Description

Features and Benefits:

- World’s strongest rope for its weight

- Long lengths available

- High flex fatigue and abrasion resistance

- Easy to splice, inspect, and repair

- Neutrally buoyant in water

- Select sizes are ABS & DNV type approved

Applications:

- Replacement for wire rope heavy lift slings

- Tug vessel assist lines

- Vessel mooring lines

- Offshore working ropes

- Lashings

Certifications:

- ABS

- DNV-GL

| Nominal Diameter (inches) |

Size (circ in.) |

Approximate Weight (lbs/100ft) |

Minimum Tensile Strength Spliced Rope (lbs) |

Minimum Tensile Strength ISO Unspliced Rope (lbs) |

|---|---|---|---|---|

ABS and DNV type approved sizes — up to 4” diameter (96 mm) |

||||

| 1-5/8 | 5 | 66 | 291,000 | 323,300 |

| 1-3/4 | 5-1/2 | 78 | 314,000 | 348,900 |

| 2 | 6 | 91 | 355,000 | 392,450 |

| 2-1/8 | 6-1/2 | 109 | 428,000 | 475,600 |

| 2-1/4 | 7 | 122 | 481,000 | 534,400 |

| 2-1/2 | 7-1/2 | 148 | 530,000 | 588,900 |

| 2-5/8 | 8 | 167 | 596,000 | 662,200 |

| 2-3/4 | 8-1/2 | 187 | 660,000 | 733,300 |

| 3 | 9 | 214 | 780,000 | 866,700 |

| 3-1/8 | 9-1/2 | 235 | 850,000 | 944,400 |

| 3-1/4 | 10 | 261 | 940,000 | 1,045,400 |

| 3-1/2 | 10-1/2 | 298 | 1,108,000 | 1,231,000 |

| 3-5/8 | 11 | 324 | 1,250,000 | 1,388,900 |

| 3-3/4 | 11-1/2 | 343 | 1,317,000 | 1,463,000 |

| 4 | 12 | 394 | 1,520,000 | 1,689,000 |

| 4-1/8 | 12-1/2 | 457 | 1,622,000 | 1,802,000 |

| 4-1/4 | 13 | 514 | 1,697,000 | 1,886,000 |

| 4-1/2 | 13-1/2 | 530 | 1,827,000 | 2,030,000 |

| 4-5/8 | 14 | 546 | 1,880,000 | 2,089,000 |

| 4-3/4 | 14-1/2 | 587 | 1,927,000 | 2,141,000 |

| 5 | 15 | 606 | 2,069,500 | 2,299,000 |

| 5-1/8 | 15-1/2 | 657 | 2,212,000 | 2,458,000 |

| 5-1/4 | 16 | 703 | 2,355,000 | 2,617,000 |

| 5-1/2 | 16-1/2 | 749 | 2,497,500 | 2,775,000 |

| 5-5/8 | 17 | 813 | 2,640,000 | 2,933,000 |

| 5-3/4 | 17-1/2 | 871 | 2,782,500 | 3,092,000 |

| 6 | 18 | 932 | 2,925,000 | 3,250,000 |

| 6-1/8 | 18-1/2 | 985 | 3,068,000 | 3,409,000 |

| 6-1/4 | 19 | 1038 | 3,210,500 | 3,567,000 |

| 6-1/2 | 19-1/2 | 1103 | 3,353,000 | 3,726,000 |

| 6-5/8 | 20 | 1159 | 3,496,000 | 3,884,000 |

| 6-3/4 | 20-1/2 | 1227 | 3,638,500 | 4,043,000 |

| 7 | 21 | 1284 | 3,781,000 | 4,201,000 |

| 7-1/8 | 21-1/2 | 1334 | 3,963,500 | 4,404,000 |

| 7-1/4 | 22 | 1392 | 4,066,000 | 4,518,000 |

| 7-1/2 | 22-1/2 | 1452 | 4,209,000 | 4,677,000 |

| 7-5/8 | 23 | 1527 | 4,351,500 | 4,835,000 |

| 7-3/4 | 23-1/2 | 1589 | 4,494,000 | 4,993,000 |

| 8 | 24 | 1653 | 4,637,000 | 5,152,000 |

| 8-1/8 | 24-1/2 | 1732 | 4,779,000 | 5,310,000 |

| 8-1/4 | 25 | 1798 | 4,922,000 | 5,469,000 |

Size: Diameter and circumference are nominal. A new unused rope in relaxed state will measure larger; loading and use compacts ropes, sets splices and lessens rope size. This is especially prevalent in sizes above 4″ diameter. Published nominal sizes from 4-1/8″ and larger represent stabilized or preloaded size.

Weights: Published weights of sizes 1-5/8″– 4″ diameter are calculated at linear density under stated preload (200d²) plus 4%. For this chart, sizes 4-1/8″–8-1/4″ diameter represent un-cycled, (non-stabilized) weights.

Tensile Strengths: Tensile strength determined in accordance with Cordage Institute 1500 Test Methods for Fiber Ropes and ISO 2307.

Technical Information

- Specific gravity: 0.98*

- Melting point: 284°F (140°C)

- Critical temperature: 150°F (65°C)

- Coefficient of friction: 0.09–0.12*

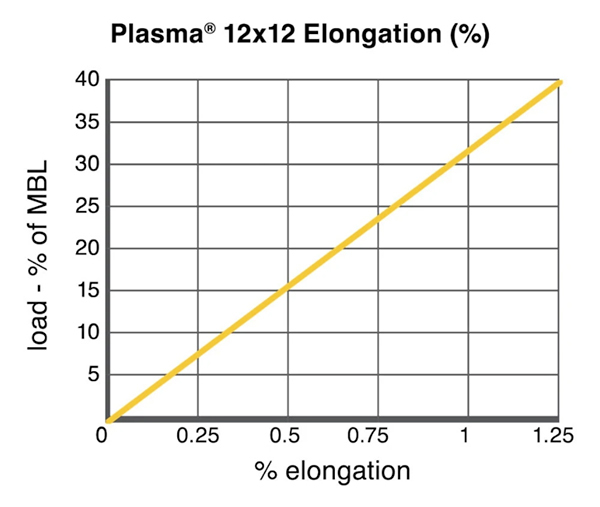

- Elongation at break: 3%–4%

- Fiber water absorption: 0%

- UV resistance: moderate

- Wet abrasion: superior

- Dry abrasion: superior

* Value based on data supplied by the fiber manufacturer for new, dry fiber