How Much Does a Rigging Inspection Cost?

Whether you’re comparing quotes or trying to budget, this page gives you the clarity most providers avoid.

You’ll see what affects inspection pricing, what’s actually included, and how to get the best value, without cutting corners or facing surprise charges. You’ll also know what to expect before anyone sets foot in your facility, with guides, tools, and FAQs to help you make the smartest decision for your team and company.

Rigging Inspection Pricing

| Number of Techs | Half Day | Full Day |

|---|---|---|

| 1 | $480 – $600 | $960 – $1,200 |

| 2 | $960 – $1,200 | $1,920 – $2,400 |

| 3 | $1,440 – $1,800 | $2,880 – $3,600 |

All inspections are quoted on a port-to-port basis—this includes travel time from the nearest Mazzella location, on-site inspection time, and return. Multi-inspector jobs are more efficient for large facilities or the location of the facility. We’ll recommend the right team size based on your equipment volume, location, and timeline.

What’s Included In Your Detailed Inspection?

- All applicable OSHA and ASME standards, including ASME B30.9, B30.10, B30.20, B30.21, B30.26, HST-2 and OSHA 1926.502.

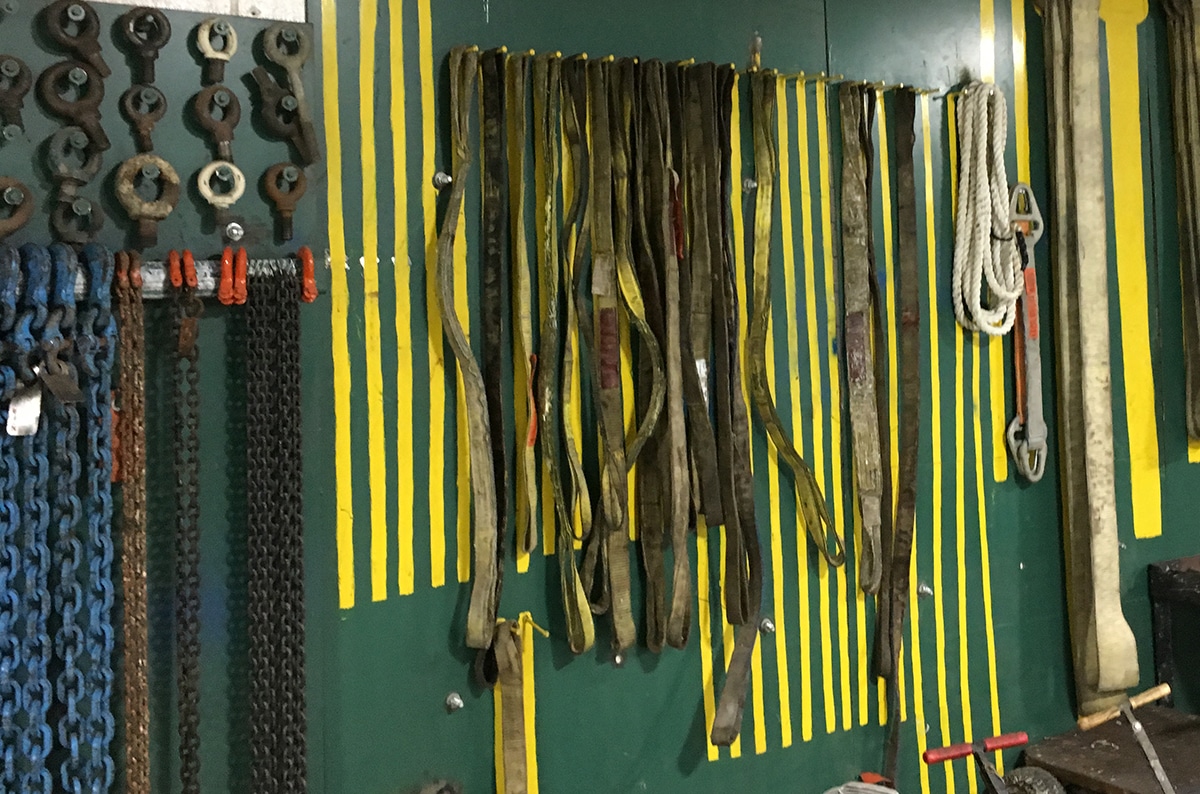

- Visual inspection of all rigging equipment including slings, hardware, shackles, below-the-hook devices, manual hoists and pullers, fall protection soft goods, and more.

- Reporting of each item: pass, repair, or scrap — based on condition and compliance.

- Documentation of serial numbers, manufacturer, capacity, and condition for inspected items.

- Written inspection report that exceeds minimum standards.

- Preparation of formal repair quotes, if repairs are requested post-inspection.

- Coordination with your team to ensure safe access and review of final results.

- Post-inspection support to interpret results and assist with corrective action planning.

Factors That Affect Inspection Cost

Contact Our Inspections Team

Frequently Asked Questions

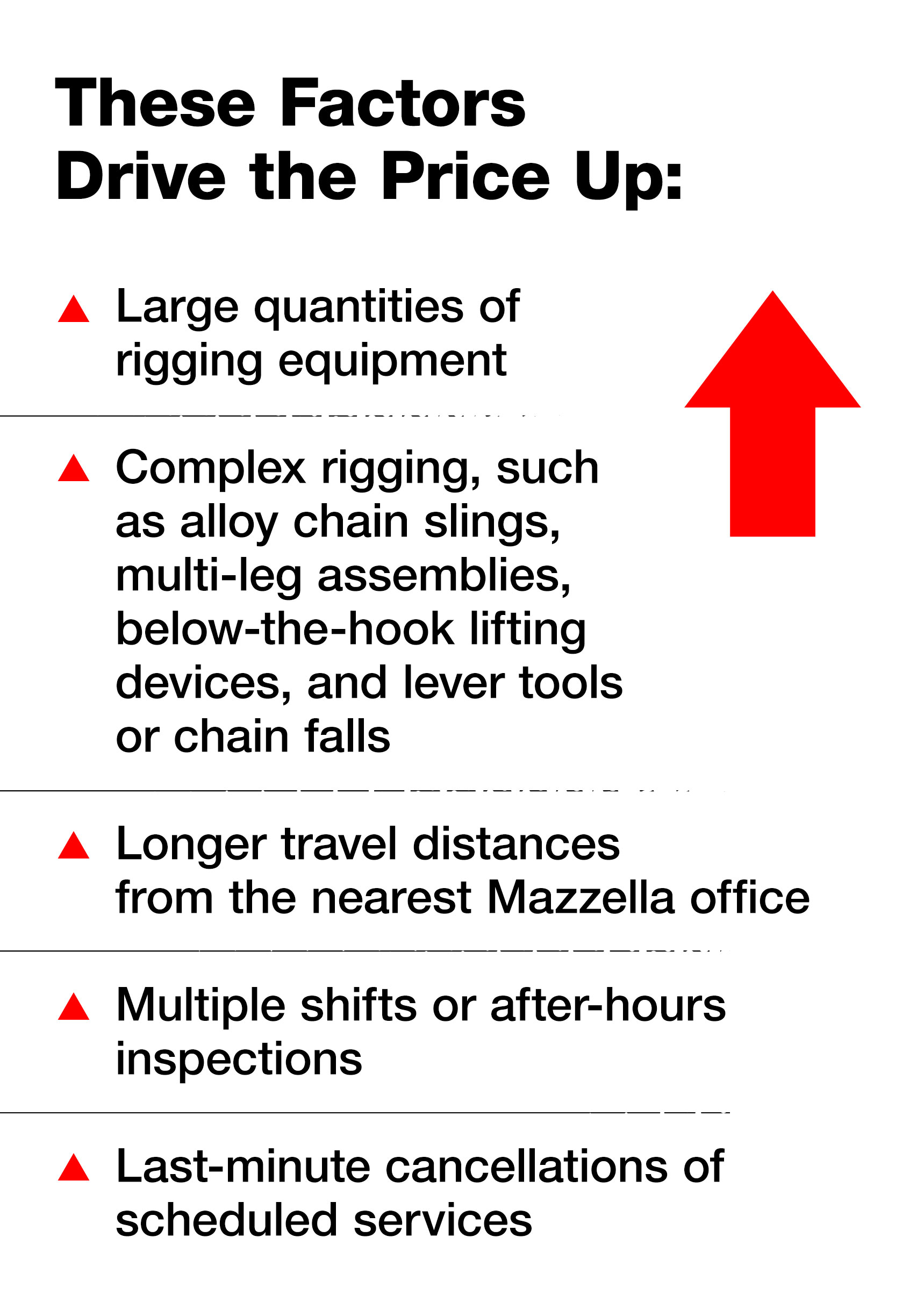

What factors drive the price up?

Several factors can increase the total cost of a rigging inspection:

- Large quantities of rigging equipment to inspect.

- Complex rigging, such as alloy chain slings, multi-leg assemblies, below-the-hook lifting devices, and lever tools or chain falls.

- Longer travel distances from the nearest Mazzella office.

- Multiple shifts or after-hours inspections.

- Incomplete or inaccurate equipment lists at the time of inspection.

- Last-minute cancellations of scheduled services.

- Additional NDT (Non-Destructive Testing) requested — increases inspection time.

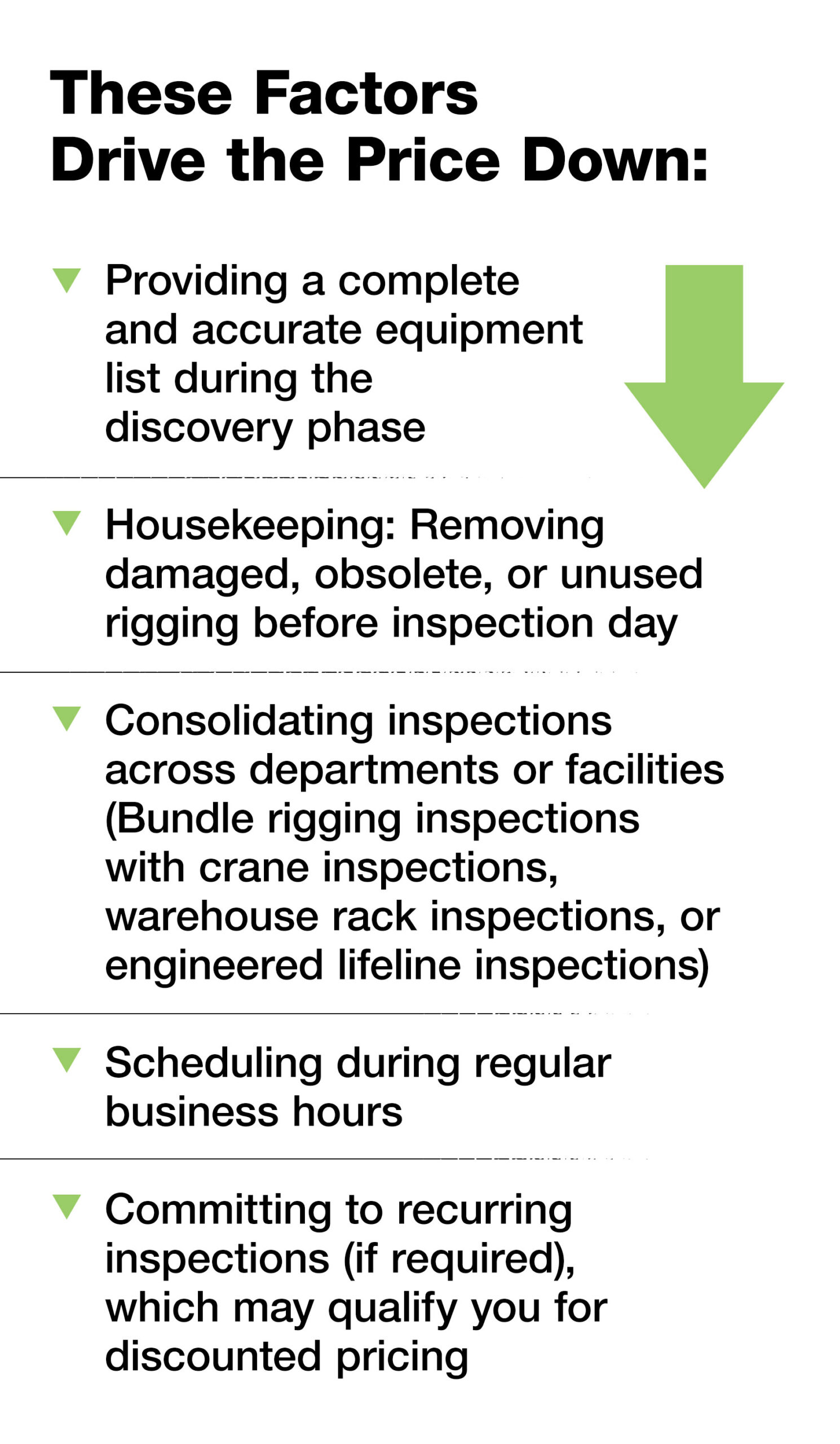

What factors drive the price down?

You can reduce your rigging inspection cost by:

- Providing a complete and accurate equipment list during the discovery phase.

- Housekeeping: Removing damaged, obsolete, or unused rigging before inspection day.

- Consolidating inspections across departments or facilities (Bundle rigging inspections with crane inspections, warehouse rack inspections, or engineered lifeline inspections).

- Scheduling during regular business hours.

- Committing to recurring inspections (if required), which may qualify you for discounted pricing.

What makes some companies so expensive?

Higher-priced inspection providers often offer:

- Qualified, full-time rigging inspectors with ongoing training and certification.

- Thorough documentation of every item — not just the basics.

- Compliance programs that exceed OSHA and ASME standards.

- Internal systems for reporting, tracking, and continuous improvement.

- A “no upsell” policy — inspection is not a sales tool.

What makes some companies so cheap?

Low-cost or “free” rigging inspections often come with major trade-offs:

- Skipping critical items like below-the-hook devices or fall protection.

- Underqualified inspectors or borrowed sales staff.

- Minimal documentation (handwritten notes or incomplete reports).

- Focused on selling equipment, not ensuring compliance.

- Increased risk exposure if OSHA audits your facility.

Caution: “Free” inspections can be costly if they miss compliance gaps or expose you to liability.

Why does packaging vary in the industry?

| Factor | Mazzella | Some Competitors |

|---|---|---|

| Business Model | Dedicated inspection division | Bundled “freebie” service |

| Compliance Standards | Meets/exceeds OSHA and ASME | Varies widely |

| Documentation | Every item documented | Often limited or partial |

| Staff | Qualified, trained inspectors | Sales personnel |

| Transparency | Fixed quotes, no surprises | Variable or vague pricing |

Lifetime Cost vs. Initial Price

Rigging inspections are a required operational expense, but they return value through:

- Avoided OSHA fines and violations.

- Lower failure rates and downtime.

- Improved worker safety and training.

- Reduced liability exposure.

Important: One missed inspection can cost tens of thousands in downtime or worse. A $1,000 inspection protects your business and your people.

Have rigging inspection rates changed recently?

Rigging inspection pricing has remained relatively stable over recent years. When pricing changes occur, they are typically driven by:

- Increases in fuel or travel costs.

- Shifts in insurance and liability expenses.

- Rising labor or certification requirements.

Note: All pricing changes are clearly communicated through updated, formal quotes.

Are there discounts? What are the payment options?

- Formal quotes with port-to-port pricing.

- Purchase order billing structure.

- Discounts available for committed, recurring inspections.

- No hidden fees or bait-and-switch tactics.

What’s included in the rigging inspection cost?

Every Mazzella rigging inspection includes:

- Trained, experienced, and certified inspectors.

- Full compliance with applicable OSHA and ASME standards:

- ASME B30.9, B30.10, B30.20, B30.21, B30.26

- HST-2, OSHA 1926.502

- Inspection of all applicable rigging equipment:

- Slings (synthetic, wire rope, alloy chain, mesh).

- Below-the-hook devices.

- All rigging hardware covered under ASME B30.26 and B30.10.

- Manual hoists: chain falls, lever tools (not installed at height).

- Personal fall protection equipment — harnesses, lanyards, SRLs, confined space tripods.

- Reporting of all inspected items: Pass / Fail.

- Tagging and removal of failed items — Repair / Scrap.

- Comprehensive digital inspection report (PDF).

- Clear documentation of compliance status by item.

What if we cancel or underestimate our equipment?

We’ll work with you — but large last-minute changes or underreporting may result in scope-based quote adjustments.

Why should I budget for qualified third-party rigging inspections?

Some ask, “Can we afford to do this?”

A better question: Can you afford not to? First and foremost documented periodic rigging inspections are required by law.

Neglecting required inspections creates:

- OSHA violations and fines.

- Increased failure rates.

- Denied insurance claims.

- Personal and company liability.

- Risk to your people.

If there’s an incident and you didn’t inspect — when you knew you had to — you’ve not only failed compliance, you’ve exposed yourself and your team.

How to Prepare for Your Inspection

Set your inspection up for success by:

- Submitting an accurate frontload count of rigging items by type.

- Removing any damaged or obsolete gear.

- Ensuring inspection zones are clean and accessible.

- Informing us of PPE, safety training, or escorted access requirements.

- Communicating inspection priorities (by department or area).

Why Mazzella?

- 3,000+ inspections / year.

- Over 250,000+ rigging items inspected per year.

- Every major industry served — from steel mills to ski resorts.

- Full time inspection business. No sales pitches. Just documentation that protects your team.

![Rigging Gear Inspection Field Reference [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-rigging-gear-inspection-field-reference-guide-0324.jpg)

![A Guide to Sling Inspections and OSHA & ASME Standards [e-book]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-sling-inspection-e-book-0324.jpg)

![Lifting & Rigging Inspection Frequencies & Records [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-inspection-frequencies-guide-0324.jpg)

![OSHA Personnel Designations [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2022/09/resource-download-osha-designations-guide.jpg)

![How to Dispose of Damaged Rigging Gear [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-disposal-of-rigging-gear-guide-0324.jpg)