Description

Features and Benefits:

- High strength

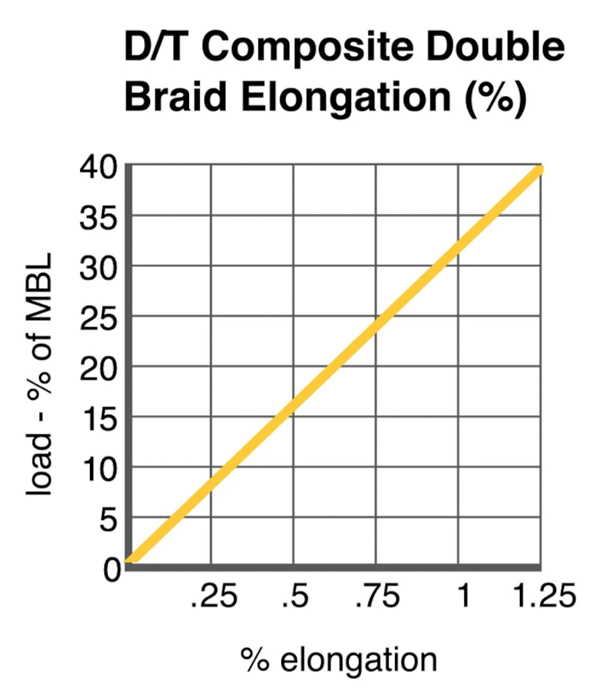

- Low stretch

- Soft hand

- Torque free

- Easy splicing

Applications:

- Winch lines

- Crane lines

- Theatrical rigging

- Utility pulling lines

Certifications:

- ABS

- DNV-GL

| Nominal Diameter (inches) |

Size (circ in.) |

Approximate Weight (lbs/100ft) |

Minimum Tensile Strength Spliced Rope (lbs) |

Minimum Tensile Strength ISO Unspliced Rope (lbs) |

|---|---|---|---|---|

| 7/16 | 1-1/4 | 6.1 | 14,850 | 16,500 |

| 1/2 | 1-1/2 | 8.3 | 20,925 | 23,300 |

| 9/16 | 1-3/4 | 10.1 | 28,200 | 31,300 |

| 5/8 | 2 | 12.5 | 36,900 | 41,000 |

| 3/4 | 2-1/4 | 15.9 | 47,250 | 52,500 |

| 7/8 | 2-3/4 | 24.9 | 67,200 | 74,700 |

| 1 | 3 | 30.8 | 77,400 | 86,000 |

| 1-1/8 | 3-1/2 | 36.8 | 98,250 | 109,200 |

| 1-1/4 | 3-3/4 | 42.6 | 109,050 | 121,200 |

| 1-5/16 | 4 | 49.7 | 119,250 | 132,500 |

| 1-1/2 | 4-1/2 | 64 | 150,000 | 166,700 |

| 1-5/8 | 5 | 76 | 180,000 | 200,000 |

| 1-3/4 | 5-1/2 | 89.8 | 208,000 | 231,100 |

| 2 | 6 | 107 | 247,500 | 275,000 |

Tensile Strengths are determined in accordance with Cordage Institute 1500, Test Methods for Fiber Rope. Weights are calculated at linear density under standard preload (200d2) plus 4%. See reverse side for application and safety information.

Technical Information

Specific gravity: 1.20*

Melting point: 284°F (140°C)

Critical temperature: 150°F (65°C)

Coefficient of friction: 0.12–0.15*

Elongation at break: 3%–4%

Fiber water absorption: 0–1%

UV resistance: excellent

Wet abrasion: excellent

Dry abrasion: excellent

* Value based on data supplied by the fiber manufacturer for new, dry fiber