How Much Does a Warehouse Rack Inspection Cost?

Whether you’re comparing quotes or trying to budget, this page gives you the clarity most providers avoid.

You’ll see what affects inspection pricing, what’s actually included, and how to get the best value, without cutting corners or facing surprise charges. You’ll also know what to expect before anyone sets foot in your facility, with guides, tools, and FAQs to help you make the smartest decision for your team and company.

Pallet Racking Inspection Pricing

| Length | Size | Rate |

|---|---|---|

| 1-Day | Home Depot / Lowes Sized Facility | $6,800 – $7,800 |

| 2-Day | Large Distribution Center | $7,800 – $9,800 |

All inspections are quoted on a port-to-port basis — this includes travel time from the nearest Mazzella location, on-site inspection time, and return. Multi-inspector jobs are more efficient for large facilities or the location of the facility. We’ll recommend the right team size based on your equipment volume, location, and timeline.

What’s Included In Your Detailed Inspection?

Our inspections follow the intent of ANSI MH16.1-2023 and assess your racking systems for structural integrity, safe usage, and compliance with best practices in design and utilization.

- Each inspection includes:

- Structural review of frames, beams, braces, and anchors.

- Load condition analysis: overloading, deflection, improper pallet support.

- Missing or damaged components: beam locks, anchors, row spacers.

- Unapproved modifications: field welds, repairs without engineering input.

- Rack-to-product compatibility and usage alignment.

- You receive a detailed report with:

- Color-coded severity ratings (Red, Orange, Yellow, Black).

- Photos and descriptions of findings.

- Corrective action recommendations.

We inspect all rack types — including drive-in, push-back, flow, and mixed systems — even where ANSI MH16.1 may not apply directly.

Factors That Affect Inspection Cost

Contact Our Inspections Team

Frequently Asked Questions

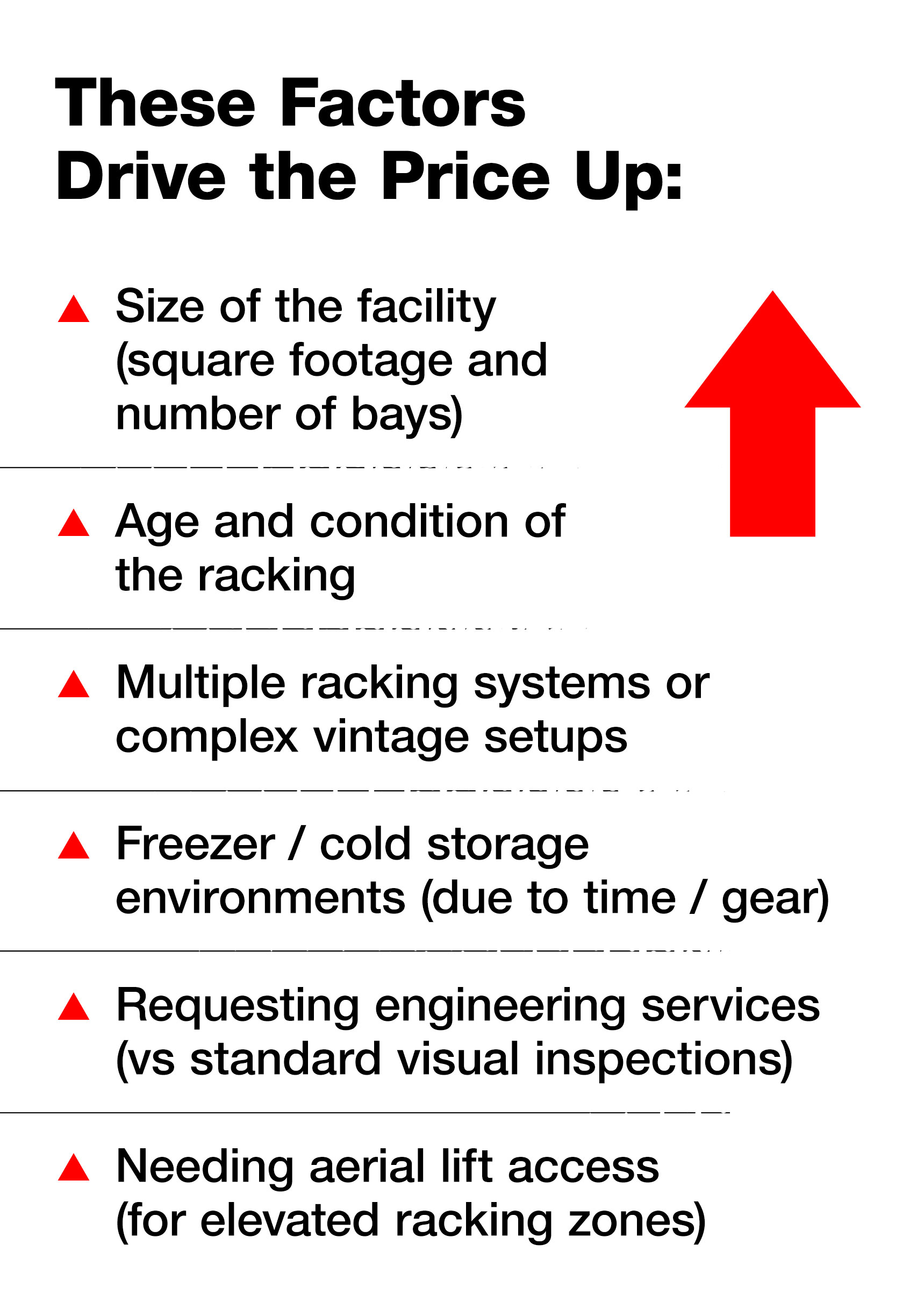

What factors drive the price up?

Several factors can increase the total cost of a rack inspection:

- Size of the facility (square footage and number of bays).

- Age and condition of the racking.

- Multiple racking systems or complex vintage setups.

- Freezer / cold storage environments (due to time / gear).

- Requesting engineering services (vs standard visual inspections).

- Needing aerial lift access (for elevated racking zones).

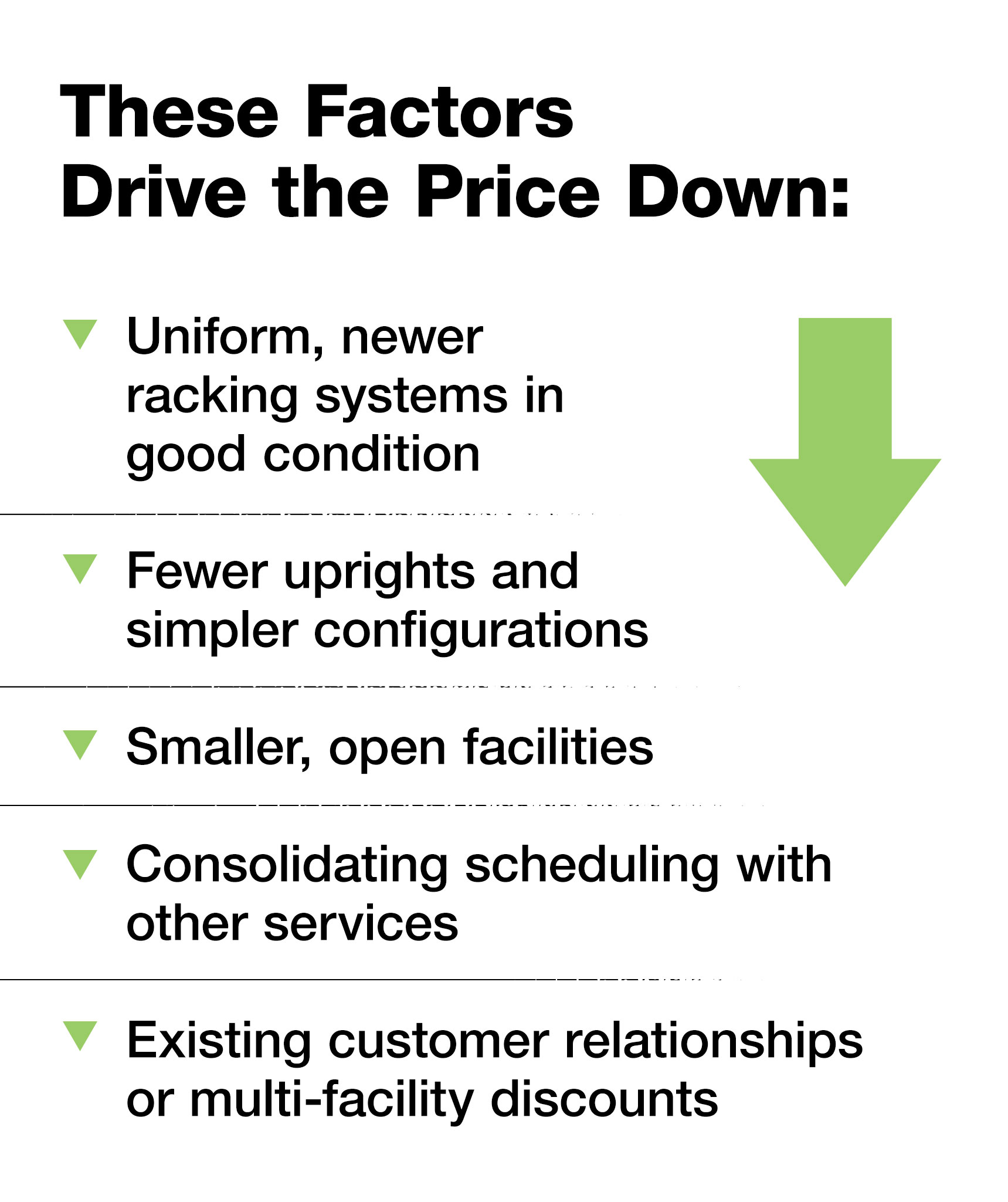

What factors drive the price down?

Warehouse racking inspection costs can be reduced if:

- Uniform, newer racking systems in good condition.

- Fewer uprights and simpler configurations.

- Smaller, open facilities.

- Consolidating scheduling with other services.

- Existing customer relationships or multi-facility discounts.

What makes some companies so expensive?

Higher-priced inspection providers often offer:

- More comprehensive deliverables, including detailed reports, photos, and post-inspection consulting.

- Specialized training or engineering involvement.

- Experience with complex or regulated environments, like freezer storage or seismic zones, where inspections are more involved.

- Faster turnaround or priority scheduling.

What makes some companies so cheap?

Some low-cost providers use a basic checklist approach, skip post-inspection follow-ups, or don’t include documentation — leaving safety gaps unaddressed.

Low-cost or “free” racking inspections often come with major trade-offs:

- Low-experience inspectors with little compliance knowledge.

- No reporting — just a walk-through with no documentation.

- No consultation or follow-up planning.

- Rushed jobs with minimal review.

Caution: “Free” inspections can be costly if they miss compliance gaps or expose you to liability.

Why does packaging vary in the industry?

Mazzella provides a fully consultative inspection including structural review, fasteners, product application, and missing components. You also get color-coded severity rankings and support from specialists in rack design.

- On-site walk-through.

- Pre- and post-inspection calls.

- A full written report with findings, compliance issues, photos, and recommendations.

- Help creating a corrective action plan.

- Consulting on forklift operator training if necessary.

Other providers may skip one or more of these steps.

Lifetime Cost vs. Initial Price

A racking inspection may seem like a line item, but it often prevents tens or even hundreds of thousands in unplanned costs. The cost of a rack inspection is a fraction of the cost of a warehouse incident. Even though rack inspections aren’t required by law, skipping them can lead to injuries, inventory loss, shutdowns, or worse.

These inspections can help you avoid:

- OSHA fines.

- Product damage.

- Worker injuries.

- Downtime.

- Increased Insurance Premiums.

But the real value goes deeper.

During the inspection, we often uncover training gaps—like unsafe loading habits, improper product application or rack loading, poor fork truck operation, fork truck pinch points, or missed daily inspections — that aren’t obvious until someone’s analyzing your rack damage.

Identifying those gaps early allows you to correct behaviors before they become incidents, which has a long-term ripple effect on safety, uptime, and team confidence.

In short, you’re not just paying to find damage. You’re investing in preventing the next dangerous accident or failure and building a safer, smarter team in the process.

Have racking inspection rates changed recently?

- Pricing has been stable year-over-year.

- Customers on recurring inspection plans can expect consistent pricing, unless scope changes.

Are there discounts? What are the payment options?

- No upfront payment required — standard net terms billing through Mazzella.

- Discounts for multi-facility inspections or bundling services.

What’s included in the warehouse racking inspection cost?

Mazzella’s inspections follow the intent and guidance of ANSI MH16.1-2023, the recognized standard for the design, testing, and utilization of industrial steel storage racks. While this standard outlines design criteria—not inspection protocol per se—it defines what constitutes structural adequacy and acceptable rack configuration. Our inspection process is designed to evaluate real-world rack conditions against that intent.

Every Mazzella racking inspection includes:

- Travel (except extreme cases- West coast, Hawaii / International, etc.).

- On-site safety inspection of warehouse racking by experienced specialists.

- Pre-inspection consult to understand site layout, scope, and goals.

- Post-inspection debrief with safety recommendations and guidance.

- Comprehensive report (PDF) detailing:

- Structural Integrity:

- Visual review of frames, beams, anchors, and braces.

- Identification of bent, twisted, or cracked components.

- Check for excessive beam deflection, sheared anchors, and broken welds.

- Evaluation of compromised load paths or collapsed geometry.

- Rack Loading and Product Interface:

- Signs of overloading, off-center or point-loaded pallets.

- Inadequate pallet support (gaps, overhang, or unsupported product).

- Loads exceeding the rated design (where verifiable).

- Fasteners and Safety Devices:

- Missing or disengaged beam locks, bolts, and safety pins.

- Loose or damaged anchors, especially post-impact.

- Improper hardware substitutions or repairs.

- Missing Components:

- Absent crossbars, mesh decks, pallet stops, or row spacers.

- Unanchored tunnel bays that should be protected.

- Critical accessories removed or displaced.

- Improper Modifications:

- Field welds, added bracing, or repair kits without engineering review.

- Post-impact repairs done without reference to manufacturer specs.

- Items welded directly to frame members.

- Product Application and Compatibility:

- Ensures rack type aligns with product load and handling method.

- Identifies mismatches between original intent and current usage.

- Structural Integrity:

- Support with safety planning and follow-up remediation options:

- A detailed written report with color-coded severity ratings:

- BLACK: No issue.

- YELLOW: Monitor for future damage.

- ORANGE: Prioritized repairs needed.

- RED: Immediate hazard, unload immediately.

- Site-specific recommendations.

- Photos and descriptions of each finding.

- Pre- and post-inspection communication to ensure alignment and corrective planning.

- A detailed written report with color-coded severity ratings:

🔍 There is no standardized format in the industry — Mazzella sets itself apart with highly detailed reporting and real consultative guidance, not a generic checklist.

Are there any hidden costs?

- No hidden fees. Once quoted, the price does not change — even if you underestimated your scope.

- The only exception: if your scope significantly changes after the agreement (e.g., adding on multiple additional buildings). Travel is included in most quotes, except in edge cases (e.g., Hawaii, West Coast, international). These are discussed transparently up front.

- How we can offer this guarantee:

- We do our due diligence upfront. That includes asking the right questions, reviewing photos, and sometimes even doing a walkthrough. If we miss something in the quoting process, we take responsibility — not you.

- Cancellation policy:

- If travel hasn’t been booked, you can cancel at no charge. If travel has already been arranged, a cancellation fee may apply to recover those costs.

Why should I budget for qualified third-party racking inspections?

Rack inspections aren’t legally required—but when a safety issue halts operations, injures a worker, or causes inventory loss, the cost far exceeds the inspection. This is about protecting your people, product, and profit.

Even though inspecting your racks is not required by law, if an accident occurs and OSHA finds out you have not inspected your racks, you can still be held liable and fined under OSHA’s General Duty Clause.

OSH Act of 1970 SEC. 5. Duties:

- (a) Each employer —

- (1) shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

- (2) shall comply with occupational safety and health standards promulgated under this Act.

- (b) Each employee shall comply with occupational safety and health standards and all rules, regulations, and orders issued pursuant to this Act which are applicable to his own actions and conduct.

How to Prepare for Your Inspection

Preparation improves inspection quality and efficiency. Here’s how to get ready:

- Help us coordinate with your Safety Department to complete any required on-site safety training.

- Clear visual access to racking: move product and equipment as much as possible to allow us access.

- Provide photos or a layout before the visit (to help determine if 1-day or 2-day inspection is needed).

- If available, have a team member familiar with your racking history on hand.

⚠️ Preparation helps avoid scope surprises, reduces inspection time, and protects your investment in safety.

Why Mazzella?

Unlike many “checklist” inspections, Mazzella offers:

- Decades of rack-specific expertise — this is a highly specialized skill without official qualifications in most regions.

- Consultative approach: We don’t just point out problems — we help solve them.

- Clear, prioritized reports with visual documentation and color-coded severity levels.

- National footprint to serve multiple facilities consistently.

- Experience across all racking types: selective, push-back, drive-in, cantilever, VNA, and vintage / consolidated systems.

- Engineering support available for advanced or heavily modified systems.

Whether you’re scaling, consolidating, or upgrading — Mazzella helps you understand what’s safe, what’s not, and what to do next.