Does Dried Concrete on Web Slings Require Removal From Service?

Does dried concrete on a synthetic web sling meet removal from service criteria? To best answer this question, Mazzella Companies rigging specialists need to conduct an in-person visual inspection.

Does dried concrete on a synthetic web sling meet removal from service criteria?

The answer isn’t a simple “yes” or “no.”

If you’re in the construction industry, concrete hardening on your synthetic web slings could be a common occurrence. You need to know this information because you’re looking to make secure lifts with the safety of your workers at the forefront at all times.

We want to help you make safe lifts, and to do that, we’ll answer the following questions:

- Does dried concrete meet removal from service criteria?

- What constitutes removal from service criteria?

- How can I maximize the life of my web slings?

- What are the inspection requirements for web slings?

Does Dried Concrete Meet Removal From Service Criteria on a Synthetic Web Sling?

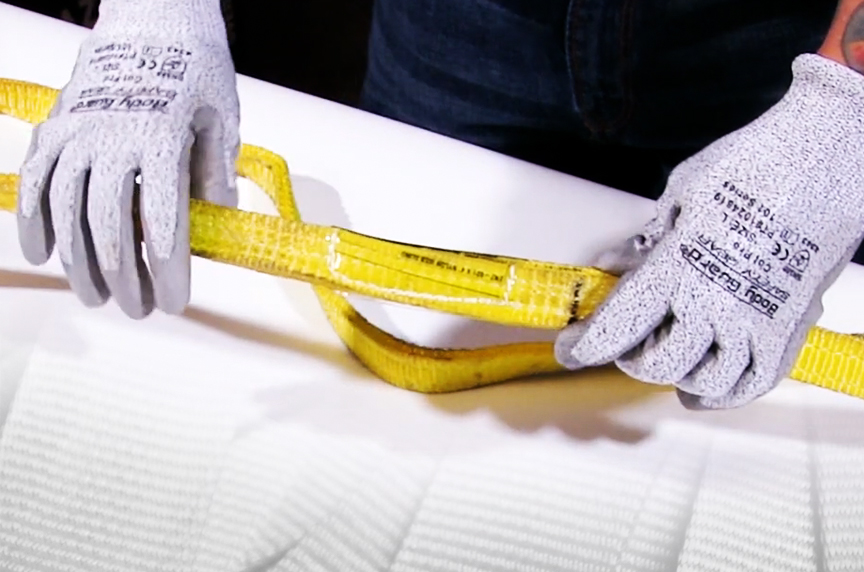

To make an accurate judgment on this question, our lifting specialists need to do an in-person inspection.

One of the disadvantages our experts have found is the webbing material itself is doing the lifting. What we’d look at during inspections of synthetic web slings is to see if that hardened concrete affected the webbing material’s ability to lift the load through cutting, holes, abrasions, or damage to the stitches themselves.

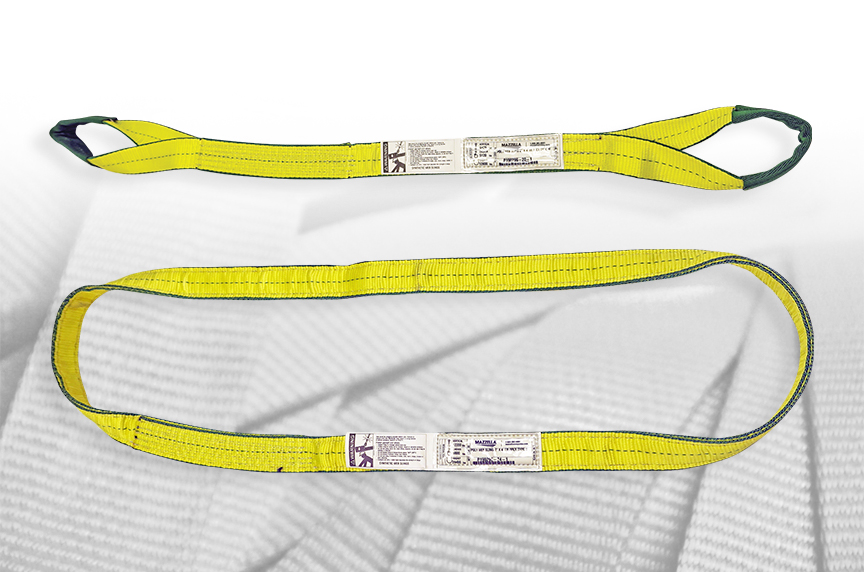

If you’re frequently at risk for concrete splatter to get on your slings, you might want to consider switching to a polyester roundsling, which has a double jacket around it. While the jackets don’t do anything to contribute to the lifting capacity, they protect the fibers on the inside, which are load-bearing.

With the double jacketing, you have added layers of protection. If concrete got on the jacket, it wouldn’t adversely affect those lifting fibers.

What Constitutes Removal From Service Criteria For Synthetic Web Slings?

While dried concrete on a synthetic web sling may or may not meet removal from service criteria, there are several instances that don’t require a secondary inspection before being retired.

According to the ASME B30.9 Slings standard, a synthetic web sling shall be removed from service if any of the following are visible:

- Missing or illegible sling identification tags

- Acid or alkalis burns

- Melting, charring or weld splatter on any part of the sling

- Holes, tears, cuts, snags or embedded particles

- Broken or worn stitching in load bearing splices

- Excessive abrasive wear

- Knots in any part of the sling

- Distortion, excessive abrasive wear

- Any conditions which cause doubt as to the strength of the sling

How Can I Maximize the Service Life of My Synthetic Web Slings?

Now that you know about removal from service criteria, there are several operating best practices recommended for synthetic web slings. These best practices will help your web slings reach their expected lifespan.

Knowing more about your lifts will help you improve the safety of your operations. Other recommendations cover basic maintenance of your rigging gear.

Here are several things to consider when taking care of your synthetic web slings:

Knowledge of Lifts

- Determine weight of the load. The weight of the load shall be within the rated capacity of the sling.

- Select slings having suitable characteristics for the type of load, hitch and environment.

- Slings shall not be loaded in excess of the rated capacity. Consideration shall be given to the sling-to-load angle, which affects rated capacity. (See load charts.)

- Slings with fittings, which are used as a choker hitch, shall be of sufficient length to ensure the choking action is on the webbing and never the fitting.

- Slings used in a basket hitch shall have the load balanced to prevent slippage.

- The opening in fittings shall be the proper shape and size to ensure the fitting will seat properly in the hook or other attachments.

- The sling’s legs (branches) shall contain or support the load from the sides above the center of gravity when using a basket hitch.

- Slings shall be long enough so the rated capacity of the sling is adequate when the angle of the legs (branches) is taken into consideration (see load charts).

- Shock loading shall be avoided.

- Twisting and kinking the legs (branches) shall be avoided.

- The load applied to the hook shall be centered in the base (bowl) of the hook to prevent point-loading on the hook.

Protecting the Synthetic Web Slings

- Slings shall always be protected from being cut by:

- Corners

- Edges

- Protrusions

- Abrasive surfaces

- Slings shall not be dragged on the floor or over an abrasive surface.

- Synthetic web slings shall not be twisted or tied into knots or joined by knotting.

- Slings shall not be pulled from under loads if the load is resting on the sling.

- Do not drop slings equipped with metal fittings.

- Slings that appear to be damaged shall not be used unless inspected and accepted.

- The sling shall be hitched in a manner providing control of the load.

Personnel Factors

Personnel, including portions of the human body, shall:

- Be kept from being between the sling and the load, and from between the sling and the crane hook or hoist hook.

- Stand clear of the suspended load.

- Not ride the sling.

- During lifting, with or without the load, be alert for possible snagging.

What Are the Inspection Requirements for Synthetic Web Slings?

Conducting sling inspections is key to finding potential damage in your synthetic web slings that could meet removal from service criteria.

It’s important to know that not all inspections require documentation. However, the inspections are listed in the ASME standards as best practices to ensure your company is conducting safe overhead lifts.

There are three types of inspections that your slings need:

- Initial inspection

- Frequent inspection

- Periodic inspection

Initial Inspection (Prior to Initial Use)

Best practice is to inspect synthetic web slings upon receiving them from the manufacturer. Double-check the sling tag to make sure it’s what you ordered, and that the rated capacity meets all of your project specifications and lifting requirements.

Frequent (Daily or Prior to Use)

Designate a Competent Person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and attachments for damage, defects, or deformities. The inspector should ensure the web sling selected meets the specific job requirements for which it’s being used.

However, users can’t rely on a once-a-day inspection if the web sling is used multiple times throughout the day. Shock loads, severe angles, edges, and excessive heat quickly can damage the webbing material. Best practice is to visually inspect synthetic web slings before any shift change or changes in lifting applications.

Periodic Inspection

A periodic inspection is performed either by a professional service provider, or Qualified Person every 12 months (at a minimum), and monthly to quarterly in more severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:

- Frequency of use

- Severity of service conditions

- Nature of the lifts being performed

- Experience gained on the service life of web slings used in similar applications

ASME provides these additional periodic inspection guidelines based on the service of the synthetic web sling:

- Normal Service – Yearly

- Severe Service – Monthly to Quarterly

- Special Service – As recommended by a Qualified Person

Depending on the severity of the operating environment and frequency of use, your business may decide to inspect synthetic web slings more often than the minimum yearly requirement.

Periodic inspections are required to be documented per ASME B30.9 Slings and records retained. The employer is required to maintain a record of the most recent thorough inspection—however, individual records for each synthetic web sling that was inspected are not required. Failure to maintain and retain inspection records is one of the most common issues we see that can prevent a company from reaching full OSHA compliance.

What’s Your Next Step?

First things first, you need a designated person on-site to conduct frequent visual inspections. Remember to do these visual inspections at least once per shift, and even more frequently should the lifting conditions/activities change. These inspections could be the difference between a safe lift, and a catastrophic incident.

After conducting those visual inspections, if you have questions about a synthetic web sling meeting removal from service criteria, pull it out of use and contact a lifting specialist.

Following an inspection, you can put a web sling that doesn’t meet the criteria back into service. Ignoring removal from service criteria could result in a completely preventable, and potentially life-changing accident.

Our rigging inspection service technicians dedicate their time to helping customers answer questions, follow best practices, and use safe rigging gear. We know the removal from service standards, and by doing proper inspections, can determine if your slings meet that criteria.

Call us today at 800.362.4601 or click here to speak with a Mazzella Lifting Specialist, or book your next required inspection.

Rigging Inspection Services

OSHA 1910.184, ASME B30.9, B30.20, B30.26, and ANSI Z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions.

Our team of rigging inspectors are certified to make sure your products meet OSHA and ASME requirements.

Copyright 2021. Mazzella Companies.