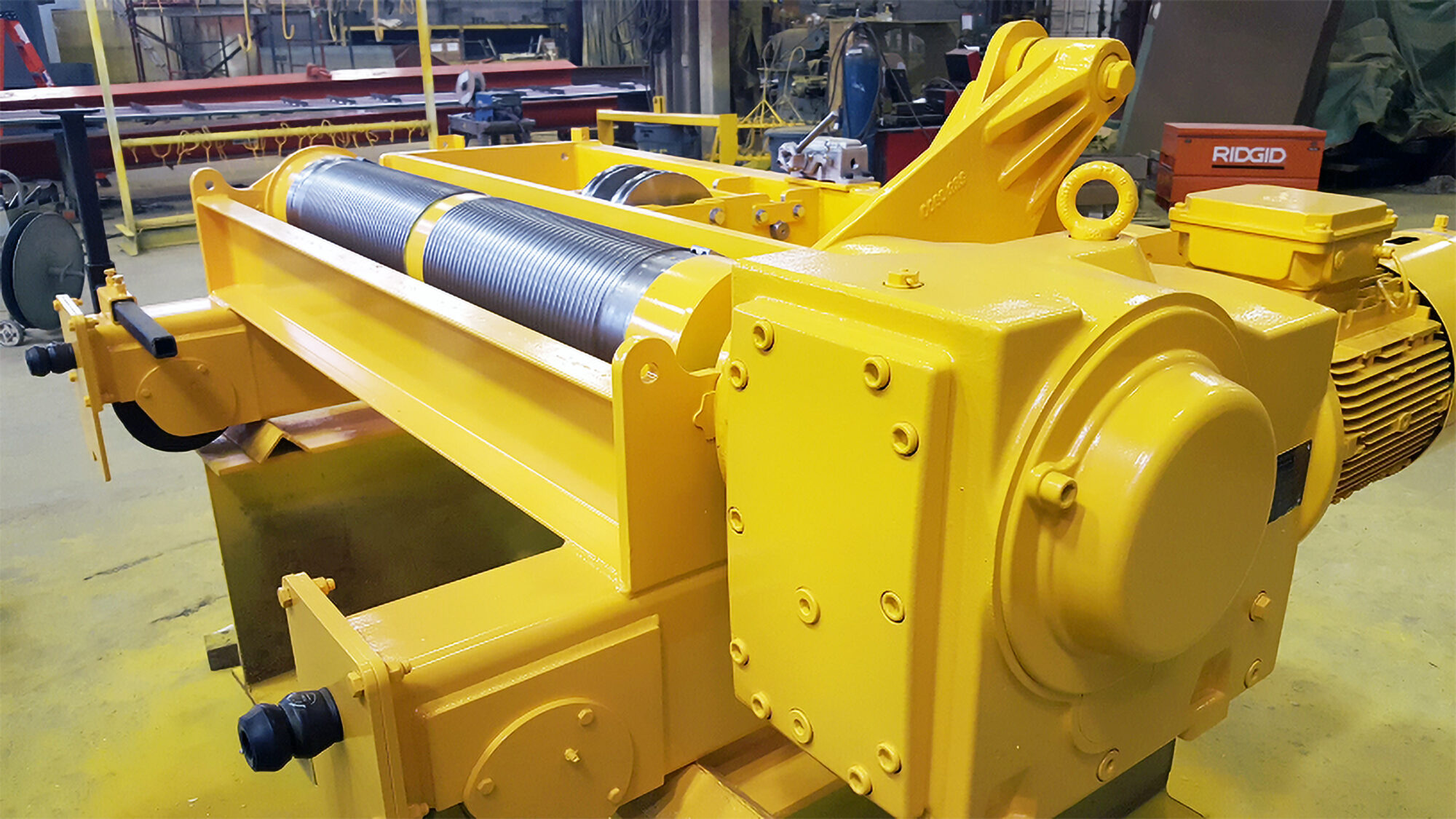

- Open Winch Design: Welded structural steel frame for added strength.

- Controls: Flux vector VFD hoisting, VFD trolley, 460/3/60.

What’s the Price Range for a PE Hoist?

The PE pre-engineered hoist is priced between $50,000 and $150,000, depending on the capacity and specific requirements. This makes it a more expensive option compared to standard hoists but offers greater versatility and robustness.

What are the Advantages of a Pre-Engineered Hoist?

Versatile Design

PE hoists are available in a wide range of lifts and speeds with options for moderate customization.

Robust Construction

PE hoists are built to handle heavy to severe loads with high efficiency. They are designed for reliable operation and easy access to components for ease of maintenance. These hoists are built for long service life when applied in the correct application and maintained properly.

Commercially Available Components

PE hoists are built using commercially available components. Drawings are also provided for all machined components, allowing for local sourcing.

Customization Options

Offers more options for faster speeds, longer lifts, and additional features compared to standard hoists. Additional safety features are available as well as other features such as motorized bottom blocks.

What are the Downsides of a PE Hoist?

Higher Initial Cost

Pre-engineered hoists are significantly more expensive than standard hoists, which may be a consideration for budget-conscious projects.

Frequent Maintenance Requirements

The more complex components and heavy-duty usage may require more frequent maintenance.

Limited to 40 Tons

While it offers greater capacity than standard hoists, it is still limited to 40 tons, which may not be sufficient for some applications. In those applications where loads exceed 40 tons, a CE custom engineered hoist would be a better option.

What are CE Custom-Engineered Hoists?

The CE custom-engineered hoist is designed to meet the most demanding applications, offering a highly customizable solution for extreme environments and heavy-duty usage. It is ideal for industries that require continuous operation at near full capacity, such as the steel industry and shipyards.

What are the Key Features of Custom-Engineered Hoists?

- High-Quality Gearbox: Foot-mounted hoist gearbox with high-quality gearing, ground and hardened to AGMA 12 standards.

- Durable Brake System: Foot-mounted AC thruster shoe brake for reliable stopping power.

- Robust Drum Construction: Welded steel construction hoist drum with 1/2 depth grooving to minimize wire rope wear.

- Advanced Wheels: Rotating axle wheels supported on spherical roller bearings for smooth operation.

- Custom Controls: Variable frequency (VFD) control packages with full automation features, including HMI displays and data loggers.

- Safety Features: Includes overload protection, centralized lubrication systems, and advanced limit switches.

Why Do Custom-Engineered Hoists Cost So Much?

The CE custom-engineered hoist is priced between $75,000 and $400,000, depending on the capacity and specific customization requirements. The advanced features and high customization offerings make them the most expensive option among the three hoist types. They also have the largest price range of the three.

Which Industries Should Use Custom-Engineered Hoists?

Custom-engineered hoists are meant to handle the most demanding applications in the most demanding industries. These hoists can be used in:

Steel Industry

CE hoists are great for heavy to continuous duty applications requiring heavy lifting and precise control. These hoists can be customized to any steel project specification, ensuring full compliance to all requirements.

Shipyards

They are commonly used for lifting and moving large ship components and materials.

Heavy Manufacturing

For demanding applications that require robust and reliable lifting solutions.

Aerospace

For specialized lifting requirements in aerospace manufacturing and maintenance.

Defense and Military Manufacturing

For heavy to severe duty lifting including critical lifts that require additional redundant safety features as well as for hazardous environments.

What are the Advantages of a Custom-Engineered Hoist?

Highly Customizable

As the name implies, CE hoists can be tailored to meet specific industry requirements, including advanced control systems and specialized components.

High Durability Ratings

CE hoists are built to handle the most demanding applications with high-quality materials and components. CE hoist can run at near capacity, two to three shifts a day, seven days a week.

Advanced Features and Safety Add-Ons

All CE hoists come with state-of-the-art control systems and safety features for optimal performance and reliability.

Commercially Available Components

Like pre-engineered hoists, custom-engineered hoists are built using commercially available components. Drawings are also provided for all machined components, allowing for local sourcing.

What are the Downsides of a Custom-Engineered Hoist?

Higher Cost

The high level of customization and advanced features give the CE hoists a higher price tag, making it the most expensive option.

Specialized Maintenance

Because of their unique designs, CE hoists may require specialized maintenance and parts, which can add to the overall cost of ownership.

Complex Installation

The advanced features and customization options may require more complex installation and setup compared to standard and pre-engineered hoists.

Which Engineered Hoist Should You Choose?

While all three hoist models are exceptional at improving lifting operations, each comes with their unique features, advantages, and potential downsides. Here is what you should keep in mind:

- The SE standard hoist is a practical choice for many standard lifting applications, offering a balance of performance, reliability, and cost-effectiveness. However, for more demanding or specialized needs, the PE pre-engineered or CE custom-engineered hoists may be necessary.

- The PE pre-engineered hoist is a versatile solution for heavy-duty applications, offering greater capacity and customization options compared to standard hoists. However, it comes with a higher initial cost and may require more maintenance, making it important to consider the specific needs and budget of your project.

- The CE custom-engineered hoist is the ultimate solution for the most demanding lifting applications, offering unparalleled customization and advanced features. While it comes with a higher cost and may require specialized maintenance, its robust construction and state-of-the-art control systems make it the ideal choice for industries that require long-term reliability and performance.

| Feature/Aspect | SE Standard Hoist | PE Pre-Engineered Hoist | CE Custom-Engineered Hoist |

| Description | Designed for light to heavy duty applications. | Designed for medium to severe duty applications. | Designed for the most demanding applications. |

| Capacity Range | 3 to 15 tons | 5 to 40 tons | 5 to 250 tons |

| Key Features | Compact design, helical gearing, durable wheels, TEFC motors, NEMA 4/12 controls, safety limit switches. | High-efficiency gears, dual-flanged wheels, continuous duty motors, 20:1 drum to wire rope ratio, open winch design, VFD controls. | High-quality gearbox, durable brake system, robust drum construction, advanced wheels, custom VFD controls, safety features. |

| Price Range | $15,000 to $50,000 | $50,000 to $150,000 | $75,000 to $400,000 |

| Best Applications | Manufacturing plants, warehouses, maintenance facilities, light to medium duty industrial applications. | Heavy manufacturing, steel service centers, aerospace, defense, foundries, paper mills. | Steel industry, shipyards, heavy manufacturing, aerospace, and defense. |

| Advantages | Cost-effective, easy maintenance, reliable performance. | Versatile design, robust construction, and customization options. | Highly customizable, robust construction, advanced features. |

| Downsides | Limited customization, capacity limitations, and standard features. | Higher initial cost, maintenance requirements, limited to 40 tons. | Higher cost, specialized maintenance, complex installation. |

Final Thoughts

By understanding the unique features, advantages, and limitations of each hoist type, you can make an informed decision that best meets your specific needs.

Whether you require a standard, pre-engineered, or custom-engineered hoist, Mazzella has the expertise and products to provide the perfect lifting solution for your operation. Regardless of the hoist model you choose, you can expect a high quality, American-made product that meets or exceeds all industry standards, keeping your workers safe and productive.

Contact one of our in-house Crane and Hoist Specialists if you have further questions. Download our Overhead Cranes & Built-Up Hoists Brochure to learn more about our capabilities.